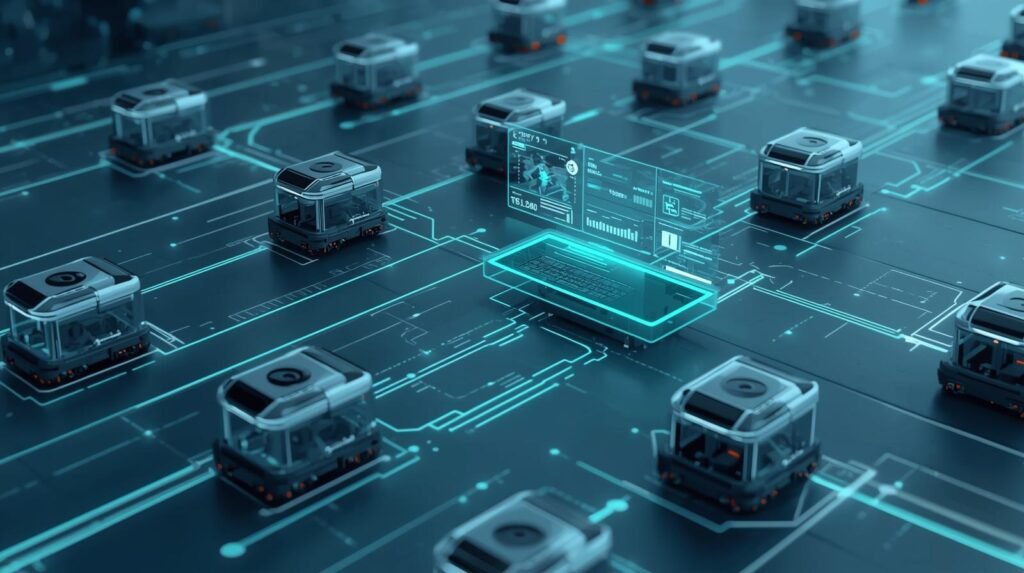

Do you ever wonder how your online purchase is selected from a million other products and is prepared for shipment within minutes of clicking “Buy”? The answer is not simply one robot; it is an orchestrated army of robots working together. However, if you are going to have an army, you will need someone to lead it. This is where the true magic occurs with a system known as Robot Fleet Management (RFM), which can be thought of as air traffic control for robots.

RFM is the central nervous system of your robotic workforce, directing each machine to its designated location, telling them what to do at all times, and when to do it. This is the essence of AMR fleet management: the unseen leader who takes a dozen or a hundred different robots and creates a single intelligent workforce.

Controlling a single robot is simple; however, managing a fleet of robots without a central controller would be chaotic. The robots would create gridlock in aisle traffic, compete for the same task, and stop dead in their tracks once their battery life reached zero. The operation would come to a standstill.

This guide outlines the 5-step process for robot fleet management. We will take you through the process of viewing your robots on a map to developing the entire operation over time and turning potential chaos into clockwork efficiency.

Summary

“Robot Fleet Management: A smart guide to running multiple robots efficiently with a central ‘Control Tower’ to manage tasks just like an air-traffic controller.”

This article takes the process of effectively managing large numbers of robots with a single “control tower,” which works much like an air-traffic controller, and divides it into five straightforward steps.

Step 1 is to view everything at once: a single dashboard displays every robot’s current position, status, and issues in real time. Step 2 emphasizes automated job assignments, in this case, the system assigns the next available job to the robot that can complete the job the fastest considering such things as the distance of the job site from the robot, the robot’s workload and its battery level; so humans assign the objectives for the job and the software determines which robot will do the job. Step 3 defines traffic rules that prevent robotic congestion by defining digital “rules of the road” for robots, including one-way lanes, right-of-way priority, and yielding behaviors.

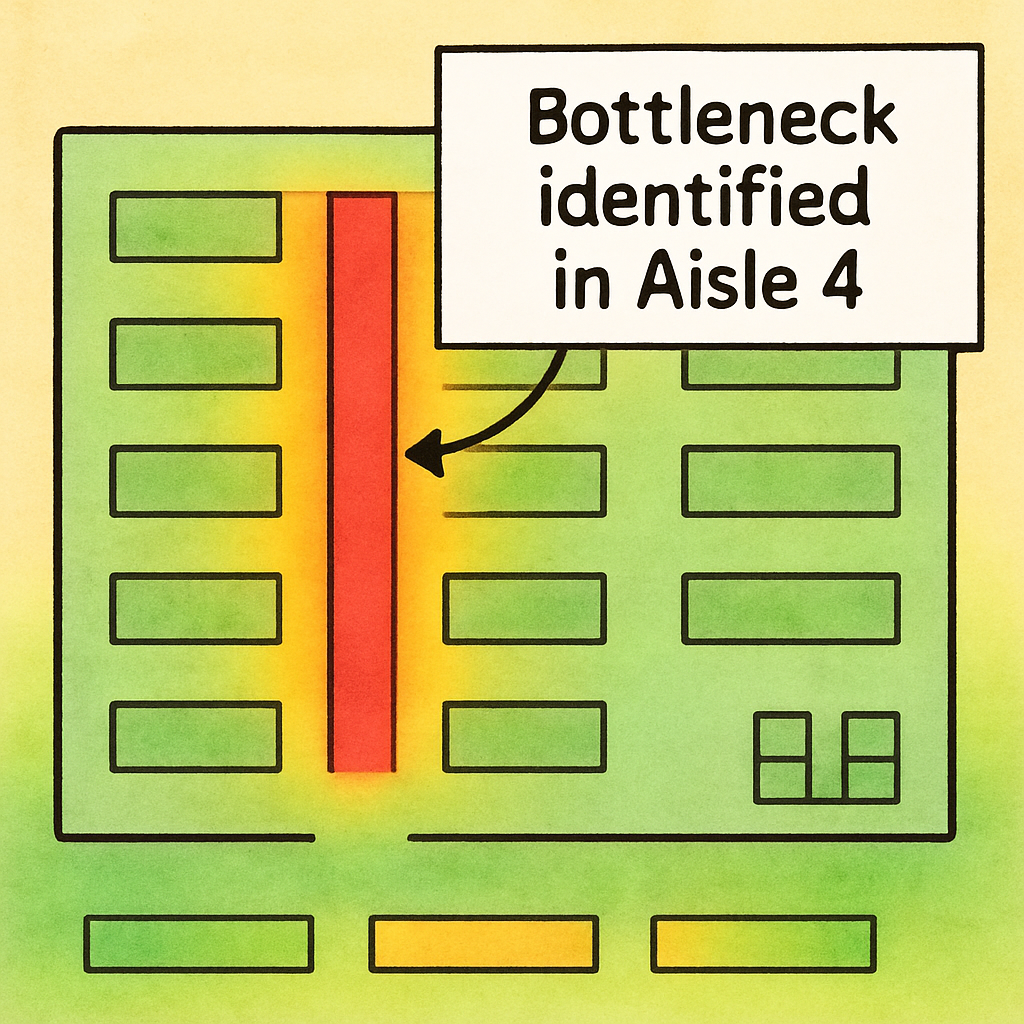

Step 4 defines the actions required to maintain fleet health by enabling automated charging and predictive maintenance, and by identifying potential wear and tear through monitoring and diagnostic tools before breakdowns occur. Step 5 converts operational data into opportunities for improvement by utilizing analytics (e.g., heat maps), to identify bottlenecks, improve layout and routing options, and support scaling decisions.

It should also be noted that, in addition to explaining the above process for managing robots, the article highlights the challenges of managing robots from different brands and the growing need for standardized interoperability across systems to support the management of multi-vendor fleets within a single system.

Robot Fleet Management

Robot Fleet Management is the coordination of all aspects of multiple robots (e.g., AMRs, AGVs, drones) to ensure safe, efficient, team-wide operation. With Robot Fleet Management, robots operate independently but communicate with each other via management software to assign tasks, monitor status, and enable free movement within a space.

Dispatching (assigning jobs to specific robots at specific times along a predetermined path) is central to Robot Fleet Management. When dispatched properly, it minimizes idle time, avoids bottlenecks, and helps meet Service Level Agreements (SLAs). In addition, a well-designed fleet management system will support “mixed fleets,” where multiple robot brands/models are operating out of the same location.

Navigation/Traffic Control is another major function of a Robot Fleet Management System. The rules governing how robots pass one another, yield to one another, and reroute around obstacles or when pedestrians occupy common areas must be defined by a fleet management system. This may include establishing a maximum speed limit per lane, defining one-way travel in certain areas, designating “no-go” areas, and dynamically adjusting a robot’s route to minimize traffic congestion in the surrounding area.

By using Robot Fleet Management to track maintenance and monitor robot performance, reliability improves. Battery level, charging schedule, motor temperature, errors, and robot utilization can be tracked by the system. Using this information, a team can shift from fixing problems as they occur to performing preventive maintenance, reducing downtime, and extending hardware lifespan.

Data and reporting enable Robot Fleet Management to translate operational decisions into measurable results. Metrics used to measure performance include: number of tasks completed per hour, average mission time, time spent waiting in queues at pickup and drop-off locations, near-miss alerts, and charge cycle efficiency. Using these metrics enables managers to adjust workflow design, relocate staging areas, and add robots only when throughput improves.

Robot Fleet Management provides an additional layer of security and enables connectivity to WMS, MES, and ERP systems, allowing robots to automatically receive work orders based on their assigned types. Role-based access control, audit logs, and encryption of all communications ensure that no unauthorized users can access operational data or make unsafe changes.

When evaluating potential solutions, look for the following three factors: (1) How does Robot Fleet Management handle peak traffic and failures? (2) How easy is it to integrate Robot Fleet Management with your current software and maps? (3) How does Robot Fleet Management support and enforce safety standards in human-shared operating environments? When done correctly, Robot Fleet Management delivers predictable, scalable, and simple operations every day.

From Chaos to Clockwork: How a Smart System Creates a Team

You used to view a robot as a separate entity — a single, clever machine. Now, you are able to see the entire orchestra of robots. The true genius behind robot fleet management does not lie in a checklist; rather, it lies in a continuous cycle of observing the fleet, directing its activity, optimizing its workflow, maintaining its health, and learning from the data collected. As you run through each of these steps, you create an ever-increasing intelligent process.

The cycle enables the transformation of a group of machines into a single, organized workforce. The largest benefit of centralizing robot control is the ability to transform disparate equipment into a unified, well-coordinated team. Instead of chaos, you will begin to see the hidden intelligence at work, making processes operate like clockwork and unlocking the full potential of collective robot effort.

Robot fleet management is not limited to large-scale mega-factories. The next time you see a delivery robot moving down a sidewalk, a cleaning robot moving throughout a hospital, or a grocery cart being pulled by an automated cart, you will begin to appreciate the “brain” behind the operation. With your new perspective, you will begin to see how this technology is creating an increasingly efficient world, one intelligent fleet at a time.

Robot Fleet Management Software: Centralized software to monitor and control robot fleets.

Robot fleet management systems are central, computer-based systems that enable teams to track, coordinate, and control multiple robots through a common interface, whether autonomous mobile robots in a warehouse, delivery robots in a hospital, or inspection robots in a manufacturing environment. Unlike the traditional approach of having multiple people check on each individual robot, robot fleet management systems provide a single user interface for status, location, task completion, and alerts.

A key function of robot fleet management systems is the automated assignment of jobs to specific robots. Using data such as proximity to the task, remaining battery life, capabilities, and priority, the system will automatically assign the most suitable robot to perform the task, reducing downtime due to waiting for a robot to become available, eliminating duplicate assignments of tasks to multiple robots, and improving throughput when performing tasks at peak levels.

In addition to automated job assignment, some systems include scheduling rules (e.g., assigning the highest-priority task first) and exception handling (e.g., rerouting a robot if a corridor is temporarily blocked by another object).

Real-time supervision, route optimization, and coordination are additional functions provided by typical robot fleet management systems. Route planning, geo-fencing, speed limits, right-of-way protocols, safe stop behaviors, and other forms of traffic coordination can be managed by these systems in multi-robot operating environments. When the operating environment changes, such as due to a closed aisle or a temporary obstruction, the robot fleet management system can dynamically adjust the routing plan to maintain workflow and minimize delays and congestion.

A good Robot Fleet Management Software Platform will improve uptime by monitoring the health of your robot fleet. That means tracking battery trending, charge behavior, fault codes, communication, and usage, which will alert you to issues before they become major. This allows maintenance to shift from repairing failed robots (reactive) to servicing them on schedule (planned), helping extend each robot’s life and reduce unplanned downtime.

Robot Fleet Management Software is important for both data and integration. Using operational analytics (e.g., missions per hour, average travel time, queue time, failure rate) will provide insight into where your bottlenecks lie and what you need to do to improve. Another important consideration is integration with your Warehouse Management System (WMS), Manufacturing Execution System (MES), and Enterprise Resource Planning (ERP) system(s) so your robots receive work orders automatically. Role-based access and audit log capabilities will also help you manage who can edit your map(s), mission(s), and safety parameters.

When you’re looking at Robot Fleet Management Software — consider things like how scalable the software is, whether it will support multiple robot brands/types, whether the software is reliable even if there’s an interruption in the network, and how easy to use/understand the monitoring and reporting features are. In essence, the ideal Robot Fleet Management Software will simplify multi-robot operations, promote safe operating environments around the robots, and enable you to continually optimize robot performance.

The Big Question: What If My Robots Are from Different Brands?

In theory, if you had every single robot in your fleet from one provider — with all the robots able to communicate with one another in a seamless manner — managing the operation would be very easy. However, real-world business challenges mean there may be multiple companies supplying different robots that operate differently, requiring a more complex management approach.

For example, you could have a number of shelf-moving robots supplied by Company A and then need to acquire packing robots provided by Company B. With the acquisition of the additional robots, you will have a large number of different types of robots and therefore a big problem to solve: How will you manage all of them from a single screen? Getting your Apple Watch to work seamlessly with your Google phone is much the same kind of problem. They were not developed to communicate using the same language.

The ability of different types of robots to communicate in the same environment is called “interoperability.” As the robotics industry continues to evolve, many manufacturers offer a wide range of products. Many manufacturers provide proprietary software to control their products, creating “isolated islands” of technology. Thus, without some type of “bridge” connecting the two systems, you will be required to operate each brand’s robots separately on a single platform.

The ability to integrate multiple systems (and brands) into a single platform is one of the most significant differences between average and superior robot fleet management software.

Fortunately, the robotics industry is moving towards resolving this challenge by establishing robotics fleet interoperability standards. For those familiar with technology, this is similar to the development of USB ports for computers — no matter the make of your laptop or mouse, they can communicate because they adhere to the same standard. Whether the robot fleet management platforms are open-source or commercial, developers are increasingly adopting these new standards to build a “robotic universal translator.”

To date, anyone considering this technology has an important question for potential software vendors: “What is your strategy for achieving interoperability?” The end result is a single dashboard to manage a diverse, multi-brand fleet as a single entity.

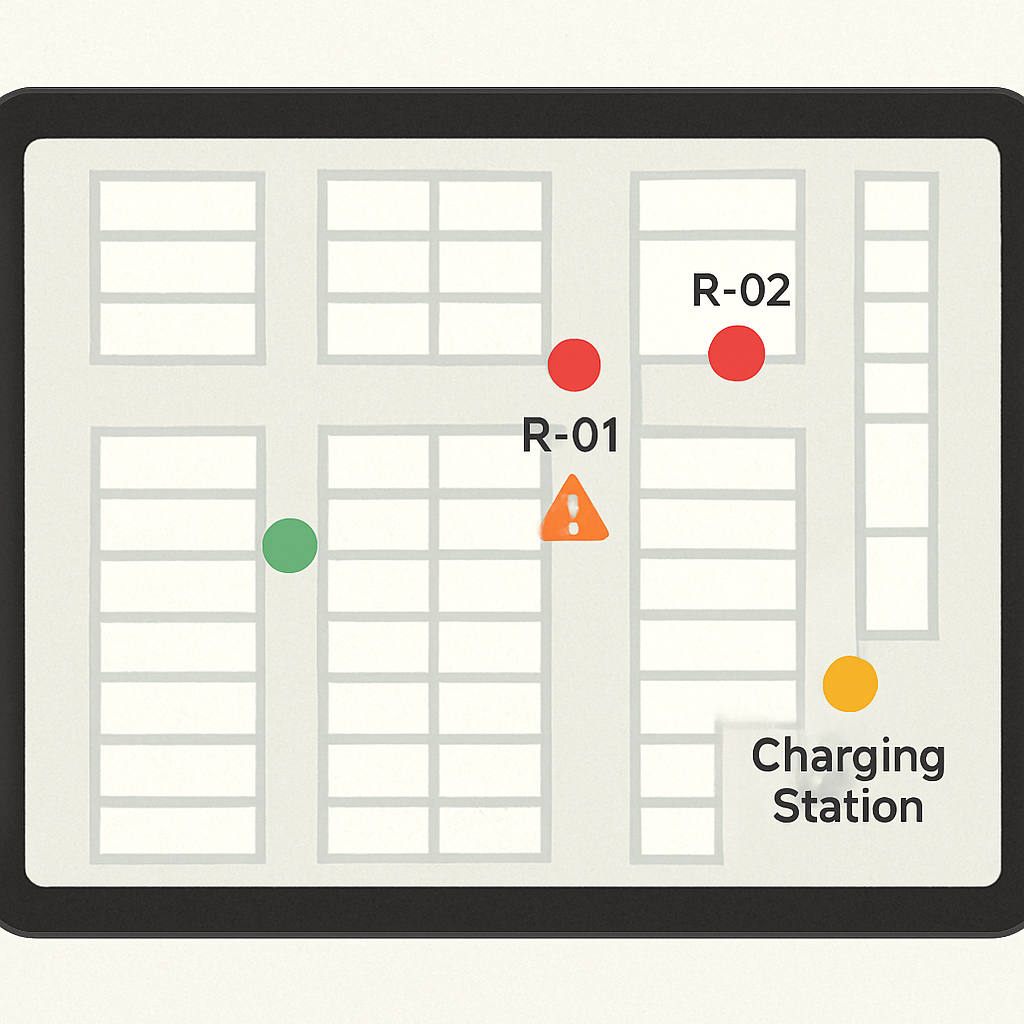

Step 1: Get a Bird’s-Eye View—See Your Entire Fleet on One Screen

Before you can instruct a team of robots, you have to know the location of each robot and its current task or tasks. Total visibility via a centralized dashboard is the first component of managing a robot fleet. This centralized dashboard will provide a visual representation (map) of all robots in your facility, which will create order out of potential chaos and allow you to assess the situation quickly at a glance.

Without a full view of your operations, giving intelligent orders to your robots is virtually impossible. A typical dashboard will display your facility on a map, with each robot’s movement shown as an icon. The dashboard will track your robots’ statuses in real time, providing immediate answers to key questions.

Is Robot-01 currently holding a shelf? If so, Robot-01’s icon may be green and moving. Is Robot-02 running low on battery? If so, Robot-02’s icon will turn yellow and move toward a charging station. Has a robot encountered a problem or obstacle? If so, Robot-01’s icon will turn red, indicating to a human manager that assistance is required.

Total visibility through a dashboard enables you to move from guesswork to actionable insights into the status and health of your robot fleet. With a single view of your robot fleet, you are able to go from being uninformed to having access to actionable information.

Visibility is not just for monitoring your fleet; it is the first step in taking control of your robot fleet. Once you have a view of all your robots and their locations, you are ready to issue instructions to them.

Fleet Tracking Technology: Real-Time Visibility into Robot Locations and Performance

Fleet Tracking Technology provides real-time information on robot location, activity, and performance within operations. In busy warehouses, hospitals, factories, and campus settings, knowing where and what robots are doing allows management to manage rather than guess. Once Fleet Tracking Technology is integrated with your robot fleet management system, managers will be able to see current locations, currently assigned jobs, downtime, and exceptions on a single map-based view.

Essentially, Fleet Tracking Technology captures telemetry (position, speed, battery life, connectivity, job status, error codes, etc.) and converts it into dashboards and alerting systems. For Robot Fleet Management, tracking capabilities enable management to rapidly identify congested areas, blocked paths, missed handoffs at pickup/drop-off stations, or robots that have become “lost” while searching for targets. Additionally, Fleet Tracking Technology enables geofencing, allowing teams to verify that robots comply with designated prohibited zones, one-way aisles, and safe buffers around individuals and equipment.

Another major advantage of Fleet Tracking Technology is the ability to monitor performance. Using Fleet Tracking Technology, organizations can measure the following: utilization per robot, missions completed per hour, average mission travel time, wait times, and charge-cycle efficiency. These metrics answer key operational questions through Robot Fleet Management reviews: Are there sufficient robots, or is the staging area limiting productivity?

Are routes optimized, or are tasks released too early/late? Should speed limits be reduced, or should passing zones be added, and/or should batches of work be modified? Improvements made using Fleet Tracking Technology are supported by objective evidence rather than anecdotal information.

Fleet Tracking Technology helps to enhance both maintenance/reliability and fleet management by trending data from the robot fleet, such as battery health, motor temperatures, faults per hour/week/month, network dropouts and other data points, allowing teams to recognize trends in a specific area of failure prior to a failure occurring and subsequently schedule preventative maintenance to avoid unplanned downtime. Steadier throughput and less disruption of production during peak periods are directly related to Robot Fleet Management through the use of Fleet Tracking Technology.

Lastly, Fleet Tracking Technology will support accountability and integration. The time-stamped logs generated can record the date/time and location of each event, providing a history for investigation and continuous process improvement. If Fleet Tracking Technology is integrated with Robot Fleet Management and higher-level systems (WMS/MES), it provides assurance that tasks are assigned appropriately to the correct resources, robots are utilized effectively, and performance is transparent as the fleet grows.

Step 2: Be the Director—How the System Assigns Work So You Don’t Have To

You’ve now got the ability to view your team on a map, so it’s time to get them working. There is no need to micro-manage every single robot. You are the director, and you will create a higher-level mission, such as “get all the items needed for those 20 online orders”. Your system will know what needs to be accomplished and use its intelligent fleet management capabilities to determine which robot (or robots) will complete the tasks and how (the path they will take).

In this section, we introduce a critical concept: task allocation. Task allocation is similar to using a modern dispatcher for a food delivery company. When you place an order, the system does not send a message to every driver in the city. The system instantly identifies the nearest, and/or available driver and assigns him/her the job. Robot management systems do the same by evaluating which robot can complete a task fastest, taking into account their location, battery life, and current workload.

It is the automation of this process that provides the key to increasing the overall efficiency of a robot fleet. While a human may be able to manage the assignment of tasks to a small number of robots, there is no way to accomplish this with a large number of robots. A smart system can optimize the task allocation for a group of robots in milliseconds and ensure that none of the robots sit idle when a task is ready. It removes the logistical bottlenecks associated with managing a large number of robots and enables your fleet to operate as a highly efficient, coordinated unit.

Your role will shift from firefighter to strategic planner. The system will assign tasks to your robots, and they will move with purpose. However, this purposeful movement presents the next challenge — traffic management.

Fleet Automation: Automate task assignment and robot coordination

Fleet automation is the use of software and business rules to automate work assignment to robots, navigation, and overall facility operation with minimal operator input. With fleet automation, instead of manual methods for assigning jobs to individual robots, the software continually assesses service demand, available robots, and facility operational conditions to provide quick, consistent decisions. Combined with robot fleet management, a group of robots can be turned into a coordinated workforce.

A primary advantage of fleet automation is the ability to assign tasks automatically. It can determine the “best-fit” robot for the task by matching factors such as proximity to the pickup point, battery state of charge, payload capacity, sensor suite, and priority level. As part of robot fleet management, this helps minimize idle time, eliminate duplicate work, and meet service-level agreements during periods of increased task volume. Fleet automation may also enable workload balancing, so that one robot does not become overworked, while others remain unused.

In addition to workload and task assignments, coordination and traffic control are just as important. Fleet automation can manage all aspects of right-of-way rules, dynamic routing, speed limits, and safe stops in shared spaces. For example, if an aisle becomes blocked or a robot fails, fleet automation can reassign tasks and dynamically route nearby robots to prevent congestion. The capabilities provided by fleet automation support the objectives of robot fleet management, including predictable throughput and safe interaction with people, forklifts, and other vehicles.

In addition to optimizing fleet performance, Fleet Automation can aid in planning and managing robot charging resources. For example, the robots can be scheduled to charge at non-peak hours of demand, the robots are able to get to their charger quickly by rotating through them, so there isn’t much wait time in a line, and the robots go back to a staging area, which minimizes “deadhead” travel. The policy for automatically charging robots in Robot Fleet Management is used to keep robots available and prevent unexpected capacity reductions due to drained batteries.

Another benefit of Fleet Automation is operational insight. Fleet Automation provides data on cycle time, queue time, travel distance, successful completion rate of missions, and what caused exceptions. The robot fleet management team can then use this data to adjust dispatch rules, modify the layout, and determine whether adding more robots would increase production or simply increase congestion.

When implementing Fleet Automation successfully, it is recommended that you first focus on clearly defined business rules, handling exceptions safely, and integrating with systems that generate work (such as Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES)). When implemented correctly, Fleet Automation reduces manual coordination, delivers consistent results, and enables Robot Fleet Management to scale from a small pilot to a large-scale, multi-zoned operation.

Step 3: Set the Rules of the Road—How to Prevent Robotic Traffic Jams

Robots performing tasks and navigating a warehouse pose challenges for fleet managers. Problems are likely to arise when robots perform tasks in a warehouse if there isn’t a smart system in place to set the rules. Without a smart system creating rules for robots, your warehouse floor will look like a highway with no traffic lights or speed limits. In this case, you are transitioning from simply assigning tasks to managing the warehouse workflow. What was previously a possible robotic traffic jam becomes a well-choreographed, well-organized dance.

The system’s intelligent component will continue to optimize robot task assignment once digital traffic laws are established. Instead of always using the closest available robot for a job, the system will apply rule-based logic to provide common sense across the entire robot fleet. Examples of the types of rules that can be programmed include:

- Narrow-aisle traffic flows in one direction to prevent robots from colliding head-on.

- Robots assigned to carry time-sensitive (urgent) orders receive priority and have the right-of-way as they would an emergency vehicle.

- Robots with low battery levels must yield to operational robots and terminate their route at a charging station.

By establishing these rules, you’re essentially directing an orchestra. Every machine now knows its specific task as well as how to act with regard to other machines performing similar tasks. Coordination through automation is a key element in increasing efficiency across robot fleets while minimizing disruptions that delay the movement of goods and machines. However, movement efficiency also relies on the mechanical condition of the machines.

Fleet Optimization: Optimize routes, workloads, and robot utilization

Optimizing a fleet means maximizing the effectiveness of each robot and its operations at every minute while maintaining safety and predictable movement. A well-integrated approach to Fleet Optimization is to embed it within the Robot Fleet Management System, which provides visibility into all aspects of demand, traffic, robot health, and other constraints within a single framework. The objective of Fleet Optimization is straightforward: optimize routes to reduce waiting times and increase average utilization without increasing risk.

To start, fleet optimization will focus on improving routing efficiency. To that end, Fleet Optimization reviews routes that robots take, how many stops robots make along their routes, and identifies areas of congestion along those routes. By updating maps, establishing one-way lanes and speed zones, and creating designated staging locations for robots, the Robot Fleet Management System will reduce “deadhead” miles (traveling without a payload) and total mission time. Dynamic rerouting of robots can help avoid congested or closed aisles or intersections, preventing robots from becoming stuck in queues.

The second area of opportunity is workload balancing. Fleet Optimization will ensure that tasks are assigned to robots based on proximity, capabilities, remaining battery life, and existing commitments. The dispatcher within the Robot Fleet Management System will prevent an overworked robot from receiving additional assignments while underutilized robots remain idle. Fleet Optimization can also batch tasks intelligently (e.g., by grouping near drop-off locations). This helps to eliminate multiple trips between locations and the need for handoffs between robots.

Utilization is not simply “time spent operating” – it is productive time. Fleet Optimization utilizes mission performance information (e.g., missions/hour, average time to complete a pick/drop, time waiting at each station, exceptions/mission, etc.) to determine if throughput is less than what would be expected due to reasons such as robot speed/payload, or navigation behaviors when using a mix of robots in the same fleet.

Once the cause of lower-than-expected throughput is identified, Robot Fleet Management can adjust task priorities for individual robots, adjust release times from upstream systems, or modify station designs to reduce dwell time. The value of Fleet Optimization increases when used with fleets that include a mix of robots, since the robots typically operate at different speeds, carry different payloads, and/or navigate differently.

Another hidden factor that affects productivity is the charging strategy. Fleet Optimization controls when robots are charged so they rotate through charging cycles seamlessly, preventing chargers from creating bottlenecks and keeping total available capacity from decreasing significantly during periods of high demand. Using Robot Fleet Management, the robots can charge opportunistically, schedule charging slots, and avoid traveling great distances solely to charge.

Finally, continuous improvement ensures that the results achieved by utilizing Fleet Optimization do not drift over time. Fleet Optimization should be reviewed regularly (weekly/monthly) and specific KPIs established to measure success, and the Robot Fleet Management policy settings should be adjusted based upon evidence of effectiveness. Ultimately, Fleet Optimization transforms routing, workload, and utilization into an automated, scalable system that scales with your fleet.

Step 4: Keep Your Fleet Healthy—Automating Charging and Maintenance

Even with the best possible design, all robots will need to be charged at some point in their lifetimes. An uncharged robot in a high-traffic area will likely cause operational delays. With a smart fleet management system, recharging becomes fully automated and runs in the background. The system monitors each robot’s available power and sends it to a charging station during idle periods or when a task is completed. Smart fleet management ensures the entire fleet operates at maximum efficiency, minimizing the need for human intervention.

A smart fleet management system does more than just ensure proper battery health for the robots in the fleet. As physical components on a robot begin to break down, predictive maintenance for a robotic fleet is where those systems come into play. A “check engine” light on your vehicle tells you that there was a problem with your vehicle before you had a chance to see it yourself. Predictive maintenance is even better than a “check engine” light; it’s as if your vehicle told you, “I’ve been tracking my performance data, and I think I’ll need service on my transmission next month.” Predictive maintenance is about fixing problems before they happen.

Predictive maintenance would not be possible without continuous monitoring and diagnostic technology in the robot fleet. By integrating Internet of Things (IoT) into robot management, sensors installed on each robot monitor subtle performance changes—such as a motor running hotter than normal, a wheel vibrating slightly differently than usual, or a battery taking longer than expected to recharge. The system learns normal behavior and flags small deviations in the robot’s performance, prompting a technician to conduct a pre-failure inspection to prevent a major operational delay.

The ultimate goals of both automated recharging and predictive maintenance are to prevent costly operational delays caused by a robot malfunction. A robot that needs a brief examination is a minor inconvenience; a robot that breaks down in the middle of a critical pathway is a disaster. Proactively maintaining fleet health increases reliability while saving significant time and money. All monitoring produces a wealth of valuable information, which serves as the basis for the final stage: analysis.

Mobile Robot Fleet Management: Coordinate autonomous mobile robots efficiently at scale

Mobile Robot Fleet Management is both an emerging discipline and a software layer for coordinating autonomous mobile robots (AMRs) and ensuring their safe and efficient interaction within a facility. As the number of mobile robots increases from a few to tens or even hundreds, Mobile Robot Fleet Management will become increasingly important for organizing jobs, ensuring clear paths, and improving the predictability of robot performance. In practice, Mobile Robot Fleet Management is a special case of Robot Fleet Management, specifically focused on mobile robots used to transport items, parts, supplies, or equipment between points.

One of the primary functions of Mobile Robot Fleet Management is dispatching. Based on factors such as distance, current load, capabilities, and available charge, Mobile Robot Fleet Management determines which AMR should take each task to ensure no robot is idle and no two robots have the same assignment. The most effective method for increasing throughput in Robot Fleet Management systems is typically to apply intelligent dispatching rules.

Another key area is traffic coordination. Mobile Robot Fleet Management will define how robots interact with one another in shared hallways, intersections, elevators, and work cells. Mobile Robot Fleet Management can enforce right-of-way rules, speed zones, and geofence boundaries, and dynamically redirect robots if an aisle is blocked or if people are in the path of an intersecting robot. These traffic coordination functions support Robot Fleet Management objectives by minimizing bottlenecks and improving safety for humans, robots, carts, and forklifts in mixed-use environments.

Mobile Robot Fleet Management allows operators to see, in real time, the location of robots, mission status, how long each robot has been waiting to enter the next station (queue), and any exceptions from a single centralized screen. In Mobile Robot Fleet Management, real-time visibility reduces “chase time” for robot issues and accelerates response times when a robot gets stuck, experiences disconnections, or requires assistance.

To operate at scale, Mobile Robot Fleet Management will need to manage the charging and uptime of all robots in the fleet. The application can schedule rotation charging, prevent congestion at chargers, and track health signals, including battery degradation, fault codes, and loss of connection. As a result, the team using the Robot Fleet Management application can transition from reactive troubleshooting to proactive scheduled maintenance and continuous improvement.

The last component is integration. Mobile Robot Fleet Management typically integrates with WMS, MES, or hospital logistics systems to enable automatic task creation and priority assignment. If done properly, Robot Fleet Management becomes an end-to-end workflow engine; upstream systems initiate work, the fleet system assigns it, and performance information feeds back into the planning process.

Therefore, Mobile Robot Fleet Management enables AMRs to function as a scalable, coordinated fleet—easier to measure and improve over time—and as part of a larger Robot Fleet Management strategy.

Step 5: Become a Data Detective—Using Analytics to Make Your Fleet Smarter

All that monitoring does much more than prevent equipment failures – it creates an enormous amount of knowledge. Each activity, each path, and every charging event becomes a data element. That’s where robot fleet data analysis comes in, converting those numbers into meaningful insights. The management software acts as an investigator, continuously monitoring your operations to identify clues that help you run them more efficiently. Management software can answer many questions for you, such as “Is one of my robots more efficient than another?” or “At what time of day do I have the greatest number of bottlenecks?”

The best way to use this information is when it is presented clearly. Rather than requiring you to review countless spreadsheets, the software can provide the data in a visual format. One of the best ways to visualize data is with a performance heat map. A performance heat map is similar to a weather map of your warehouse floor, but instead of showing rain, clouds, and sunshine, it shows levels of robot activity using color scales.

The heat map helps identify “hot spots” (where robots get stuck) and “cold spots” (underutilized areas). With this visual evidence of inefficiency, you can immediately improve your robot fleet’s operational efficiency by adjusting individual robot routes and/or reconfiguring specific areas of operation.

In addition to improving fleet efficiency, the data provides confidence to develop a solid, fact-based business strategy. When you can prove with data that your current fleet of autonomous robots is operating at approximately 95% of its potential, the discussion regarding increasing the number of robots as the demand grows shifts from speculation to fact-based reasoning. As a result, you will be able to provide factual justification to expand the deployment of autonomous robots to meet increased demands on your operations.

The five-step process described above illustrates how a unified fleet of autonomous robots can benefit a business. The next logical question is: What happens if the autonomous robots that comprise your fleet are not all from the same “family”?

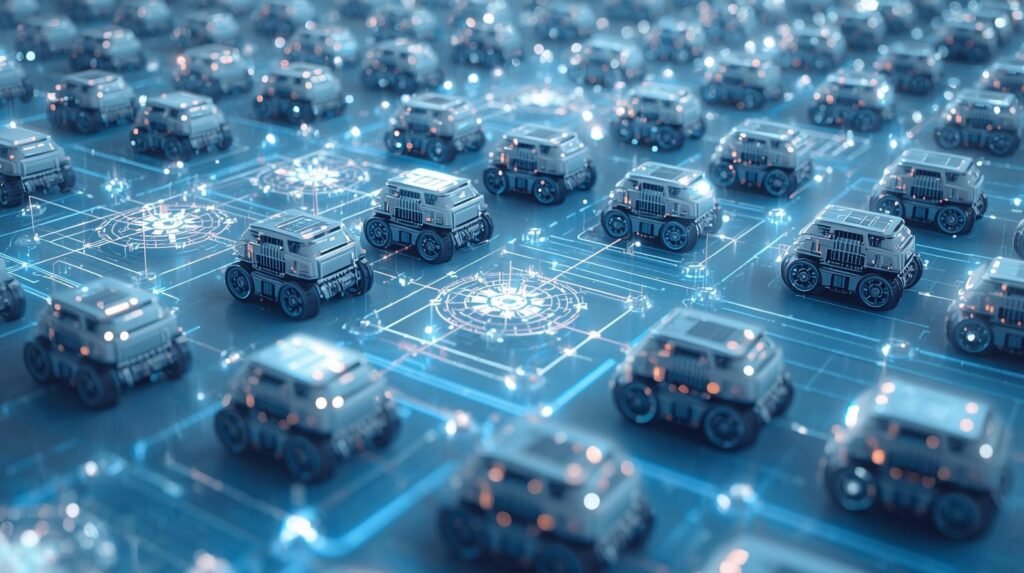

Autonomous Robot Fleet: Self-coordinating robots working together intelligently

An Autonomous Robot Fleet is a collection of individual robots that can navigate and make local decisions while operating in a coordinated manner with little to no direct human supervision. While the benefit of an Autonomous Robot Fleet is not merely that each robot is individually “smart,” it lies in the group’s ability to coordinate task completion, avoid conflicts, and maintain operation under changing conditions.

In almost all realistic environments, some form of coordination will require a control layer to function effectively. A key element of Robot Fleet Management is providing common rules and visibility to enable the collective functioning of an Autonomous Robot Fleet as a single system. Using the same real-time data sources, such as distance from a given task, payload capacity, the current workload, and battery life, Robot Fleet Management can assign tasks to the appropriate member of the Autonomous Robot Fleet in order to minimize idle time, eliminate duplicate assignments, and rapidly respond to high-priority tasks.

Safe operation by a large number of robots at scale is also a defining requirement. An Autonomous Robot Fleet must be able to safely navigate through intersections, narrow corridors, shared hallways, and mixed traffic, including people, forklifts, etc. Robot Fleet Management enables the safe movement of a large number of robots by establishing and enforcing traffic policies (such as right-of-way, speed limits, one-way zones) and using geofences to define restricted areas and dynamically reroute around obstacles. If a path is obstructed, an Autonomous Robot

A well-organized Autonomous Robot Fleet has the ability to adapt by shifting task distribution among the robots, pausing them, and redirecting flow to ensure that the system remains in motion (as opposed to being static).

Monitoring is essential to ensure reliability and enable the timely detection of issues within the Autonomous Robot Fleet. Data generated by each robot on its state and any faults encountered will be used by the Robot Fleet Manager to generate alerts and trends, enabling the team to identify potential problems before they occur and plan and schedule necessary maintenance. It also enables answering many practical questions, such as where the most congestion occurs. Where does the first sign of congestion begin? What behaviors are exhibited by the robots that result in reduced throughput?

Integrating the autonomous fleet with other systems, such as Warehouse Management Systems (WMS), Manufacturing Execution Systems (MES), and Service Ticket Tools, enables the automatic generation and consistent prioritization of tasks. Once integrated, the Robot Fleet Management System serves as the execution layer, receiving and scheduling work for the robots and reporting their performance to the planners and operators.

An Autonomous Robot Fleet will succeed as long as there is predictability of coordination, enforcement of safety, and measurability of performance. With proper processes, analytics, and governance, an Autonomous Robot Fleet can scale from a pilot deployment to facility-wide automation without turning everyday operations into constant problem-solving.

Conclusion

When managing multiple devices as a single entity to consistently deliver reliable results, this is called “robot fleet management.” The five steps outlined in this article to assist with creating a reliable robot fleet — visibility, smart task assignment, digital traffic laws, automated charging and maintenance, and using data to improve — will enable you to manage your robots on a daily basis more easily, safely, and efficiently than would be possible through manual coordination.

The largest transition is from tactical (reacting to stuck robots, low batteries, and traffic) to strategic (preventing problems by design). A central dashboard provides you with the information you need to determine how things are going at all times. Smart dispatches enable continuous robot productivity with minimal supervision. Digital “traffic” rules enable smoother robot movement. Predictive maintenance and battery charging policies protect up-time. Finally, analysis of routine robot use enables you to make informed decisions about route optimization, layout, and personnel allocation.

Interoperability, when expanding your fleet or adding different types of robots to your fleet, will become as critical as performance. Tools that can operate across multiple vendors and integrate each vendor’s robots into a single control layer will support long-term investments. If done correctly, robot fleet management does not merely diminish chaos — it creates consistent, clockwork dependability that supports growth.

FAQs

- What is robot fleet management (RFM)?

The use of centralized processes and software to manage multiple robots within a single system has enabled “fleet management” of robots. - Why can’t I manage a fleet by controlling robots one by one?

Robot fleets require more than manual, robot-by-robot control because such control does not scale with the number of robots. Manual control can create duplicate tasks, cause traffic jams among robots, lead to unnecessary downtime due to improper charging methods, and result in slower response times when a robot encounters an obstacle or faults. - How does the system decide which robot gets which task?

Fleet management software automates task allocation. This means the best robot for each task is selected based on factors such as its current position, workload, capabilities, priority level, and battery state. - How do fleet systems prevent robotic traffic jams and safety issues?

Fleet management also includes rules similar to those found in “roads”, such as one-way traffic, right-of-way priorities, speed limits, geofences (i.e., digital barriers), and dynamic rerouting if pathways become obstructed or congested. - Can one platform manage robots from different brands? When robots are from different vendors, fleet management software can integrate them into a single dashboard and workflow via interoperability, either through standardization or integration. When evaluating fleet management products, it would be helpful to understand how they enable you to integrate your multi-vendor robots into a single dashboard and workflow.