Picture a factory robot. Most likely, you picture a large, powerful robotic arm quickly moving around heavy parts and protected by a very large protective cage. That is basically how automation has been implemented for many years. While these systems have been highly effective and productive, the distance required to protect people from injury has made them extremely difficult for people to approach.

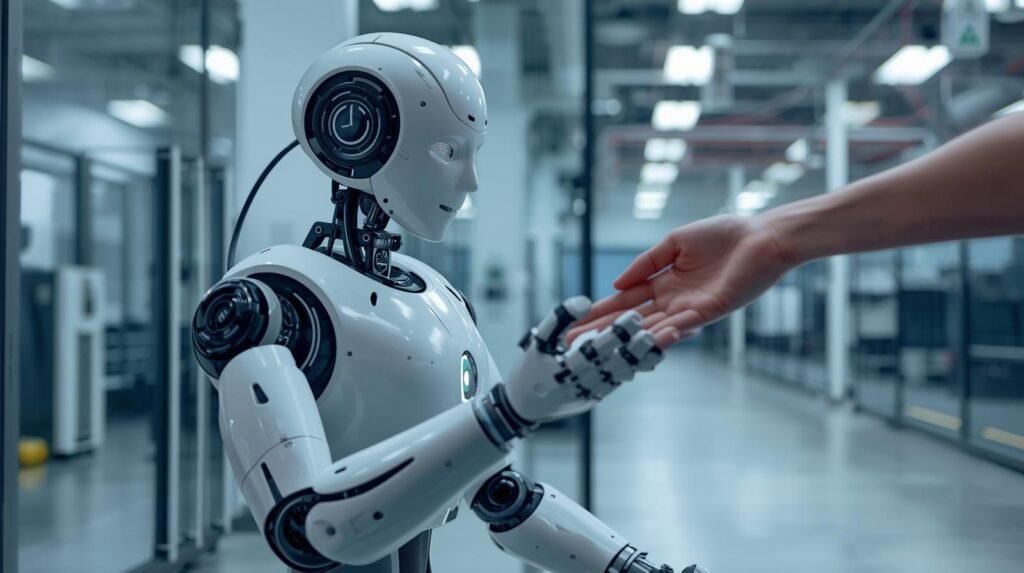

What if there were a type of machine where a robot could be a safe, helpful partner working alongside a human? This is the essence of a new class of machines called Collaborative Robots (Cobots). Cobots are designed to safely collaborate with humans. They are often lightweight and equipped with advanced sensors that quickly detect when something unexpected comes into contact with the robot, such as a person’s hand/arm.

A cobot is most likely to be thought of as a tireless, super-powered helper. A cobot excels at performing repetitive, boring, or physically demanding portions of a task, while allowing its human partner to handle tasks that require agility, critical thinking, and problem-solving. Cobots’ ability to easily learn new tasks makes them true collaborative partners, not simply one-time-use appliances like a robot vacuum cleaner.

Summary

Cobots (collaborative robots) are designed to work alongside humans rather than being confined to areas without people. In this way, they provide the reliability and accuracy of an automated system to a shared workspace through a set of safety-oriented features. These include: controlled speed and/or force, contact detection, and stop monitoring. Cobots can also increase worker productivity while allowing human coworkers to make final quality decisions and handle exceptions.

In manufacturing and logistics, cobots have been widely adopted for tasks such as assembly assistance, packaging, machine tending, and inspection. One of the most significant advantages of cobots over traditional industrial robots is their adaptability to different environments. Many cobots require less programming, can be easily redeployed, and are well-suited for environments where products or processes vary greatly (i.e., high-mix).

The successful implementation of a cobot begins with identifying the best task(s) to automate, completing a risk assessment, and designing the workstation to promote safe human-robot collaboration through proper tools and operator training.

Ultimately, cobots enable teams to eliminate repetitive motions, improve output stability, and enhance product quality without eliminating human involvement. When combined, human decision-making and robotic repetition create powerful, friendly “partners” that contribute to safer, more productive, and more flexible workplaces.

Collaborative Robots: Robots designed to safely work side by side with humans

Collaborative Robots are designed to coexist with humans in the same workspace. These Cobots do not require the heavy enclosures that many traditional automated systems require to protect workers. The design of Collaborative Robots encourages them to work together with humans as an extension of the worker’s hands, providing consistent precision, motion, and speed while the human provides judgment, dexterity, and problem-solving skills.

Unlike most Industrial Robots, Collaborative Robots (Cobots) have limited force, speed, and awareness and can be easily programmed to stop, slow, or pause operations when a human is nearby. As Cobots will be working in shared spaces, they are designed with safety in mind, featuring rounded edges, reduced power, and sensors.

Most Collaborative Robots include safety-rated features such as force/torque monitoring, speed/separation checks, and emergency stop functions. When unexpected contact occurs, Collaborative Robots will “feel” it and respond accordingly, limiting the potential of injury and damage to the product. Collaborative Robots utilize intelligent programming, vision systems, and thorough risk assessments to develop a plan for each task, tool, and environment.

Collaborative Robots are at their best when combined with the correct end effectors, well-defined operating procedures, and trained workers.

The most common applications of Collaborative Robots on factory floors include machine tending, light assembly, screwdriving, labeling, inspections, and packaging. These jobs are repetitive and therefore cause worker fatigue; human involvement is still needed to provide contextual oversight. Collaborative Robots can also be deployed in warehouse environments to support kitting, pick-and-place, and scanning workflows, enabling warehouse employees to meet growing demands.

Collaborative robots have been deployed in laboratory environments for sample handling and routine instrument loading to reduce technician error and free technicians from lower-value tasks, such as manual instrument loading, enabling them to focus on higher-value analytical tasks. Collaborative Robots (Cobots) are being adopted by small companies for their ability to be quickly implemented, easily reconfigured, and operated flexibly compared to traditional automated cells.

To successfully deploy Collaborative Robots, you must identify the right application, verify safety parameters, and evaluate ROI by increasing throughput, improving quality, and reducing rework. As Collaborative Robots improve their sensing capabilities, ease of programming, and integration with existing systems, they will become increasingly reliable team members, boosting productivity while preserving human decision-making authority in areas that require contextual judgment and care.

Human-Robot Interaction: Cobots are designed to interact safely and intuitively with human workers

Human-Robot Interaction is a key component of creating a collaborative experience between humans and robots. Cobots are built with both safety and intuitive interaction for human workers, allowing a shift from “stay away from the robot” to “use the robot as an asset.” With good Human-Robot Interaction, all aspects of the robot’s movement, signaling, and actions become predictable and consistently understood by all users throughout their tasks, reducing confusion and building confidence on the shop floor.

An important element of Human-Robot Interaction is communication. Cobots provide visual cues (status lights, screen prompts, path indicators) and basic physical cues to help operators direct the robot in performing tasks without requiring programming or code. Cobots can also guide hand motion, quickly reteach specific points, and offer simple task-selection options to help inexperienced users build confidence with cobots more quickly. Additionally, Human-Robot Interaction involves the “feel” of the team effort—Smooth transitions into and out of operation, slow speed when operating in proximity to people, and purposeful movements at a pace that mirrors the natural flow of human labor.

Safety and usability converge in Human-Robot Interaction when a system is developed using real-world workflow processes. In addition to typical features such as force limiting, emergency stops, and sensors used to detect and prevent harm from occurring by way of unwanted contact, an important factor in achieving intuitive collaboration between humans and cobots lies with the design of the work cells; specifically how clearly defined are shared workspace areas, which end-effectors have been chosen, and how straightforwardly are procedures explained.

The more successful the design of a Human-Robot Interaction system is, the less time employees will need to devote to “babysitting” their automated workstations, and the more time they will have for decision-making, including monitoring product quality, managing product variations, and improving their overall processes. Cobots may then assume responsibility for routine production tasks (e.g., part positioning, fastening operations, and part loading), allowing employees to focus on higher-value-added activities (e.g., making quality judgments).

The success of Human-Robot Interaction evolves over time through user feedback and iterative refinement. As teams identify confusion or delays, team members begin modifying robot operation parameters, such as speed, approach path, and prompting language. Additionally, teams develop new training for users that emphasizes clarity. Successful implementation of cobots occurs when these systems are perceived as reliable partners in the workplace—responsive, transparent, and respectful of each employee’s personal space — thereby facilitating safe, comfortable, and ongoing collaboration throughout each work shift.

Cobot Safety: Cobot safety features allow humans and robots to share the same workspace

Cobots are designed for collaborative environments, enabling machines and workers to work in close proximity while remaining safe. Cobot Safety aims to enhance practicality by controlling and minimizing risks associated with shared workspaces through design, sensing technology, and strict operational guidelines. Rather than simply creating fenced-in areas around robots, many work cells are developing “smart” systems to ensure both productivity and safety are maintained within those areas while the robot performs its intended function.

A major element of Cobot Safety is establishing the maximum physical force and speed at which a robot may approach a person at any given time. There are several ways to accomplish this, including power-and-force limiting (i.e., the system detects unexpected contact and immediately stops) and speed-and-separation monitoring (where the robot reduces speed as it approaches a person). A third method is called a safety-rated monitored stop (in which a worker enters a designated area; the robot pauses movement until a safe condition exists, then resumes).

These methods enable Cobots to perform repetitive tasks while maintaining a buffer or safety envelope that allows a worker to be near the Cobot.

Another factor to consider in the safety of good cobot design is tooling and layout. Even though an inherently safe robotic arm is safer than others, sharp-edged end effectors, pinch points, and/or unstable parts can still pose hazards. Therefore, many companies choose to use cobots with round-grip grippers, guard their tools, support their parts, and position their fixtures to eliminate hazards.

Risk assessment is a necessary element of safety design. Teams assess the part’s geometric dimensions, speed requirements, potential contact areas, and operator movement patterns, and establish safety limits and functions accordingly. A properly validated safety system makes Cobot safety measurable rather than merely a statement.

The final element that enhances Cobot safety through a human-centered approach is visual indicators of the cobot’s task state (e.g., speed, stop), easily accessible emergency stops, training, and a defined procedure for task handoff between operators. When operators know what the cobot will do and when it will slow down, stop, or remain stationary, collaboration is much more predictable. In reality, the safest deployments view cobots as team members that operate within established and tested parameters. This allows both humans and cobots to work together safely and efficiently in a shared workspace.

Cobot Applications: Cobots are widely used for assembly, packaging, and inspection tasks

Cobot applications have changed how manufacturing and warehouse environments handle repetitive work by enabling a collaborative relationship between flexible automation and human oversight. Since Cobots were designed to coexist with humans in their workspaces, Cobot applications can typically be integrated into existing lines with little or no redesign. As a result, practical automation is being developed to enhance process reliability while enabling workers to continue focusing on judgmental steps (e.g., problem-solving, changeovers) that robots cannot perform.

In assembly, Cobot applications are most often used for tasks including: screw driving, press fitting, dispensing, inserting connectors, and completing light sub-assemblies. Cobots are ideal for repetitive applications where product variation is frequent, since they can be easily retrained and redeployed from station to station. Many Cobot applications leverage the robot’s ability to repeat motions, using fixturing and sensors to confirm position, torque, and/or part presence, reducing rework. By sharing the workload with both humans and Cobots, workers can focus on complex alignments and final checks, while the robot handles repetitive, fatiguing motions.

Packaging is another area where Cobot Applications deliver rapid return on investment. Cobots can pick and place items within containers, apply labels, fold boxes, and perform end-of-line packing tasks. Cobot Applications are particularly beneficial during periods of frequent product changes and/or increased production demands that require rapid scaling. By handling the most repetitive aspects of packaging, Cobots will help maintain a stable throughput and reduce the risk of repetitive-motion injuries, while allowing humans to handle exceptions such as damaged packaging, order discrepancies, or custom inserts.

During inspection and testing, Cobot Applications generally include holding a camera to capture images, moving objects through measuring points (using mechanical or optical means), reading barcodes, and placing objects beneath sensors. Cobots’ ability to maintain consistent viewpoints and cycle timing can enhance the reliability of defect detection and traceability.

In addition, many Cobot Applications use vision and/or force feedback systems to enable Cobots to accommodate minor variances while maintaining rigid quality standards. Overall, Cobots will excel in the areas of: (1) dependable throughput, (2) quick changeovers, and (3) collaborative work environments—thus making Cobot Applications a very viable solution for assembly, packaging, and inspection in numerous industries.

Industrial Cobots: Industrial cobots boost productivity without replacing human workers

Industrial cobots enable higher production without removing people from the process. Industrial Cobots do not replace entire lines of automated robots; instead, they take over the most repetitive, precise, or ergonomically stressful parts of a job. By doing so, human workers can focus on tasks that require human judgment, such as problem-solving, quality-related decision-making, and changing out materials or tooling. This is how Industrial Cobots are viewed: as productively improving manufacturing efficiency—not as replacements for employees.

Typical uses of Industrial Cobots in factories include machine tending, screw driving, material dispensing, small part assembly using presses (light press fitting), and assistance in packaging after final inspection. One of the biggest advantages of Industrial Cobots is their ability to be reprogrammed and moved to different stations more quickly and more easily than traditional stationary automation machines.

This makes them ideal for high-mix operations with frequent changes to products, batches, or priorities. When demand spikes, Industrial Cobots can help a team meet it by maintaining stable cycle times and reducing bottlenecks, particularly for tasks that cause worker fatigue over long periods.

Industrial Cobots help increase productivity by enabling consistent results. Humans are good at adapting to different situations; however, repetition can lead to small errors over time. Consistency enables Industrial Cobots to execute the same motion repeatedly and deliver consistent performance, helping limit rework and scrap.

At the same time, there will always be an element of human involvement in tasks that involve interpretation (such as determining whether an item has a cosmetic defect or is fragile) or require responding to unknowns. Workflows designed to leverage Industrial Cobots will have workers perform adaptive work, while the cobot handles the “dull” work.

By conducting risk assessments, designing smart cells, and providing training, Industrial Cobots can help make your operation safer and more environmentally friendly. Reducing heavy lifting, reaching into difficult areas, and repetitive motion can help reduce employee fatigue and, in turn, retain skilled employees. Because of this, Industrial Cobots can often be implemented in stages—automating one function at a time—allowing you to improve production output without shutting down your existing processes.

Overall, Industrial Cobots enhance productivity by strengthening the team through added reliable capacity, increased consistency, and freeing human resources to use their talents to the fullest. As long as you have specific goals and select the appropriate type of Industrial Cobot for your needs, they will serve as a practical means to expand production output while maintaining the integrity of human expertise.

Cobots vs Industrial Robots: Cobots differ from traditional robots by prioritizing flexibility and safety.

The differences outlined in Cobots vs Industrial Robots provide an important basis for comparison when evaluating automation options for your shop-floor workflow. For years, traditional automation has emphasized speed, reach, and repeatability in industrial robots; however, these robots are often housed in fenced cells or other enclosures to protect humans from potential hazards.

As Cobots vs Industrial Robots illustrates, collaborative robots (cobots) have a different focus: they are designed to operate in close proximity to human workers, emphasizing controlled motion, sensors, and safe-by-design interaction with workers.

Additionally, Cobots vs. Industrial Robots discusses how safety is achieved and maintained in each system type. Safety in many traditional industrial robotic applications is typically achieved through physical barriers (such as fencing), light curtains, and strict separation of the robot and human worker; these methods are used because traditional robots can be very fast and carry large payloads.

In contrast, safety in cobot-based systems is achieved through features such as force limiting, monitored stop capabilities, and reduced speeds near the worker, all of which are fundamental to the collaborative robotics philosophy. Therefore, Cobots vs Industrial Robots is much more than simply comparing two types of hardware – it involves the risk assessment associated with the system, the type of end-of-arm tool that will be used, and the arrangement of tasks to allow both the human worker and the automation to coexist in a shared workspace safely and effectively.

The differences between cobots vs industrial robots have never been as evident as they are with flexibility and changeover time. Industrial robots will always thrive in high-volume lines where the process has been perfected and the cell optimized for the highest possible throughput. Collaborative systems are typically easier to move from station to station and to configure for new product lines. In this way, cobots vs. industrial robots represent a significant differentiator in the longer-term integration of a system versus a faster, incremental approach that makes improvements one at a time.

Ultimately, the choice between cobots and industrial robots depends on the job’s requirements: payload, cycle time, precision, environment, and how often the process changes. If you require extremely fast cycles, extreme reach, or heavy payloads, traditional industrial robots are likely your best option. However, if you require easy redeployment, simple task sharing, and/or want to be closer to your operator(s), collaborative solutions are likely going to provide greater overall value. The debate of cobots vs industrial robots is less about competition and more about finding the right automation solution to perform the required work.

Cobots vs. Industrial Robots: What’s the Real Difference?

Industrial robots and collaborative robots (cobots) have vastly differing design priorities. Traditional industrial robots were developed primarily to maximize performance and efficiency (speed) and, as a result, are unsafe for people to be near; therefore, they must be placed inside safety cages.

In other words, there is a clear “trade-off” that exists between high-performance capability and flexibility of operation in terms of collaboration with humans:

- Traditional Industrial Robots: Designed to perform at high speeds, typically in an enclosed cage for safety, and require a highly skilled engineer to program.

- Collaborative Robots (Cobots): Designed to prioritize the safety of both themselves and those around them, cobots will work without being caged while working beside or even with people, and allow anyone to easily train/teach them.

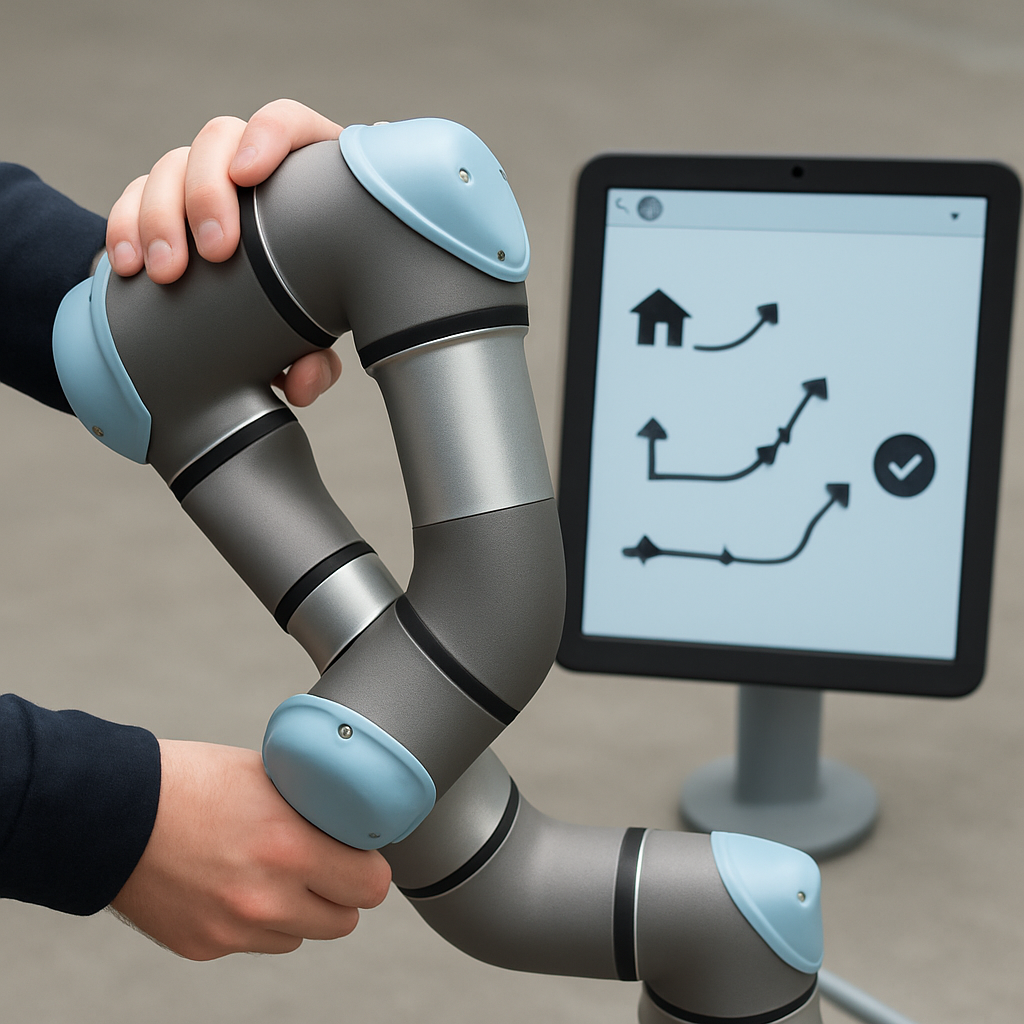

One of the most significant shifts has been in how you instruct a robot to act. Teaching an industrial robot is a complex process that requires an engineer to write code that instructs the robot on what to do. On the other hand, teaching some cobots is straightforward. Typically, all you need to do is pick up the robot’s arm and guide it through the motion you want the robot to repeat. The cobot stores the path it took and will reuse it to complete the same tasks. It is essentially as simple to train a cobot as to train a human apprentice.

How Can You Safely Work Next to a Powerful Robot Arm?

The obvious question when considering working “side by side” with a robot arm is: What prevents it from accidentally injuring a worker? Industrial robots have long been kept separate due to safety concerns, but cobots were developed from the ground up to work safely alongside humans.

The solution is a technology known as force-limiting sensors. Force-limiting sensors are integrated into the cobot’s joints, providing it with a “sensory feel”. While the cobot is operating, the sensors continuously monitor for unexpected forces or friction. Once the sensor determines that the cobot has encountered an object (person) that was not expected (i.e., misplaced parts or a person reaching out and touching the cobot), the cobot will immediately register the contact and stop moving.

Think about an elevator. When you reach out and place your hand in front of the door as it is closing, it doesn’t automatically try to push past your hand; it detects an obstruction and opens the door again. Cobots also operate on this principle. When the cobot strikes something (an obstacle), it immediately ceases all motion within a split second, thereby protecting the potential victim.

This inherent awareness enables cobots to operate without the large, heavy enclosures typically required to protect workers from industrial robots. This means that instead of separating humans and robots, cobots provide a collaborative workspace where people and machines work together safely in the same space.

What Kind of Jobs Do Cobots Actually Do?

So they’re not making whole vehicles and performing brain surgery with their friendliness; so what do these nice robots do? Usually, the answer is found in something very basic and repetitive, which is often tedious, clumsy, or taxing for an individual worker. These robots perform best in jobs that require consistency and endurance, but not problem-solving or creativity.

A common use is the “pick and place” application. A cobot arm will be placed by a conveyor belt. It will pick up a completed product (such as a bottle of sauce or a smartphone) and accurately place it into its packaging, then repeat this process. A human worker will have no distractions or fatigue from the robot, allowing them to inspect the product for quality or begin preparing the next batch.

While simply placing products, cobots can also serve as useful assistants. In the process of “machine tending”, a cobot may load raw material into a machine and remove the completed components, a task that is monotonous and potentially hazardous to workers. Collaborative assembly enables a cobot to act as a third hand, holding a heavy or hard-to-hold part steady while a human performs the detailed task of attaching screws or connecting wires, reducing physical labor.

These are all examples of the same type of activity. The robot handles the dull, repetitive, and physically demanding portions of the task, allowing the human worker to focus on the skilled, judgmental, and adaptable aspects.

Why Would a Small Business Invest in a Cobot?

In addition to speed, another benefit of using cobots is protecting individuals. Think about a job where you have to twist your arm to tighten a piece and lift a twenty-pound box every minute for eight hours. That kind of repeated motion could cause you serious strain and possible injury. When you hand that physically demanding task off to a cobot, you can greatly reduce the number of accidents in the workplace and keep your most valuable employees healthy and happy at work.

That type of consistency also has a significant impact on the overall quality of the products. No matter how skilled a person may be, they will never perform the same task with the same level of accuracy as a machine — they will always use a slight variation in the application of the glue and may apply slightly more or less pressure when tightening a screw. A cobot, on the other hand, will perform a task with robotic precision, applying the same amount of glue (and/or tightening the screws) exactly the same way on the first attempt and the 1000th attempt. This translates into fewer errors, less material waste, and ultimately a better product for the consumer.

These advantages are why cobots represent a great investment opportunity, particularly for smaller businesses. They enable local shops and small factories to compete with large corporations by providing a safe work environment and ensuring the production of high-quality products.

How Do You “Teach” a Cobot What to Do?

Robot programmers would typically picture the process of developing a cobot’s program as a complex computer screen with numerous lines of code. However, in practice, developing a cobot’s programming can be quite surprising, both in its physicality and its intuitiveness.

Many cobots require no keyboard input and are instead developed using a method known as “hand-guiding.” In this method, an operator simply presses a button to allow the arm of the cobot to become loose, and then physically moves the arm around the exact motion of performing a task. After the operator has physically moved the cobot through the motion of the task, the cobot will remember this motion, much like a student learns to trace a shape by having their hand traced over the shape by a teacher.

After the operator has physically shown the cobot the path they want it to follow, the individual steps required to perform the desired task will be displayed on a simple touchscreen tablet. The visual interface for developing the cobot’s programming is highly similar to a smartphone app.

The development of the programming is done using a combination of clear, graphical icons to represent tasks such as moving to a specific location (“Move Here”), picking up an object (“Pick Up Object”), and waiting for a specified amount of time (“Wait For Two Seconds”). Changing individual steps is also straightforward: the operator simply taps a button, so they do not need to be programmers to modify the program or teach the cobot a new task.

The incredible user-friendliness of cobots is why cobots are considered so revolutionary. Cobots enable experts in their roles to bring automation directly into their hands, allowing them to shift repetitive tasks to machines without requiring an engineering degree.

What Is the “Hand” at the End of a Cobot’s Arm?

Cobots have limitations in what they can accomplish independently — without an end effector, they are only arms. By using end-effector tools, cobots become truly productive, able to physically touch and manipulate objects.

These tools include the simplest type, known as a gripper, which functions like fingers to pick up parts, boxes, and bottles. If you need to work with delicate or slippery materials, such as a sheet of glass or the flat surface of a printed circuit board, then you would likely use vacuum cups instead of a gripper. However, if you need to screw two items together or sand a piece of wood down, then you would want to attach a screw driver or sanding tool to your cobot. On the other hand, if you need to apply glue to a package with precision, then you would likely want to attach a glue applicator tool to your cobot.

One advantage of EOAT is that it can be easily replaced. When you swap out the end effector, it is similar to swapping out the bits for a power drill — you get the ability to perform different jobs with the same basic machine. A cobot could stack boxes at 9 am and help build a product by 1 pm by simply switching its end effector. That flexibility is one of the main reasons cobots will be so beneficial to human workers in the future.

Are Cobots Really the Future of Work?

Cobots are transforming how we view robots at work—from a replacement for people to partners with whom people can collaborate to handle tedious, physically demanding tasks. This approach improves productivity and enables people to focus on more important, innovative ideas rather than repetitive, mundane work that cobots can perform.

The most accurate way to ask this question now is no longer “Did a robot steal a job?” Instead, the correct question should be “Did a cobot make my job better?” — which is exactly the reason why more and more companies view cobots as a good investment, because they are investing in their employees’ well-being and potential. It is not a story of humans vs. machines.

Rather, this is the first stage of a powerful partnership that will lead to a future of collaborative working with humans and robots. As cobots handle the routine, mundane aspects of the job, humans will have the opportunity to do what they do best — create, solve problems, and innovate. The future of work is not going to be less human; it is going to be more so

Conclusion

Cobots are transforming automation away from replacing human work (or at least, isolating it to reinforce it). Cobots’ design emphasizes both safety & ease-of-use, as well as flexibility in placement, enabling humans and machines to be located in close proximity and to divide work based on each’s relative advantages. Humans may provide judgment, flexibility, and quality assurance, especially when product materials or priorities vary; cobots provide consistent, dependable accuracy and reliability in performing repetitive, precision, and physically strenuous motions on an assembly line.

When cobots are properly applied as well as when there is adequate due diligence in assessing the risks associated with their use, the selection of appropriate tools for their use, and the provision of adequate operator training to utilize them safely and effectively — then, cobots have the potential to enhance throughput, minimize error rates, reduce ergonomic strain, and do so in a manner that is compatible with an organization’s established workflow processes without requiring significant changes to its physical facilities.

As sensing, programming, and integration capabilities continue to evolve in cobot technology, “helpful” and “powerful” robots will become increasingly prevalent in manufacturing, warehousing, and laboratory environments. For many organizations, cobots are the most viable way to achieve scalable productivity — as a function of people, not in lieu of people.

FAQs

- What is a cobot?

A cobot (short for collaborative robot) is an automation technology capable of operating in close proximity to people. The cobot can be found working alongside people in a variety of settings, including workspaces. This technology assists with high-precision, repetitive tasks. - How are cobots different from traditional industrial robots?

Industrial robots have historically been faster and capable of carrying heavier payloads than cobots. As a result, they have traditionally required enclosures or fences to protect workers from hazards associated with these machines. Cobots were designed with safety as a priority, ease of deployment, and the ability to share space with workers. - Are cobots safe to work with?

If a cobot is properly evaluated and set up, it can be a safe addition to your workplace. Cobots provide safety through built-in limits (e.g., speed and force), sensors, emergency-stop capabilities, and a job-specific hazard/risk assessment of the workstation and its design. - What are common cobot applications?

There are many ways cobots are used in today’s workforce. They are commonly used for machine tending, light assembly (e.g., screwdriving), packaging, pick-and-place, labeling, and inspection/quality checking. - Will cobots replace human workers?

Many organizations use cobots to assist workers by performing repetitive and/or physically demanding operations, allowing them to focus their time and energy on quality decisions and addressing issues that arise during production.