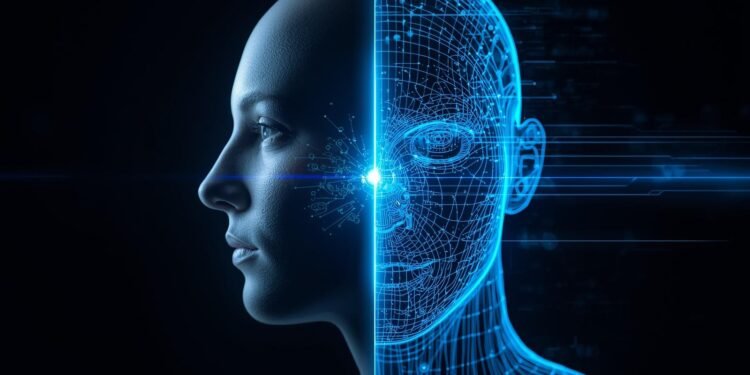

A digital twin (DT) is a dynamic, living virtual model of a physical asset, system, or process, such as a machine, a building, a supply chain, or an entire city. The digital twin (DT) differs from a static three-dimensional model in that it is continually updated with data from the physical asset, ensuring it always reflects the asset’s current condition and performance. As sensors, software logs, and operational records continue to update the model, the digital twin (DT) provides a practical way to understand how something operates, why it operates that way, and what to expect when it occurs.

Ultimately, a digital twin has three main components: (1) the physical asset; (2) the virtual representation of the asset; and (3) the link that exists between the two. The link between physical and virtual assets may include IoT sensors, SCADA systems, ERP data, maintenance records, and other factors such as weather and demand. Once the digital twin is established using this data link, it can support continuous monitoring, diagnostics, and “what if” testing without disrupting ongoing operations. The teams responsible for managing the asset can then simulate the effects of various options (e.g., new configurations, materials, etc.) before implementing them in the physical asset.

Businesses implement digital twins to improve their decision-making at all stages of the asset lifecycle: design, build, operate, and maintain. For example, in engineering and manufacturing, a digital twin enables design validation, reduces defective products, and optimizes product performance. In facility and infrastructure development, a digital twin can optimize energy management, track asset locations, and support reliable asset operation. Additionally, in operationally intense industries, a digital twin can support predictive maintenance by identifying degradation patterns that could lead to earlier failure, reducing downtime, and extending the asset’s service life.

What makes a digital twin so powerful is its ability to connect engineering insights to business outcomes. A digital twin enables the conversion of complex physical systems into measurable, testable models, with the potential to reduce costs by lowering downtime, increasing reliability, improving safety, and mitigating risk. As companies expand their footprint across multiple locations and begin collecting common data across all locations, the digital twin provides a consistent “single source of truth” that enables engineers, operators, and executives to make quicker, more informed decisions.

You have probably experienced a digital twin when you watch your delivery driver’s icon moving across a map on your phone. Although you do not see the actual driver, you are viewing a digital replica that updates in real time. What would be incredibly exciting is to apply the same technology to track something as complex as a jet engine in flight, a metropolitan area’s power grid, or even the human heart.

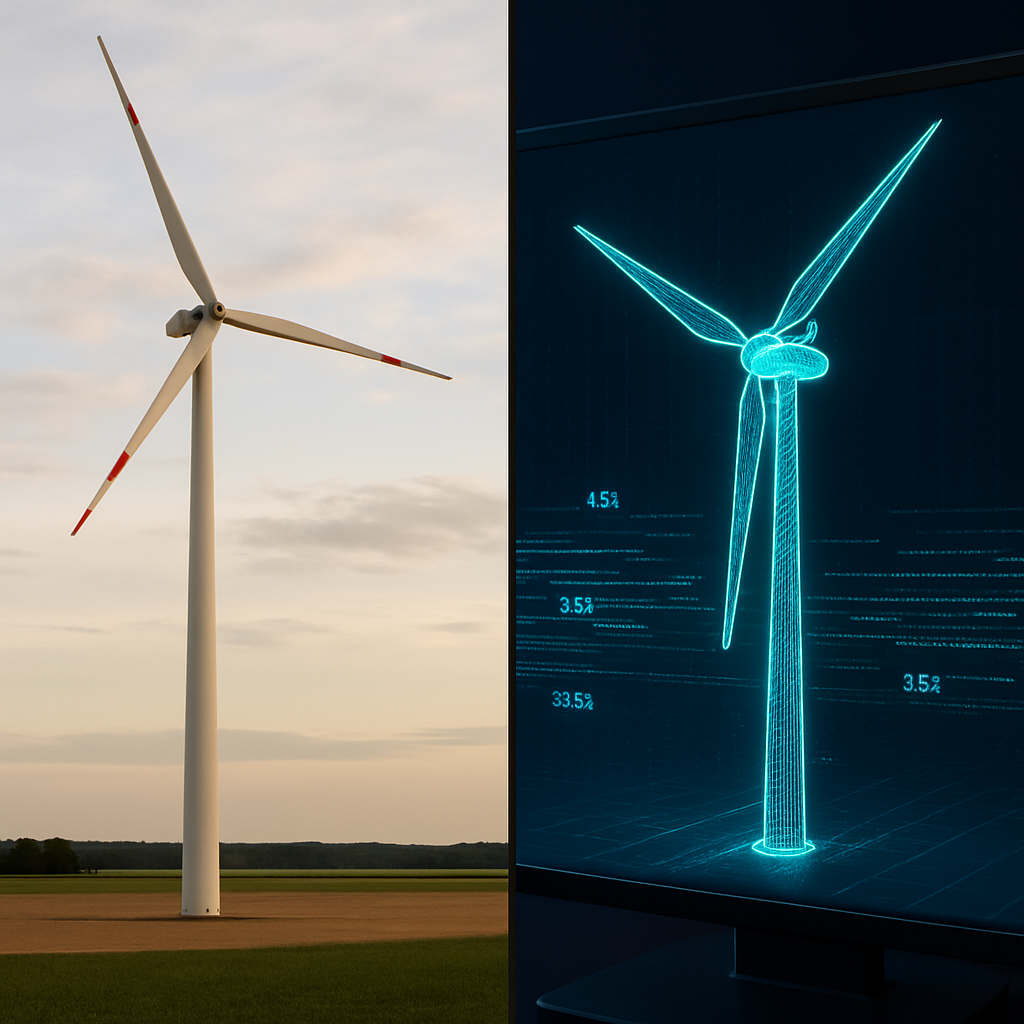

A digital twin is a dynamic virtual model of a physical item. Unlike a static 3D model of a physical object, a digital twin has a direct connection to its physical counterpart, and changes in the physical counterpart will also affect the digital twin in real time. In the example above, the digital model of the wind turbine was not just a static drawing but a dynamic model that mirrored the turbine’s actual speed, stress, and energy production in real time.

So how does a digital twin work? The answer is through continuous data input. Data is collected via sensors (machine nerve endings) attached to the physical object to measure metrics such as temperature and performance. The data collected by these sensors is transmitted to the DT and continuously feeds the digital model. The result is that the digital twin is continuously updated to accurately reflect the physical system’s state.

In addition to representing a significant technological achievement, DT capabilities are beginning to revolutionize many industries. For example, engineers can forecast when failures may occur; cities can test traffic flow and other city-planning ideas before implementing them; and medical professionals can safely simulate treatment options. Digital twins are enabling companies to design smarter products and systems and generate significant new value in the physical world.

So, What Exactly IS a Digital Twin? The “Living Blueprint” Explained

To understand what a digital twin is, we’ll first take a look at something you probably already know about – blueprints of buildings. Blueprints are very good, detailed drawings, but they’re static representations of how a building should look – not how it actually looks right now. A DT brings this concept to life as a “live blueprint.” When a real pipe in a building leaks, the equivalent virtual drop of water will appear in the digital twin. When the afternoon sun heats one room in a building, the corresponding virtual room in the digital twin will also heat up. Essentially, it’s a dynamic, virtual representation that mimics the physical object in real-time.

It is this connection to reality that distinguishes a DT from simply a 3D model or a video game-style simulation. An architectural rendering can give you a picture of how a skyscraper will look, but it cannot tell you if the actual building’s elevators are working properly, which floors have their lighting turned on, etc. A digital twin can do that for you. A digital twin is a data-rich counterpart to the physical asset and, through a continuous data feed, reflects the physical object’s actual condition and health, instant by instant.

Thus, a true digital twin system consists of three primary components: the physical object in the real world (e.g., a wind turbine), its virtual replica (the digital model), and the continuous data stream that links them. The power lies in this link, which converts a simple digital sketch into a smart, virtual replica that provides profound insights.

Virtual Representation: How Real-World Systems Become Digital

Virtual representations are a digital version of a physical object (i.e., a pump, a building, a production line, etc.), that has been captured in a format that both humans and software can interpret and utilize. In addition to resembling the original system, a virtual representation should also capture a system’s behavior, composition, and the ability to evolve over time. Once a DT’s model is linked to an ongoing data feed and is continuously updated, the virtual representation serves as its foundation.

Real-world systems are digitized through three basic processes: capture, structure, and connect. Capture is the process of documenting the real world by collecting data, including drawings, BIM/CAD files, laser scans, GIS maps, equipment tags, and sensor readings. Structure represents taking those records of reality and organizing them in a way that allows for them to be interpreted by humans and software (i.e., defining components, defining relationships among those components, defining the rules that govern the interactions between those components), for example, which valve feeds which line, or which room belongs to which HVAC zone.

Connect refers to linking the structured virtual representation to existing and/or historical datasets, such as IoT sensors, maintenance logs, work orders, and production metrics. It is through the connection of the virtual representation to these data sets that a DT maintains its alignment with the actual physical system.

A good balance between useful and detailed is the key to a successful virtual representation of an asset or process. If the model’s level of detail is too low, it will be of limited use for decision-making. On the other hand, if the model’s level of detail is too high, it may be very expensive to develop and difficult to update and maintain. Many organizations find that the best way to get started on developing a virtual representation of their critical assets and processes are by identifying those areas that are most important (high-risk, high-cost, etc.) and then expanding the scope of the virtual representation as they begin to see the benefits of the program.

As more groups within an organization (engineering, operations, maintenance, energy management, compliance) rely on the virtual representation of critical assets and processes, that same representation can benefit multiple groups simultaneously. The distinction between a basic model and a digital twin is based on how each uses data. A DT provides feedback from the physical asset or process. When the virtual representation is updated with actual data from the physical asset or process, teams can identify anomalous trends, simulate different scenarios, and make informed decisions based on the results.

The virtual representation serves as a “map” of the system, while the digital twin converts that map into a decision-making tool that enables organizations to operate their assets more safely, more efficiently, and more reliably.

Virtual Replica: How Physical Systems Are Mirrored Digitally

Beginning with a digital copy of a physical system (a machine, a building, a car, or even an entire series of processes), the primary goal of a virtual replica is to provide an understanding of the real world, as well as monitor and improve the performance of the physical asset without having to physically interact with it at all times. If a virtual replica is continuously updated with real-world data and used to inform ongoing decisions, it is part of a DT.

Physical systems are digitally represented by a combination of the physical attributes of the system (geometry), the context in which the physical system operates (context), and how the physical system behaves (behavior). Geometry is derived from CAD/BIM models, 3D scans, or drawings that represent the physical appearance and layout of the system. Context describes how the physical system is identified and linked to other physical systems through attributes such as asset tags, location, dependencies, and operating limits.

Behavior is modeled using physics-based rules, analytics, or machine learning, enabling the virtual replica to accurately reflect how the physical system will operate under varying conditions. Once active data pipelines feed the virtual replica (sensor data, control system signals, maintenance records, etc.), it can display the current state, the most recent historical data, and meaningful trends.

A “good enough” virtual replica does not require modeling everything from the beginning. Most teams will build a “good enough” virtual replica by focusing first on key, high-impact areas such as: (1) failure-prone components; (2) energy-consuming equipment; and/or (3) bottlenecks which could cause an outage. Once they have gained confidence, most teams will add additional sensor(s), improve data quality, and create more complex logic, thereby increasing the accuracy and value of their DT over time.

The greatest benefit of a virtual replica is that it enables safer, faster decision-making for operators, engineers, and maintenance teams. Operators can see how well their assets are performing, compare multiple sites, and quickly identify anomalies. Engineers can perform simulations prior to testing and applying any new modifications in the field. Maintenance personnel can use the virtual replica to develop repair plans, minimize unplanned downtime, and confirm if the repairs were successful.

The virtual replica serves as the “view” into the operation each day, while the digital twin transforms that view into predictive information and actionable recommendations to help large organizations improve reliability, efficiency, and lifecycle costs.

The 3 Key Ingredients That Bring a Digital Twin to Life

In essence, what makes a “living” blueprint remain “connected” to the “real world” is through a relatively simple three-ingredient formula, with each of the ingredients having a vital role in making a DT function. To create an operational digital twin, you must have:

- The Physical Object (The “Real Thing”): This refers to the actual asset in the “real world,” the wind turbine spinning in the fields, the Formula One racecar on the track, the pump inside the water system of a city, etc.

- The Sensors (the “Nerve Endings”): These devices, attached to the physical object, will serve as its sense organs. These devices will collect and transmit data based on their placement, including, but not limited to, temperature, vibrations, speed, and location.

- The Virtual Model (the “Digital Copy”): This represents the living blueprint mentioned above, receives sensor data, and mirrors its physical counterpart.

That second component is where the real value is created. Sensors act as nerve endings for machines. Just as your skin is capable of sensing the temperature, a sensor located on a car engine is able to “sense” if the engine has gotten too hot. This concept relates to the Internet of Things (IoT). Think of the IoT as a large group of very small journalists (the sensors), who all communicate over the internet. Each journalist’s task is to gather a specific piece of data and immediately relay it to a central hub—the digital twin.

If this flow of data ceases to exist, the virtual model remains nothing more than a static, lifeless drawing. It is the flow of data generated by sensors and the IoT network that bridges the physical and digital worlds. This enables the virtual model to perceive and comprehend (see, hear, feel) what its real-world counterpart does in real time, thereby converting a simple model into a highly intelligent system. This continuous real-time data transmission is the defining difference between a true DT and simply a simulation.

Real-Time Modeling: Why Live Data Makes Digital Twins Powerful

Real-time modeling is important for digital twins because it provides an accurate representation of what is currently occurring in the system—not just a reflection of past events, nor simply an idealized version of the system as designed.

Real-time modeling enables continuous updates to a virtual system model using data from sensors, software logs, and control systems. This enables teams to understand their current situation, identify potential problems early, and take action to prevent them from becoming incidents, unplanned outages, or unsafe situations.

In practice, real-time modeling takes data inputs (such as temperature, vibration, pressure, energy usage, speed, occupancy, or throughput) and connects them to a model that represents how the system should perform under typical operating conditions. If data input deviates from the expected norm, the model will recognize it as an anomaly and may provide guidance on the most likely cause(s) and next actions.

A DT integrated with real-time modeling can also provide ongoing performance evaluation against defined goals (e.g., efficiency, yield, service level) to support fact-based decision-making rather than speculation.

Real-time modeling offers several significant advantages to support planning and prompt action. Real-time modeling helps prevent downtime for operations teams through alerting and dashboarding capabilities. For maintenance teams, real-time modeling converts condition data into predictive signals that enable “repair before failure” task scheduling.

Additionally, real-time modeling allows leaders to correlate asset performance with organizational Key Performance Indicators (KPIs), thereby identifying where reliability, energy, or quality improvement initiatives are likely to generate the greatest returns. As a result, many companies utilize a DT to prioritize investment in the assets that generate the largest costs or risk exposure.

In addition to supporting resource-allocation prioritization, real-time modeling enables scenario testing. Using real-time modeling, teams can evaluate current conditions and compare them with alternative scenarios or configurations. Teams can also experiment with alternative scenarios virtually without interrupting ongoing production or customer service. The accuracy of the digital twin will improve over time as more data is added; conversely, the accuracy of real-time modeling will improve as it distinguishes normal operational variability from actual problems

In summary, real-time modeling transforms a DT from an inanimate model into a live decision-making tool. Real-time modeling minimizes the gap between when something changes and when the organization knows how to respond, which enables organizations to operate more quickly, safely, and economically.

Digital Twin vs Simulation: What’s the Critical Difference?

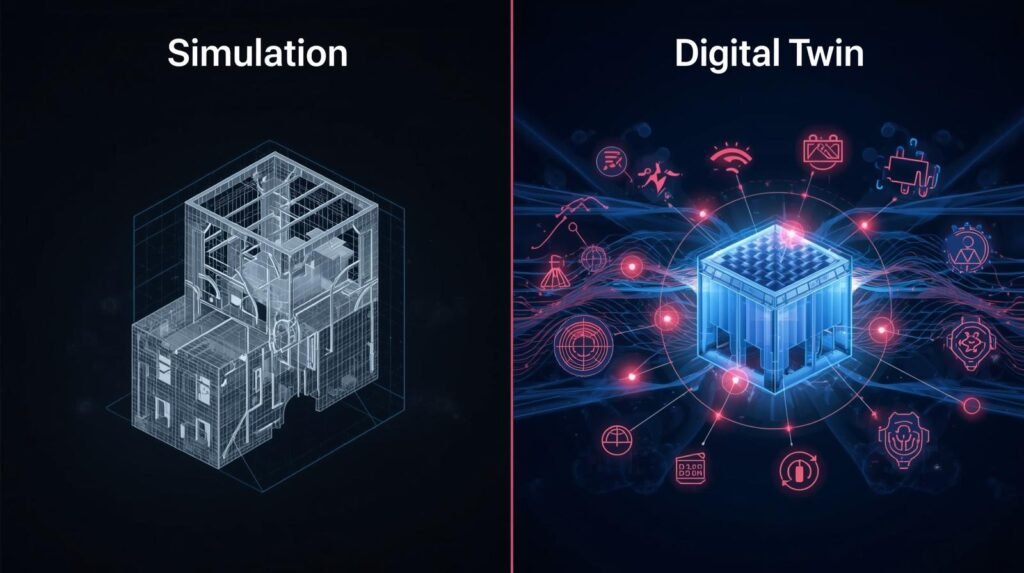

This is going to be confused with a digital model, which is basically a complex simulation – a video game type of flight simulator. In this case, you are able to practice your takeoff, to simulate a flight through a storm, and even to simulate a crash; it has no influence on a real airplane flying in the skies. A simulation is a self-contained digital environment for exploring “what if” scenarios. A simulation is an invaluable tool for training and design, as it is separate from the real world.

A DT is a mirror of the live, two-way data exchange (that we discussed). Therefore, a DT is not a simulated sandbox; it is a real-time mirror. If we compare a DT to an air traffic control tower, we get a sense of how a dynamic map looks. This map provides real-time location, speed, and altitude for all aircraft currently in flight. It is continuously updated with real-world data and therefore reflects the current state.

That is the essence of digital twin technology: mirroring real-time events.

Now, here is the true power of a digital twin: a DT can utilize simulations. An air traffic controller looking at the DT of the airspace can see a real storm developing. Then they can run a lightning-fast simulation within the twin to test out safe new flight routes before they issue a command to the real pilots. The simulation is a function, not the whole system. That predictive capability is one of the most significant advantages of a digital twin, and allows us to ask questions of the future.

Digital Twin vs Simulation: Why Real-Time Updates Change Everything

The biggest distinction between Digital Twin vs Simulation, when individuals consider Digital Twin vs Simulation, is “updates”. Simulations are generally built to answer one particular question (i.e., what happens if demand increases by 100%?, what happens if that piece of equipment fails?). The DT is developed to continuously provide answers based on the evolving conditions of the “real-world”.

When comparing Digital Twin vs. simulation, the largest difference in updates lies in how each model receives input. Simulations rely on static inputs; i.e., assumptions, historical average values, or a pre-determined scenario. Once you run the simulation, you obtain your results, and that is the end of that run.

A DT continues to learn from its environment by receiving continuous feedback on the status of real assets via data (e.g., sensor readings, operational log entries, maintenance histories, and performance metrics). That dynamic relationship creates a paradigm shift between digital twin vs simulation.

The ability to make continuous, real-time updates also enables users to identify small issues before they escalate into downtime, quality issues, or safety concerns. Since digital twins do not require the same level of delay as simulations (e.g., weekly reporting), users can see where things currently stand and immediately identify performance anomalies that may indicate an issue.

One major benefit of a DT is that it enables rapid diagnosis, giving users confidence to take action.

Another area where Digital Twin vs. simulation differ is how decisions are made. Simulations are great for planning and designing: testing different layouts, “stress” conditions, etc., and testing “what if” scenarios. A DT is designed for daily operations; monitoring, alerting, predictive maintenance, etc., and continuous optimization over time. As such, a DT becomes a single source of truth for all parties involved (engineering, operations, and leadership) as they develop a common understanding of their asset(s).

In general, when determining whether to use a Digital Twin or simulation, ask yourself whether you need to experiment with possible scenarios before building or changing something; in that case, simulation may be your best option. If you want an active, dynamic model that stays in sync with a physical asset and continues to improve its performance over time, a digital twin is your best choice.

The most basic of takeaways from Digital Twin vs. simulation is that simulations are excellent tools for conducting powerful experiments, and a DT is a powerful tool for being a companion, because, through real-time updates, a DT remains relevant and useful every hour of the day.

POWERFUL WAY #1: Predicting the Future to Prevent Breakdowns

We have all had times when a car will not start on the morning of a big meeting, or a washer stops mid-cycle. All machines are subject to mechanical failures, and usually these occur at the most inconvenient time. Predictive Maintenance is one of the main issues that Digital Twins address. Instead of waiting until a major mechanical failure occurs, a DT continuously monitors equipment and detects early warning signs that a person or even a routine inspection may miss.

The predictive nature of a Digital Twin allows it to “see” into the near future, allowing a company to take proactive measures to correct potential mechanical failures prior to their occurrence. As stated previously, a Digital Twin of a large wind turbine is not simply a 3D model of the turbine.

It is also receiving a continuous stream of information about its real-world counterpart (e.g., temperature, blade speeds, and micro-vibrations). The DT learns the normal operating characteristics of the wind turbine over time, and once it recognizes an abnormality in the form of a small anomaly (micro-vibration), it sends an alert to the engineers advising them that a particular bearing is beginning to show signs of wear and tear, which could result in a premature failure in several weeks.

As such, the savings to a company are immense. The cost of shutting down an entire system during an emergency and rushing to repair the issue is substantially reduced with a simple, low-cost maintenance plan. In short, a DT for Predictive Maintenance is all about optimizing business operations by transforming “What just broke?” into “What might break next?”. However, what if you wanted to test an entirely new design or push a piece of equipment to its limits without risking damage to the actual equipment? A Digital Twin provides the ultimate virtual testing ground for this purpose.

POWERFUL WAY #2: Safely Testing a Million “What Ifs” in a Virtual World

Designing issues out of products from day one is a different ballgame when you are able to use digital twins as a risk-free creative playground to develop your products instead of just monitoring product performance. If an engineer wanted to develop a completely new concept for a car part, he would have had to spend thousands of dollars in materials alone to develop a prototype of the part, take it to the limit and see when it failed (and hope that he was able to recover the part), and begin again.

However, using a digital twin, the engineer could develop, test, and even crash his part a thousand times in the same time it took him to do it once in the physical world, spend no money on materials, and put no one’s life at risk. Virtual prototyping is changing how we develop inventions.

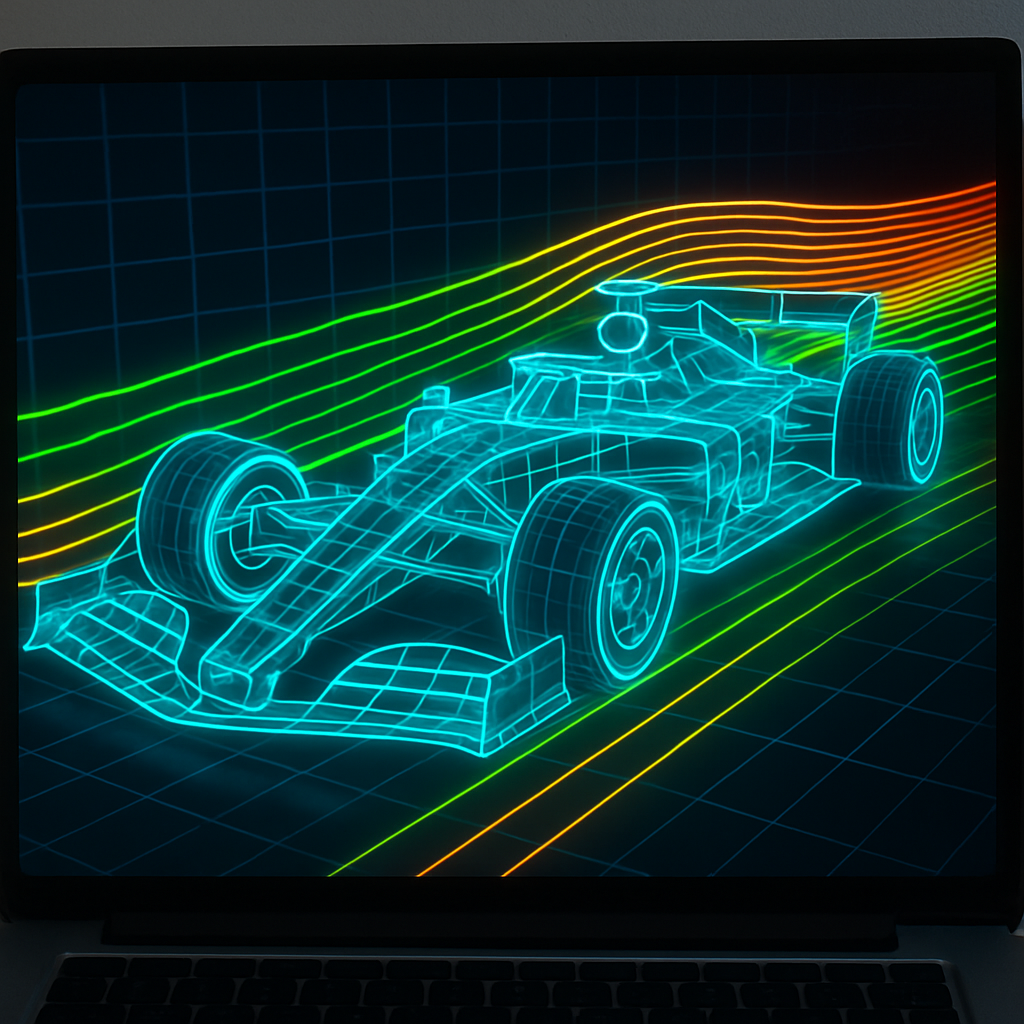

The virtual testing of a digital twin is nowhere more important than in the high-pressure world of Formula 1 racing. F1 teams are always at the forefront of engineering. A hundredth of a second could be the difference in whether they win a race or lose it. Prior to each race, F1 teams create a highly detailed DT in manufacturing – not of a factory – but of their race car.

Using this digital twin, they run multiple simulations to determine how a slight modification to a wing’s shape affects airflow and cornering speed. Unlike a traditional simulation, which can only test a model, a digital twin provides a “living” model that is continually being updated by real-world track data, therefore increasing the accuracy of the tests performed on the digital twin. This is the primary reason why F1 cars change so much from year to year.

While this ability to rapidly innovate is unique to racing, there is no reason the same principles cannot be applied to other technologies, such as developing more fuel-efficient jet engines, stronger, lighter construction materials, and more effective medical implants. This is also where artificial intelligence in digital twin technology allows for human limitations to be exceeded. For example, an engineer may evaluate a dozen possible designs, while an artificial intelligence may evaluate millions of “what if” scenarios against the digital twin during an overnight cycle, enabling the designer to identify the best design for a particular application.

Once the digital twin has been used to design the system to perfection, it will be used for another purpose: to provide the system operator with unprecedented precision and control.

POWERFUL WAY #3: Running Real-World Operations with Superhuman Insight

The transition from a digital twin as a design tool to an operational “mission control” occurs once the system is complete and is operating in the physical world. In addition to generating failure predictions and testing hypothetical “what if” scenarios, the digital twin will provide a current aerial view of all activities occurring simultaneously. The digital twin will not simply be a number-based dashboard. Instead, it will be a live, visual representation of the entire system that is receiving and processing thousands of real-time data feeds. This shift will enable managers to move from reacting to problems to proactively driving success.

To understand the difference, consider a typical traffic map application. While the traffic layer in such an application may indicate where the road is blocked (reactive), a city-wide digital twin will do much more. Not only will it show you where the traffic is backing up, but it will also analyze data from sources such as public transportation, weather stations, and event calendars. Based on this analysis of the DT data, it can suggest or automatically adjust solutions, such as adjusting traffic light timing to alleviate traffic congestion.

That is essentially how to leverage digital twins to improve the efficiency of operations: while the digital twin can provide you with the reporting of what is happening, it can also assist you in writing a new version of the story.

The benefit of a digital twin is that it can provide managers with a “superhuman” view. Think of attempting to operate a large factory solely by walking through it; you can only be in one location at a time. A DT enables you to view the entire factory on a single screen. When a slowdown occurs in one area of the factory, it can create a bottleneck in another area an hour later. One of the largest and most ambitious real-world implementations of digital twins includes entire cities. For example, Singapore uses its virtual model to optimize energy consumption, urban planning, and public safety.

Additionally, the digital twin provides a common platform for delivering the information needed to reveal hidden relationships and connections across various parts of a complex system. The digital twin creates a single point of reference (a single source of truth) that enables teams to collaborate and make decisions quickly and smartly. The ability to visualize and manage large-scale systems can also be applied to smaller-scale systems, including yourself (one).

POWERFUL WAY #4: Designing Products and Treatments Just For You

The concept of a digital duplicate of an individual may represent the technology’s greatest innovation. Digital models of airplane engines and factories are used to enhance mechanical performance, whereas a digital model of a human represents the possibility of a complete transformation of personalized healthcare. One of the largest issues facing individuals today is the “one size fits all” approach to medical care. Soon, physicians can create a digital replica of their patients’ bodies (organs, metabolic functions, etc.) to simulate the effects of various medications in a safe environment before administering them.

Digital Twins represent the future of personalized medicine. A physician could create a digital model of a patient’s heart based upon that patient’s specific MRI images and medical history. A physician could then use those images to simulate a virtual heart and determine how a specific blood pressure medication would affect the patient. In addition to potential adverse reactions to a medication, digital twin (DT) technology could identify the exact dosage required for the patient rather than a statistical average.

These are not fictional concepts; companies are currently developing digital twin technology to create virtual organs, making surgical and therapeutic decisions more accurate and safer. Although digital twin technology has had its greatest impact in healthcare, hyper-personalization will extend to the everyday products and services individuals use regularly. An example is a shoe manufacturing company creating a digital model of each customer’s foot and gait to 3D-print shoes tailored to their needs.

Another example is an automobile manufacturer creating a digital model of each customer’s body to design a driver’s seat that is optimally supportive during extended periods of driving. The ability to model and design products for an individual’s specific needs represents a revolutionary change in how humans interact with technology. Rather than enhancing existing technologies, digital twin technology enables the development of entirely new technologies, customized to meet the needs of an individual

POWERFUL WAY #5: Digital Twin Services That Optimize Assets Using Live Data

They deliver tangible business benefits by integrating real-time sensor data into a virtual asset model. This enables proactive planning to mitigate risk and informed decision-making based on a true understanding of the current state and future trends. The return on investment is driven by reducing the number of unexpected events that require unplanned maintenance or repair, improving operational efficiency, extending asset life, and enhancing regulatory compliance. By using real-time sensor data to identify early warning signs (such as temperature drift, changes in vibration, or drops in pressure), organizations can proactively perform routine maintenance at their convenience rather than resorting to costly “replace everything” maintenance.

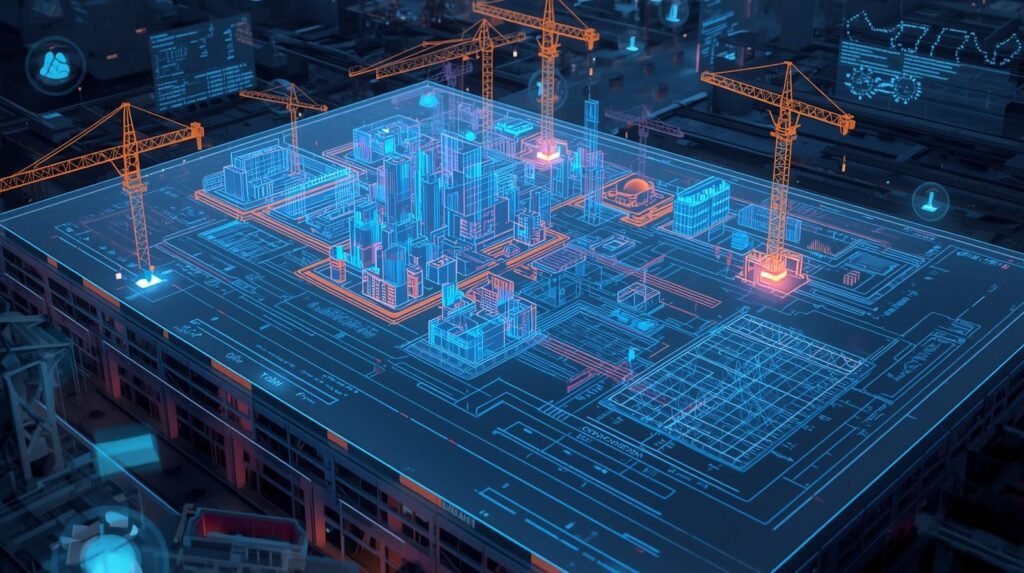

High-cost assets and operations are common use cases for enterprise-level digital twin (DT) projects. For example, a manufacturer can use a digital twin to optimize production line performance by correlating machine data with quality outcomes. In this way, manufacturers can reduce scrap rates, increase productivity, and ultimately enhance overall profitability. Similarly, construction companies can use digital twin technology in construction programs to connect BIM models with field data, enabling tracking of construction progress, monitoring equipment utilization, and managing building systems after handover to support faster commissioning and lower operating costs.

Utility companies can also utilize digital twin technology to balance loads, detect leaks, and minimize disruptions during planned repairs. Transportation logistics and fleet operators can build digital twins of their vehicle fleets and routes to reduce fuel consumption, improve on-time delivery, and optimize route planning.

Digital twin service providers typically measure value using clearly defined KPI’s such as: hours of downtime avoided, maintenance labor reduced, energy savings achieved, warranty claims reduced, and safety incidents avoided. Since digital twin vs simulation provides a continuous flow of “always-on” feedback, the business case for digital twins will continue to grow and strengthen over time as the model becomes more sophisticated and decision-making becomes faster, cheaper, and more accurate across the organization.

Digital Twin Services: Optimize Assets Using Live Data

Digital Twin Services provide businesses with the ability to convert operational data in “real-time” into actionable business decisions for improved performance, reliability, and cost management. Unlike static drawings or periodically generated reports, Digital Twin Services provide a dynamic representation of an asset (chillers, turbines, conveyor lines, etc.) and update the model in real time from real-time signal inputs. The dynamic model can then be used to guide daily activities to support continuous optimization; this is what we call a digital twin.

The main benefit of using Digital Twin Services is faster issue identification. By combining sensor data, control-system outputs, and historical maintenance data, Digital Twin Services can identify trends/abnormalities sooner than would otherwise be possible. For example, when vibration increases, temperature shifts, pressure drops, or energy usage deviates from normal levels, Digital Twin Services can alert your team to the potential issue. This allows your team to take corrective action before the issue results in an outage. Additionally, the model created by the Digital Twin Service provides visibility into component interactions and relationships and, in some cases, enables you to determine the root cause of an issue rather than relying on individual measurements.

Digital Twin Services enable predictive maintenance, more efficient planning, and other capabilities. The way teams perform routine maintenance on equipment has shifted from “just in case” to condition-based servicing when equipment is at a higher risk of failure. This maintenance approach results in less production downtime, less part waste, and an extended asset life. As more data becomes available, the digital twin’s accuracy in providing recommendations improves.

In large-scale enterprise applications, Digital Twin Services are typically deployed across multiple locations and asset types. An overview of all company assets enables users to compare plants, identify which plant is performing best (and why), and decide where to invest capital for the greatest returns. In many cases, companies integrate Digital Twin Services into their work order systems, inventory management tools, and analytics platforms to enable direct action on insights generated by the digital twin.

The objective of Digital Twin Services is to optimize the utilization of company assets by leveraging real-time data to minimize costs, maximize uptime, and mitigate risks associated with asset operations. When properly implemented, a digital twin will be more than just a model; it will be a continuous decision-making tool that ensures alignment among all stakeholders involved in operating company assets and minimizes the impact of disruptions on those operations.

Digital Twin in Construction: Planning, Monitoring, and Control in Real Time

Digital Twin in Construction provides construction teams with a real-time representation of their jobsite (the “live” part) within a digitally connected model, enabling a more informed plan, faster progress tracking, and ultimately better control over project outcomes with fewer surprises.

A static BIM file does not provide the same type of functionality as Digital Twin in Construction; instead, Digital Twin in Construction takes and connects all information about your job, including scheduling, quantity of materials needed, status of equipment, and the physical conditions of the job-site, into one digital model that continues to update. When the connection is maintained throughout the project lifecycle, the Digital Twin in Construction can serve as an updated digital twin to support the team’s daily decisions rather than providing design documentation.

Digital Twin in Construction enables construction teams to evaluate potential site logistics and resource requirements before a project starts. In addition, Digital Twin in Construction creates a model of the job site based on the area, trades, and constraints, helping identify and resolve conflicts across project components. Furthermore, the Digital Twin in Construction will enable construction teams to improve task handover between trades and develop a project timeline grounded in the realities of how long specific tasks will take.

Once the project is underway, the Digital Twin in Construction will serve as a monitoring tool. Comparing actual progress to planned progress will help identify potential issues or challenges within the project. Updates to the model can be generated from a variety of sources, such as mobile inspections, drone aerial photography, laser scanning, GPS tracking of equipment, and materials delivery updates. This real-time comparison of planned-to-actual performance is why the Digital Twin in Construction is considered a useful tool for supporting the team’s daily decision-making.

Digital Twin in Construction provides construction teams with a real-time representation of their jobsite (the “live” part) within a digitally connected model, enabling a more informed plan, faster progress tracking, and ultimately better control over project outcomes with fewer surprises. A static BIM file does not provide the same type of functionality as Digital Twin in Construction; instead, Digital Twin in Construction takes and connects all information about your job, including scheduling, quantity of materials needed, status of equipment, and the physical conditions of the job-site, into one digital model that continues to update.

When the connection is maintained throughout the project lifecycle, the Digital Twin in Construction can serve as an updated digital twin to support the team’s daily decisions rather than providing design documentation.

Digital Twin in Construction enables construction teams to evaluate potential site logistics and resource requirements before a project starts. In addition, Digital Twin in Construction creates a model of the job site based on the area, trades, and constraints, helping identify and resolve conflicts across project components. Furthermore, the Digital Twin in Construction will enable construction teams to improve task handover between trades and develop a project timeline grounded in the realities of how long specific tasks will take. Once the project is underway, the Digital Twin in Construction will serve as a monitoring tool.

Comparing actual progress to planned progress will help identify potential issues or challenges within the project. Updates to the model can be generated from a variety of sources, such as mobile inspections, drone aerial photography, laser scanning, GPS tracking of equipment, and materials delivery updates. This real-time comparison of planned-to-actual performance is why the Digital Twin in Construction is considered a useful tool for supporting the team’s daily decision-making.

The “Brain” of the Twin: Where Does AI Fit In?

If a digital twin is the body made up of all the collected data, then the artificial intelligence (AI) that analyzes this data is the brain of the digital twin. The digital twin receives a continuous stream of data from the device’s sensors. Sensors provide a wide range of measurements, including temperature, pressure, speed, vibration, and more. Having a human interpret the continuous flow of data in real time would be impossible. Therefore, the function of AI is to think for the digital twin by processing the vast amount of data being received by the digital twin and interpreting the data as quickly as possible.

When a doctor examines a patient, they don’t base the examination on a single symptom. Instead, the doctor reviews the patient’s medical history, test results, and overall lifestyle to determine whether any symptoms or patterns indicate an underlying health issue. Likewise, the AI analyzing data from a digital twin continually evaluates hundreds of data points representing the physical object’s performance.

The AI analyzes the digital twin’s normal performance and identifies when it deviates from those levels. Furthermore, the AI can identify subtle deviations that indicate potential future issues with the physical object. This capability of analyzing data is the heart of digital twin data analysis.

The AI’s analysis capabilities enable the digital twin to serve as a wise advisor to the end user. By providing a precise representation of the physical object and an intelligent AI brain, the digital twin can give the end user a view of what is currently happening with the physical object and recommendations for the optimal course of action based on anticipated performance. While the concept of a digital twin with an intelligent AI brain seems powerful and potentially overly complex, it also appears capable of delivering significant value to both the end user and the physical object.

Is Creating a Digital Twin Expensive and Difficult?

That’s a one trillion dollar question – and the answer is: it all depends on the scope. It’s kind of like building with LEGOs. A digital replica of a smart thermostat inside a building is comparable to building a small, simple Lego car. However, creating a digital twin (DT) for an entire jet engine, which has tens of thousands of parts that are highly interactive and operate under extreme conditions, is similar to attempting to tackle that enormous death star model that has one million pieces. The cost to implement a digital twin is not fixed; it increases with the size and complexity of the physical product or system being replicated.

In large-scale projects such as this, creating a digital twin is a substantial undertaking and will require a significant financial commitment to design and develop sensors and AI. Companies are willing to spend millions because they understand that the potential benefits from implementing digital twins could ultimately be in the billions. For example, for a utility company, preventing a single unplanned grid failure could save hundreds of millions of dollars and prevent an entire city from losing electricity.

For a Formula 1 racing team, finding a 100th of a second advantage through the use of a digital twin could be the difference between winning a world championship and returning home without a trophy. You may not need a multimillion-dollar digital twin of your toaster, but the concept is already emerging in lower-cost forms. That app that lets you track your pizza delivery driver’s location is a very basic, low-cost digital twin. Your smartwatch, which tracks your daily step count and heart rate, is a simple health companion. The principal remains the same: an updated digital image of what is happening in the real world.

Your World, Virtually Reimagined: What’s Next?

The small dot on the delivery app’s map has evolved into an endless possibility. We can now observe the same connection between the real and digital worlds, enabling engineers to design better racing cars and city planners to prevent traffic congestion before it happens. Once you could only envision the static object, you can now envision its virtual counterpart that is living and fed by data and working quietly in the background.

This technology will enable us to predict outcomes, test ideas that are too dangerous or expensive to try in the real world, and increase the efficiency of everything from wind turbines to large factories. With these issues resolved, digital twins will demonstrate to us how we can create a safer, smarter, and more responsive world.

However, this is just the tip of the iceberg. One of the biggest challenges scientists have faced so far is developing a digital twin of Earth to model climate change and identify potential solutions. Someday, there may also be a twin of your body that will assist doctors in prescribing perfectly tailored medicine for each patient. The difference between our world and its virtual reflection is becoming less distinct, and in doing so, promises a future that is both connected and well understood.

Comments 1