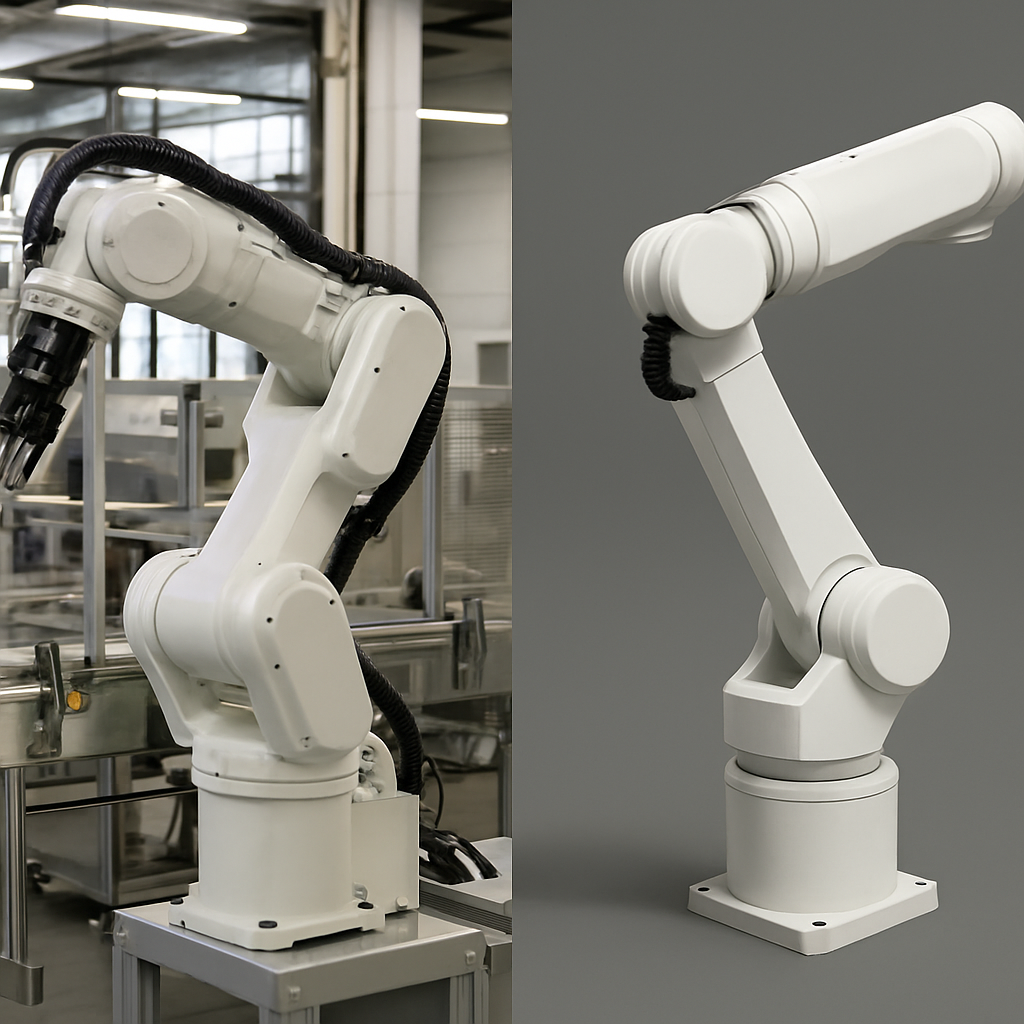

How expensive is the worst way to discover your own mistakes? Once they’re discovered. Think about a company putting millions of dollars toward a brand new robotic arm, watching it smash through parts on its first day of work. One major lesson this company will learn the hard way is the potential pitfalls of creating and programming highly complex, unforgiving machines, such as physical robots.

What if that company had crashed that robot one thousand times without ever having spent a dime or built the robot? That is exactly how robot simulation works. Robot simulation is a program that lets designers build and test a virtual replica of their robots in a digital environment, allowing them to identify and resolve issues before the actual robot is assembled and powered up. Think of it as a flight simulator for robots. In the case of a robot simulation, a disastrous failure is simply a bad line of code to be rewritten.

There are three key reasons why robot simulation is so important: it significantly reduces costs, protects humans and robots from harm, and enables the extensive testing required to train and improve robots.

The fact that there is now a place for designers to virtually test their robots isn’t just some cool technology; it is the driving force behind much of the current advancements in robotics. Examples include surgical robots used in hospitals, the Mars rover, and other sophisticated robots currently in use; almost all were tested in a virtual environment before deployment in the real world. Robot simulation is the primary method for controlling risks within robotics projects.

Summary:

Robot Simulation Software is used to develop, test, and refine robots in a simulated environment before building with actual hardware. Instead of learning through trial and error at high cost, teams can create models of robot arms, mobile robots, tools, sensors, and full workcells to observe how all elements will function and interact. The above facilitates confirmation of reach and clearances, collision detection, cycle time estimation, and validation of basic control logic, without risking equipment damage or safety incidents.

Robot Simulation Software is applicable throughout the robotic development process. Designers can develop refined layouts and tooling designs. Programmers use simulation to debug paths, optimize performance, and test response scenarios, including missing components or delayed signal events. Operations teams may simulate their cell as part of training and to develop safe procedures for startup and recovery.

In addition to the applications listed previously, many platforms offer digital twin capabilities that enable the virtual model to guide updates and improvements after the software’s initial deployment.

The purpose of this article is to define what Robot Simulation Software is, describe what it can (and cannot) predict, and discuss the advantages of utilizing Robot Simulation Software to support the quicker commissioning, lower cost, and more reliable automation of your business. Additionally, the article will outline the key features to look for and provide best practices to help achieve accurate, repeatable results.

The Invisible Blueprint Behind Modern Robotics

Prior to this, the potential to build a sophisticated robot may have seemed unachievable from both engineering and financial perspectives. The enormous risks associated with such massive robotics projects — including the possibility of an expensive crash or a programming error — created a significant barrier to innovation. Robot simulation represents the link that makes such leaps possible: A virtual world in which robots can rehearse, fail, and learn without any consequences to them.

Robot simulation software is the unseen architectural design of almost every modern robot, the digital rehearsal, and the secret training area for the vast majority of modern robots. It’s the area in which mistakes cost nothing, learning is accelerated, and perfection of safety occurs. That’s why robot simulation is important: it allows a high-risk gamble to become a well-practiced performance, converting months of physical labor into days of virtual testing.

The next time you view a video of a dancing robot or a news story about an automated warehouse, you will understand the key component of their success. Their most important task, their thousands of hours of practice, occurred in that digital world prior to it being powered up. You are no longer viewing a machine; You are viewing the invisible tasks that make it all possible.

What is Robot Simulation? Think of it as a Video Game for Robots

The most important part of what robotic simulation software does is similar to a highly realistic video game. However, instead of someone operating the robot with a controller, engineers write the instructions—the code—that tell the simulated robot how to act and perform each task. This is the first way robots are simulated — a digital playground for teaching a robot before it is built.

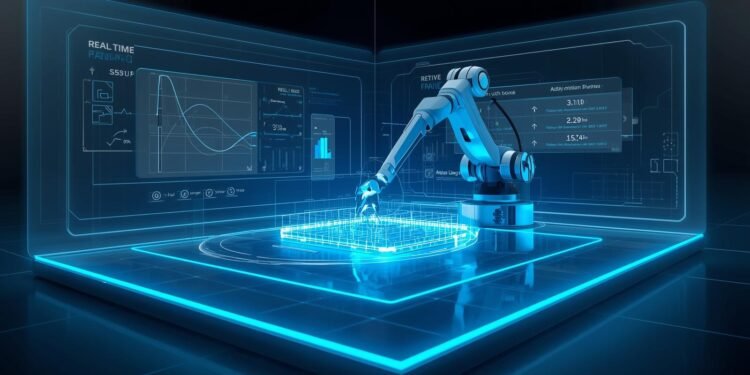

While this digital world contains the simulated robot itself, it also contains a complete replica of the robot’s entire future work area. Whether the work area is a busy factory floor or a highly complex hospital environment, engineers can simulate the robot’s future workspace. The star of the simulated world is the robot’s “digital twin,” an exact 3D replica of the physical machine. It behaves in every way identically to a real machine — it moves, sees, and reacts to its surroundings in the same manner.

Within this simulated world (the digital sandbox), engineers can safely test their robot’s performance. Engineers can repeatedly modify and test their robot’s programming to see how it will react, and run thousands of simulations that would be very difficult to achieve in reality. Can it learn to separate packages? Can it navigate through a cluttered area? Each simulated test run improves the robot’s behavior —by learning from each experience, the robot becomes smarter and more reliable. This process is critical because it is the key to preventing costly and potentially dangerous errors in the real world.

Robotic Simulation: Safely Explore Robot Behavior Without Physical Risk

With Robotic Simulation, you are able to assess how a robot will move, interact with its environment, and respond to different conditions before ever turning on the actual hardware. A simulated world allows you to create many possible scenarios, such as adding obstacles, changing lighting levels, creating slippery floors, simulating crowded aisles in a factory, etc. These simulations allow users to safely explore difficult-to-replicate scenarios at low cost on a physical machine.

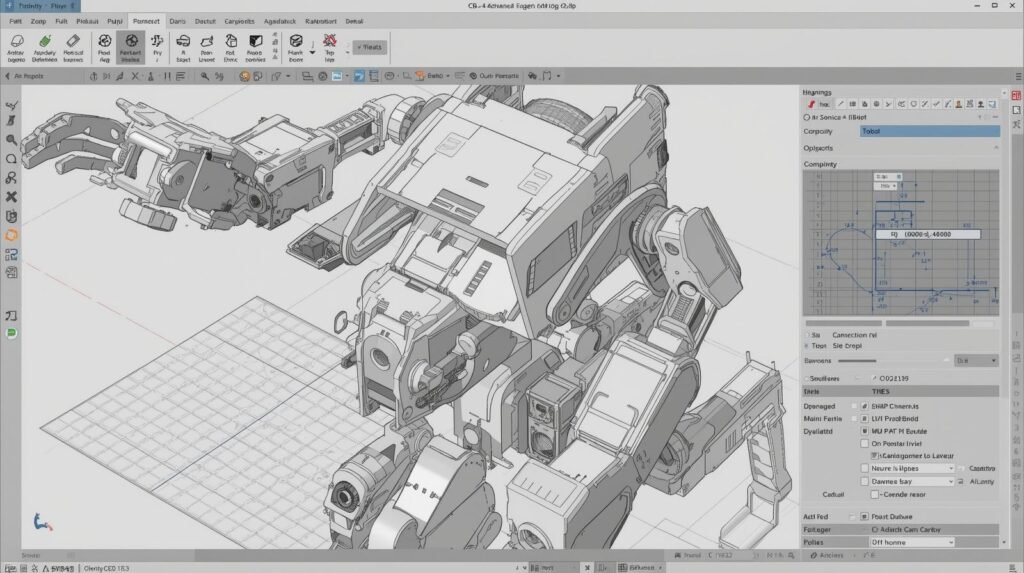

Modern Robot Simulation software allows engineers to import CAD drawings, define joint and motion limits, and use physics-based motion simulation to determine whether a collision will occur or a tip-over is likely due to excessive torque. Additionally, the same Robot Simulation software can be used to analyze motion paths by replaying trajectories, measuring cycle times, and visualizing the robot’s reachability, which helps design the layout and optimize tooling prior to production. Students and novice operators also find robotic simulation an accessible method to study coordinate frames, path planning, and safety zones without worrying about breaking parts.

The safety benefits of robotic simulation extend well beyond preventing collision-related accidents. Robotic Simulation can also help validate emergency stop procedures, speed limiters, and cooperative behavior between robots and humans. Users can also inject simulated sensor noise and latency into the system to model how the control code will respond in the event a camera becomes blurry, a lidar does not receive a return signal, or a gripper slips. Simulating these “what if” scenarios using Robotic Simulation reduces the likelihood that the first failure occurs on the shop floor.

In addition to engineering design support, simulation enables effective communication. Using a digital twin of your cell, you can demonstrate how guards and light curtains work together with motion and simulate throughput before you place an order. Many robotic simulation platforms provide synthetic data for testing vision models and enable detection and grasping across multiple simulated environments. Additionally, using robot simulation software with version control and repeatable test scenarios, all model changes will be recorded, similar to source control in software development.

Robot Simulation is also an ideal method for rapid iteration. Unlike having to wait for lab time, you can run many simulations at one time (parallelizing) and compare different controllers and make parameter adjustments overnight. Combining robot simulation software that supports scripting or ROS integration, you can utilize the same algorithm(s) that you will be deploying, record the results, and debug deterministically. Ultimately, this process shortens commissioning time and provides continuous opportunities for improvement.

In order to obtain the most benefit from your robotic simulation efforts, it is essential to create models that are representative of your actual system: accurate mass properties, friction, payload, and sensor placement. Begin with simple systems and add complexity as your confidence grows. Lastly, use robotic simulation as a decision-making tool, rather than as a guarantor – test critical behaviors on physical equipment when the virtual simulations indicate stability. Utilized properly, robotic simulation software enables robotic simulation to be the safest path to improved performance, reduced unexpected issues, and dependable robotics – an effective step towards quicker and safer product deployments.

Creating a Safety Zone: How Robots Practice Dangerous Jobs in a Virtual World

Robot simulation is vital for many reasons, including serving as an engineering tool that enables the safe development of robots for use alongside humans in hospital or warehouse settings. Within a simulated robot test environment, engineers can develop a robot to respond quickly if a person enters its path, thereby ensuring the robot’s safety before it interacts with a human co-worker.

Simulation also protects the robot and reduces costs associated with its surroundings. An industrial arm can cause significant damage to the surrounding area if it malfunctions; however, in a simulated environment, the robot may perform its task multiple times without causing any damage to itself or the surrounding area. The benefits of offline robot programming are that, when the robot performs its first real-world action, it will be perfect.

The simulated test environment is ideal for testing unexpected events, such as a robot’s emergency stop or an obstruction in its path. If the engineer solves the problem in the simulated environment, the robot will have a reliable, predictable “brain.” The proven code developed in the simulated environment is then uploaded directly into the actual robot, thereby transforming the unknown robotic equipment into a known and trusted partner. The simulated robot is so similar to the actual robot that it has its own unique name.

How Simulation Prevents Million-Dollar Mistakes and Project Delays

In addition to saving you money and time, simulating your robots creates a safe working environment for the humans and robots who will ultimately work together. Simulations enable you to test and validate your design for safety and operation before any equipment is installed in the plant. By creating a safe working environment and allowing you to make corrections before the machines are installed, you reduce costs and risk.

Simulation is like a time machine for testing. While a physical robot or machine is limited by the hours of the workday for testing, a simulated version of your machine or robot can be tested 24/7. Your machine or robot simulations can replicate years of operational testing in a matter of days. The potential for testing a simulated version of your machine or robot is virtually limitless, whereas physical testing is limited.

The idea of testing a simulated version of your machine or robot is so effective that there is even a term for it – virtual commissioning. In essence, virtual commissioning is a full-scale dress rehearsal for your entire plant, conducted entirely on a computer. Engineers can create simulated versions of every piece of equipment and test how they interact before any real machines are installed.

When you are able to catch mistakes before they occur and test at such an accelerated rate, simulation helps turn a high-risk endeavor into a science. However, simulation does more than reduce the risk associated with robotics and automation; it also lowers overall implementation costs and enables greater efficiency, faster production, and higher product quality.

Robot Simulation Software: Test Robot Logic and Motion in Virtual Environments

Robot Simulation Software is designed to enable users to model and test their robots’ motion and logic in a virtual environment before deploying a physical robot. This means that instead of “learning” the robot’s capabilities through trial and error on the factory floor, users can create a digital workspace (or “workcell”), configure the robot’s kinematic parameters, and run simulations to observe every move the robot will make.

Robot Simulation Software allows development teams to validate reach, verify tooling clearances, and detect potential collision areas prior to programming an application, when repair and safety costs are still low.

In addition to validating whether a robot program will simply “run”, Robot Simulation Software enables users to evaluate the overall motion quality of the robot as well. Users can review planned motions (paths), joint limits, accelerations, and singularities, and then edit waypoints and/or speed values to reduce vibration and optimize production cycle times. Additionally, many Robot Simulation Software packages include built-in collision detection and clearance-checking functions, enabling developers to identify near-collision instances that may not be visible through code analysis alone.

With accurate CAD models and payload information, Robot Simulation Software provides a cost-effective way to determine whether the robot has sufficient capacity to manage components without placing excessive loads on the axes or causing unstable motion.

Testing a robot’s logic, similar to motion, is equally important. Using Robot Simulation Software, developers can simulate I/O signals, PLC handshake interactions, safety interlock functionality, and sensor responses to ensure the program behaves properly during both nominal and abnormal operating conditions. For example, users can force a “no part detected” condition, delay an input signal from a conveyor, or simulate a jam to see how the robot program responds and recovers from the event. The ability to repeatedly simulate “what if” scenarios using Robot Simulation Software reduces debugging time and simplifies comparisons across versions.

Virtual Environments also improve collaboration among mechanical, control, and operations groups by enabling them to review the same simulated cell, agree on station layouts, and assess potential risk factors before installing the robotic system. Many manufacturing organizations use robot simulation software to develop a digital twin that enables operators to practice start-up, changeover, and safe shutdown procedures without disrupting production. In addition, if your workflow uses ROS (Robot Operating System) or scripting, Robot Simulation software can be used alongside automated testing, enabling you to test every code change against standard operating scenarios nightly.

In order to have reliable results from a simulation, you should ensure that you are focusing on model fidelity and process discipline. This is achieved by utilizing accurate tool center point locations, representative friction and mass values, and sensor placement that accurately represents actual machine configurations. The best approach is to start with a basic model configuration and add complexity once you have validated that the model’s core functions behave as expected.

Multiple robots, vision guidance systems, and/or human interaction can be added once the core functionality has been validated. Once you have developed a robust simulation model, use it as a powerful filter to quickly identify potential issues, then verify the performance of critical motions on real hardware under controlled conditions. When used properly, Robot Simulation software enables safer commissioning, reduces unexpected events, and facilitates the implementation of robotic systems.

Robotics Simulation Software: Simulate Robotic Systems Before Real-World Deployment

Robotics simulation software enables development teams to test their robotic systems in simulation before deploying them to production. The benefit of this type of software is the ability to simulate an entire cell virtually prior to purchasing and installing hardware. Engineers can upload a customer’s or company’s CAD files and view all components, such as the robot, gripper, sensor(s), and conveyor, interacting in a simulated environment.

Before building a physical prototype, engineers can test the robot’s reach, payload limit, and work area to confirm the design concept is viable. By validating the design concept early in the process, the amount of rework required will be lessened, commissioning times shortened, and ultimately, safer product rollouts will occur.

Risk reduction is another significant advantage of robotics simulation software. In a virtual environment, thousands of cycles can be run, the most extreme (edge) cases tested, and failures examined without damaging any equipment. It is possible to simulate potential collisions, pinch-point locations, and unsafe approaches, and adjust the trajectory and interlock settings accordingly.

Many companies use robotics simulation software to validate their safety logic before anyone approaches the moving arm. Specifically, they test emergency stop functionality, speed limiting devices, and restricted areas. When used with the robot simulation software’s capabilities, such as collision detection and physics-based motion, virtual testing becomes practical and repeatable.

The benefits of Robotics Simulation Software are equally relevant to both control and software development. It enables developers to test how their robots will respond to real-world operating conditions by simulating input/output events, PLC handshakes, and sensor triggers. They can also simulate failure scenarios, such as delays in receiving parts or sensor signals, to ensure the system fails safely and recovers quickly.

Additionally, Robotics Simulation Software enables developers to integrate with other tools via scripting or middleware to run automated tests. The results of each test can be compared with previous versions of the program, making simulation an ongoing improvement process rather than a single point of validation.

Robotics Simulation Software also benefits stakeholders and operators. Stakeholders can view a digital model of the robot and layout, understand the workflow, and approve the layout before it goes into operation, reducing surprises. Operators can practice changeover and recovery procedures using Robotics Simulation Software before going live with the equipment, thereby reducing the learning curve and ensuring consistent operation.

For the simulation to provide the most accurate representation, the model should be realistic and include all physical characteristics, such as mass properties, tool center points, friction, and sensor locations. A good rule of thumb is to start with the simplest model and build complexity as experience and confidence grow.

Ideally, Robotics Simulation Software and Robot Simulation Software should be used as part of a phased validation process, where the designer validates the design virtually first and then validates the most critical aspects on actual hardware in a controlled environment. When done properly, simulation can lead to safer deployments, higher availability, and fewer problems during automation implementation.

Software for Robots: Control, Simulate, and Optimize Robotic Systems

Software for Robots (the software layer) enables the transformation of mechanical components—arms, mobile bases, grippers, cameras—into reliable systems that can sense their environment, decide how to respond, and take appropriate action. At the core of this, in today’s automation environment, Software for Robots encompasses all levels of robotic control—from low-level motor control to high-level task planning —ultimately determining whether a robot is simply functional or truly productive.

At the control level, Software for Robots controls the robot’s motion profile and safety limits, and coordinates the operation of its multiple axes. Additionally, Software for Robots provides real-time feedback from encoders and sensors, ensuring the robot maintains accuracy even as load changes.

For more complex cell environments, Software for Robots communicates with programmable logic controllers (PLCs), conveyor systems, and vision systems, to enable synchronized actions, signal exchanges, and enforced safe states.

Simulation is the quickest way to validate those decisions before exposing the hardware to risk. Robot Simulation Software allows you to create a virtual environment to test reach, detect potential collisions, and confirm cycle time. Using Robot Simulation Software, teams can run “what-if” scenarios—missed picks, sensor noise, part misalignment, and unanticipated stops—and confirm that the logic responds appropriately. Using simulation reduces commissioning time and eliminates costly surprises on the production floor.

Next is optimization. The Software for Robots may evaluate logs from your robot(s), identify where the robot(s) are experiencing inefficiencies (bottlenecks), and suggest ways to improve those areas by creating a smoother path, revising acceleration limits, or improving sequencing. Robot Simulation Software provides support for this process by allowing designers/engineers to visually compare various configurations/layouts of their cell/tray as well as different possible routes/trajectories the robots could take within the cell/tray using the software.

In addition, when the virtual model is consistent with the actual physical model of the cell/tray, Robot Simulation Software will help estimate how much of an impact changing the layout/configuration of the cell/tray will have on throughput before making any physical changes to fixtures or rewriting the programming for the robots.

The most efficient approach to implementing this design would be to create a digital prototype of the cell, simulate it to identify potential issues, and then deploy it. To start, create a digital representation of your tooling/payloads and then utilize Robot Simulation Software to verify the clearance/safety zone requirements for all aspects of the payload/tooling.

Once you have deployed the simulated cell, use the Software for Robots’ monitoring functions to track issues such as downtime, quality, and performance changes over time. Upon identifying any performance degradation, return to the Robot Simulation Software to simulate any proposed changes prior to making any changes to the physical cell and/or writing new programs for the robots.

Ultimately, the Software for Robots combines control, simulation, and optimization into a single continuous cycle: demonstrate it virtually, operate it safely, measure it accurately, and optimize it logically. Robot Simulation Software is also a critical component of this cycle because it reduces costs, time-to-market, and risk associated with experimenting with different cell configurations/routes/trajectories of the cell.

Are There Simulators for Everyone? A Quick Look at the Tools

Just like the software on your phone or computer, robot simulators aren’t one-size-fits-all. Think of it like photo editing: there are incredibly powerful, complex programs for professional photographers, and there are simple, free apps for everyday users. The world of robotics simulation is structured similarly, with tools designed for different goals and budgets. This ensures that everyone, from a giant corporation to a curious student, has a way to start building.

This variety generally falls into two camps:

- Professional Tools: Companies such as Tesla, Boston Dynamics, and many leading robotics/vehicle manufacturers in India use some of the most advanced, proprietary, and highest-performing tools available for building and developing complex robotics and vehicle systems. Some of the key technologies they use include advanced simulation software for performance testing, high-performance actuators, and artificial intelligence/machine learning for navigation. Many companies in India are using digital twin simulations, Python/MATLAB/C++ programming languages for R&D, and computer vision technologies in their robotics developments

- Open-Source & Free Tools: Used by students, hobbyists, and researchers to learn robotics and test new ideas.

For those looking to experiment, the world of free robot simulation software is surprisingly rich. Many of these programs are open-source, meaning a global community of developers contributes to them. A popular open-source robotics simulator, Gazebo, often integrated with the Robot Operating System (ROS), enables anyone to build and test robots on their own computer. This accessibility is creating the invisible blueprint behind modern robotics.

Robot Simulation Tools: Powerful Tools for Designing and Testing Robots

The use of Robot Simulation Tools is crucial for developing and testing robotic systems before committing to physical hardware. With the proper Robot Simulation software, developers can design a virtual workcell, import CAD designs, and study how all components, including robotic arms, mobile robots, grippers, and sensors, will act under actual working conditions. The virtual development process significantly reduces injury risks during testing, eliminates costly crashes, and enables projects to go to market faster than traditional methods.

The primary benefit of using Robot Simulation Tools is the ability to validate designs prior to manufacturing. Developers can determine reach and accessibility, identify collisions, and ensure that fixtures, conveyors, and safety zones are properly located. Many Robot Simulation Tools also offer physics-based motion simulation, enabling developers to determine cycle times, identify singularities, and detect potential joint-limit issues. Additionally, when a developer selects a Robot Simulation Tool that accurately simulates payloads and inertia, the resulting motion in the simulation closely matches the actual motion observed on the shop floor.

In addition to validating the geometric aspects of a robot system, Robot Simulation Tools also validate its logic. Developers can simulate I/O signals, sensor triggers, and PLC handshakes to validate their robot program’s response to various production events. A common approach among developers is to use Robot Simulation Tools to test “what ifs” (e.g., a missing part, a delayed conveyor, or an unsuccessful inspection) to determine how the system will fail and recover. These simulations are valuable tools for debugging, change control, and training, as they enable developers to easily recreate identical tests.

Robot simulation tools enable low-cost experimentation to optimize robotic systems. Using simulation tools, users can test different paths, robot placements, and tooling designs without building each option. The robot simulation software allows users to fine-tune speed, smoothness, and sequencing to minimize idle time while maintaining motion stability and safety. In addition to providing simulation capabilities, some robot simulation tools enable the creation of digital twin workflow models.

Digital twin workflow models enable the virtual representation of a physical system (in this case, the robotic cell) to remain synchronized with the physical system, supporting continuous improvement initiatives. To maximize the benefits of robot simulation tools, high-quality models are essential. This includes ensuring that the tool center point information for each tool being simulated is accurate; using realistic friction values when simulating processes involving friction; ensuring that the mass property data used to simulate the robots and other equipment is accurate; and positioning sensors in the same location as they would be in a physical environment.

When choosing which robot simulation software to utilize, select an application that will allow the best fit for your specific environment (i.e., industrial programming needs, ROS integration, etc.) and establish standardized testing scenarios. When used effectively, robot simulation tools can turn the design and development of robotic systems into a structured, measurable process, enabling development teams to design better systems and ultimately reducing the number of “surprises” during deployment.

Robot Design Software: Design, Model, and Refine Robots Digitally

The first point to make about Robot Design Software is that it enables engineers to design, model, and iterate on their robot in a digital format before cutting metal or ordering parts. Robot Design Software is the first step in the robotic development process. Using Robot Design Software, engineers can develop the robot’s mechanical structure, define the geometry of each joint and link, and rapidly compare a range of concepts. Using Robot Design Software will enable faster design iterations, reduce prototyping costs, and facilitate collaboration across engineering disciplines (mechanical, electrical, and control).

In practice, the most efficient workflow begins with using Robot Design Software to define geometry and configuration. Engineers will begin defining frames, arms, end effectors, and mounting plates in Robot Design Software. In addition, they will verify clearances and accessibility to perform maintenance.

Robot Design Software provides an effective method of documenting essential parameters such as link lengths, joint limits, and tool center points to ensure consistency throughout the remainder of the development process. Following verification of the design, engineers can combine the outputs of Robot Design Software and Robot Simulation Software to observe how the robot performs under motion, acceleration, and interaction with the surrounding environment.

During this simulation phase, many problems are identified. Robot Simulation Software may be used to simulate collisions, determine whether the robot can reach all desired locations, and identify poor positions or singularities that could cause issues during robot assembly. By testing different gripper designs,

fixture locations, and approach angles using Robot Simulation Software, engineers can reduce cycle times and increase the reliability of their robotic system. In addition, when Robot Design Software outputs accurate mass properties and inertia values, the results obtained from Robot Simulation Software will be significantly closer to the actual performance of the robot.

Robot Design Software enables further design refinement based on payload, stiffness, repeatability, and safety requirements, and provides options to increase link size, relocate motors, or modify gearing. The changes are then verified to determine whether they improve the overall design. Robot Simulation Software is another layer for verifying motion profiles, ensuring joint torque remains within established limits, and demonstrating how the robot will handle extreme situations, such as tight tolerances or sudden stops. Used together, Robot Design Software and Robot Simulation Software help the team achieve a design that is both manufacturable and deployable.

In addition to engineering benefits, Robot Design Software enhances communication. A clear digital model enables stakeholders to review and discuss concepts, plan cell layouts, and prepare assembly instructions. On the other hand, Robot Simulation Software may enable the creation of visual examples for training and process approval, reducing the likelihood of unpleasant surprises during commissioning.

To maximize the effectiveness of your Robot Design Software and Robot Simulation Software, it is essential to maintain consistency across your models: consistent coordinate frames, realistic joint limits, and consistent tracking revisions. By developing sound Robot Design Software practices and establishing repeatable testing methods using Robot Simulation Software, teams will be able to design robots faster, make decisions sooner, and develop and refine their robotic designs with confidence.

What Is a ‘Digital Twin’? Your Robot’s Perfect Virtual Copy

A digital twin in robotic automation creates an exact replica of the physical robot (including all part details) and exists entirely in a digital environment, designed to simulate the robot’s movements.

Using simulation software, the digital twin can model the robotic arm’s physics and joint motion. In addition to understanding the movements of the robotic arms and joints, the simulation software also understands the components of the robot, such as the motor speed, weight of the individual parts, and the entire robot, and how they interact with each other. The combination of these two factors enables the engineer to test the robot in a variety of scenarios, including lifting heavy objects without damaging it.

Additionally, simulation greatly enhances the ability to accurately identify potential problems associated with a particular operation. For example, the simulation could determine that a particular movement would cause the arm to rotate too quickly or collide with another object. These issues could then be addressed before the robot was actually built.

Therefore, when a problem is identified during testing, engineers do not have to worry about making changes to the robot after it has been built. The solution to the problem identified during the simulation can be incorporated into the robot design at any stage prior to construction, ensuring the final product functions properly.

From Virtual Practice to Real-World Action: Making the Jump from Screen to Factory Floor

If all that simulated practice doesn’t have a way to be used, then it’s worthless. But how does a perfect robotic performance in a simulation translate into the real world? Surprisingly enough, it is relatively easy. The brain perfected in the simulation (the exact code that tells the robot each time to move or lift) can simply be copied and uploaded to the physical robot. It is similar to writing a song on your computer and then uploading the finished file to a speaker to listen to it. The work done in the virtual world will serve as the physical robot’s direct instruction manual.

This powerful capability to copy code and upload it to the physical robot is called offline robot programming. The “off-line” portion of this term represents the revolutionary aspects of this technique. Off-line robot programming means that the same engineering team responsible for developing and testing a complex new task for a robot does not need the robot itself to be physically present during development and testing.

Historically, robot programming required shutting down expensive manufacturing equipment, such as assembly lines, so engineers could manually and slowly teach a robot its new task. With today’s technology, the same engineering team can now complete the same process using a separate computer while the factory floor remains operational.

There are many advantages of using offline robot programming. For example, imagine a robot on an assembly line currently packing boxes. While the robot is operating, an engineer could be programming and simulating the robot’s next task (stacking pallets). Once the new program is developed and tested in the virtual environment, it can be sent to the robot during a short break. By using offline robot programming, the robot will never sit idle for long periods waiting for reprogramming, ensuring production lines operate at maximum efficiency. This seamless transition from simulation to the real world enables modern robotics to achieve its full potential in speed, safety, and cost savings.

Where is Simulation Used? From Exploring Mars to Your Living Room

The application of simulation extends beyond manufacturing to areas such as space exploration and home environments. The applications of simulation are numerous and span all forms of robotics, enabling experimentation and problem-solving at lower cost and in a safer environment than in the real world.

NASA’s Mars rovers are among the best examples of simulation in use. Due to a 20-minute round-trip communication lag (and therefore cannot ‘joystick’ the rover), NASA engineers have created an extremely realistic digital model of the rover and Martian terrain. Before sending any commands across millions of miles, engineers practice every possible movement in the digital model to prevent the rover from getting stuck or tipping over.

In addition to NASA, many automobile manufacturers utilize simulation technology to design and plan their production lines, including simulating the motion and coordination of multiple robotic arms to perform tasks such as welding, painting, and assembling automobiles.

At an even smaller scale, the company that manufactured your robot vacuum used simulation technology to program the robot to navigate thousands of virtual living rooms, avoiding obstacles such as chair legs and electrical cords before building a single physical prototype.

Simulation is a ‘what-if’ sandbox for modern robotics that serves as a fundamental tool for large corporations and small startups alike. Therefore, you may wonder whether this type of technology is available only to large companies or whether individuals can begin experimenting with simulation-based technologies.

Conclusion

Robot simulation software has transformed the design and delivery of modern robots by enabling engineering teams to test new concepts, motions, and control algorithms virtually, quickly, and safely before interacting with a physical machine. In addition to demonstrating robotic motion, reach, collision detection, cycle time, and control logic in a simulated environment, engineers can use this type of simulation to identify and address potential issues before damaging hardware, disrupting production, or exposing safety concerns in the manufacturing area.

Additionally, simulation provides a wide range of benefits throughout the entire project process, including: Designers refining their designs to include idealized tooling and layouts; Programmers validating input/output signals and failure modes; Managers estimating throughput and timelines with greater accuracy. With advancements in digital twin workflows, synthetic data generation, and AI-driven development processes, simulation is evolving into a foundational element of continuous improvement, not merely a pre-production validation method.

The key to using robot simulation software effectively is to use accurate models of payload, friction, sensor outputs, and joint limits, run repeatable simulations, and view simulation results as a guide rather than a definitive indicator of real-world performance. When used correctly, robot simulation software enables robotics teams to transition from concept to commissioning much more rapidly, eliminates unexpected events, improves system reliability, and develops safer, more reliable systems that operate as expected in real-world operating environments.

FAQ’s

- Q. What does robot simulation software do?

A. Robot simulation software is an artificial environment in which you create models of robots, tools, and workcells to evaluate motion, logic, and performance prior to actual equipment implementation. - Q. Why should I use robot simulation before I deploy it?

A. Using simulation will help prevent collisions, reach problems, timing issues, and logic issues that would cause safety issues, downtime, and costs associated with reworking equipment during the initial setup/commissioning process. - Q. What can robot simulation software test and determine?

A. Reachability, collision/clearance, cycle time, joint limits, trajectory, sensor behavior, and basic I/O or process sequence (dependent upon the software platform) are all possible tests/measures. - Q. How accurately do simulation results match real-world robots?

A. The accuracy of simulation results depends on the quality of the modeled payload, friction, inertial data, calibration (TCP, Frames), and similarity of the virtual cell to the actual cell. Critical behaviors will always require testing in a real-world setting. - Q. What should I be looking at when selecting robot simulation software?

A. Import CAD files, realistic physics, collision detection, support for your robot manufacturers, programming workflow, integration with other systems (i.e., PLC, ROS), and robust debugging/visualization tools.

Comments 2