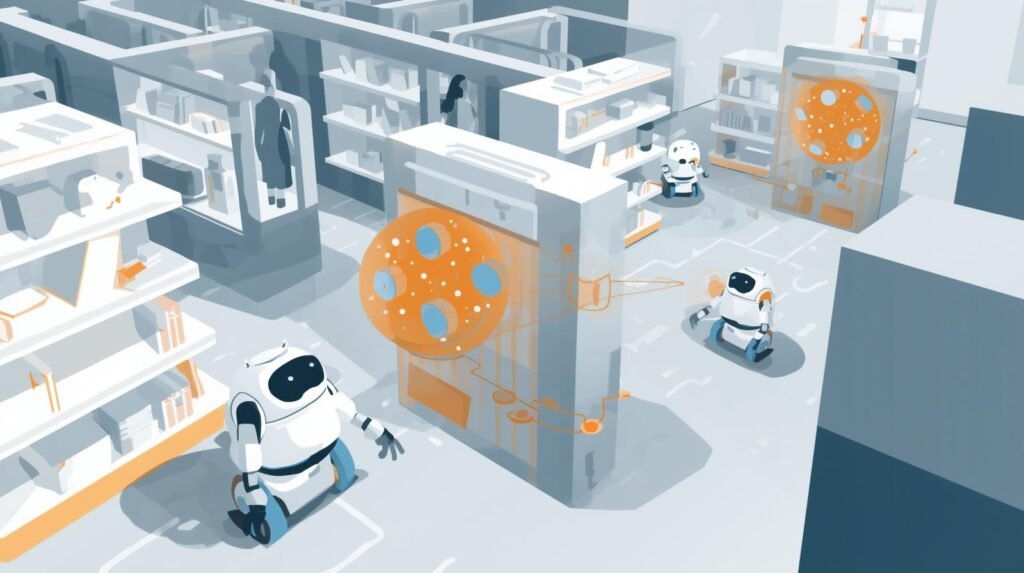

You may be familiar with the autonomous Roomba vacuum cleaner as you watch it move through a house in a seemingly intelligent manner. Consider a version of this Roomba with a Ph.D., capable of riding an elevator and traveling at speed to deliver life-saving medications to patients in a busy hospital. This is the world of Autonomous Mobile Robots (AMRs), and they are quietly advancing our most important services from the inside out.

What distinguishes AMRs from Automated Guided Vehicles (AGVs) used in manufacturing facilities for decades is the word “autonomous” in their name. While warehouse managers use AGVs that resemble trains and run on tracks, where AGVs move only along a predetermined magnetic or paint stri

p on the ground, AMRs are more like cars with GPS and extremely cautious drivers. This major difference in how AMRs and AGVs move through space changes everything: an AMR will create its own route and maneuver to avoid obstacles in its path.

This is the intelligence that enables AMRs to navigate complex environments and directly impacts your life. Think about that last-minute order you placed online. A large number of AMRs working together within a fulfillment center can swarm to find your item, avoid traffic jams, and deliver it to the shipping area several hours sooner than if they did not have the ability to change directions on the fly. The same technology used to improve logistics for mobile robots is also transforming healthcare.

Rather than having nurses spend their valuable time on errands, AMRs can deliver lab samples, food, and other medical supplies to areas of the hospital where they are needed, allowing highly trained medical professionals to focus on what is most important — patient care. The fact that these smart, adaptable robots are no longer a futuristic concept but rather the unseen engines that make our world move faster, safer, and more efficiently means we are now entering a new era.

Summary

AMRs are transforming warehouse and hospital operations by safely and autonomously moving needed supplies through crowded indoor spaces. Unlike earlier “guided” vehicles, which were limited to being directed by a track or magnetic tape, AMRs navigate their surroundings using LiDAR and cameras and employ sensor fusion to interpret visual data from those sensors as distance information and to detect objects and people.

One of the fundamental technologies enabling this capability is SLAM (Simultaneous Localization and Mapping). The “map vs. position” problem has been solved by enabling the robot to simultaneously generate a map of the area and determine its current location relative to that map in real time.

With knowledge of its own location, the AMR uses dynamic path planning – similar to a GPS navigation application – to select the most optimal route to travel based upon factors other than simply selecting the shortest route possible. If the AMR encounters a change in its surroundings, it can rapidly re-route itself and avoid congested areas.

The safety aspect of AMR navigation is also critical to their operation. The protective awareness zone created by the sensors surrounding the robot allows it to slow down, stop, or steer away from potential hazards (e.g., obstacles) and even anticipate the motion of individuals approaching the robot, enabling smoother avoidance.

Finally, at larger scales, fleet management software enables coordination of multiple robots and prevents congestion by efficiently assigning specific tasks to each robot. Additionally, AMR behavior varies significantly by operating environment: warehouse AMRs prioritize speed and throughput, while hospital AMRs prioritize caution and socially aware movement. These combined capabilities enable AMRs to serve as reliable team members, reducing routine transport tasks and increasing overall operational efficiency.

Autonomous Mobile Robots (AMRs): Move Independently without Fixed Paths

Autonomous Mobile Robots (AMRs) are self-driving robots that can carry items, supplies, or equipment within an indoor space by traveling along paths without fixed tracks or magnetic tape. Autonomous Mobile Robots (AMRs) are different from earlier Automated Guided Vehicles (AGVs) because AMRs can observe their environment, determine a route to follow, and adjust if there is a change in the environment; for example, if a person enters the aisle or a cart blocks a pathway.

Most Autonomous Mobile Robots (AMRs) use a combination of sensors, including LiDAR, depth cameras, stereo vision, ultrasonic sensors, and wheel odometry, to support navigation. The data collected by these sensors will enable the robot to create or reference a map, and once a map exists, it will use this information to localize its position on the map (typically via SLAM: Simultaneous Localization And Mapping). Once the robot is localized, it will apply a path-planning algorithm to select a safe, efficient path to the target location and continuously replan in real time to avoid obstacles.

Warehouses are increasingly using Autonomous Mobile Robots (AMRs) to assist with picking, put-away, replenishment, and line-side delivery. Autonomous mobile robots may reduce walking times for warehouse workers, improve traffic flow through congested aisles, and maintain workflow during shift changes. Hospitals are utilizing Autonomous Mobile Robots (AMRs) to transport items such as linens, food, medications (in secure compartments), and waste, enabling hospital staff to provide better patient care and spend less time making routine deliveries.

Autonomous mobile robots offer several advantages; most notably, their flexibility. For example, if a facility’s layout changes due to new racking systems, temporary construction, or ward reconfiguration, the robot’s navigation system can typically be updated via software and remapped without requiring any changes to the physical infrastructure.

Additionally, fleet management software will coordinate the use of multiple Autonomous Mobile Robots (AMRs), assign tasks to each robot, manage charging schedules, prevent collisions between robots, and prioritize urgent deliveries.

An additional consideration is safety. Autonomous mobile robots operate at speeds limited by local regulations, are restricted to predetermined geofenced zones, can stop in emergencies, and are designed to operate safely around humans.

Successful implementations of Autonomous Mobile Robots (AMRs) still rely on process improvements such as designated pick-up/drop-off locations, accurate labeling, reliable Wi-Fi connectivity (with localized autonomy available where applicable), and the proper training for warehouse employees to effectively work with Autonomous Mobile Robots (AMRs). Once the basic requirements for effective implementation of Autonomous Mobile Robots (AMRs) are met, they can deliver measurable increases in throughput, consistency, and service quality.

Robot Navigation: Robot navigation enables safe movement through complex indoor spaces

Robot Navigation provides the ability for robots to safely navigate through indoor environments with many obstacles by providing a robotic vehicle with a means of determining its current location within the space, identifying objects in the area it is moving through, and selecting a course to take toward a target destination without causing collisions along the way.

Robot Navigation has made significant contributions in the areas of warehouse management, hospital operations, and factory automation, as it has enabled robots to transition from being remotely controlled devices to becoming dependable coworkers capable of safely navigating the same spaces that people use, such as people, carts, doors, and other possible hazards as well as changes to the layout of the area.

The basis of Robot Navigation is the functions of mapping, localization, and path planning, which function together. The first function, mapping, is used to generate a representation of the environment; the second function, localization, is used to determine the robotic vehicle’s location based upon this representation, typically by fusing data from sensors including LiDAR, camera images, wheel encoder data and inertial data; and the third function, path planning, is used to select a route.

Finally, obstacle avoidance will adjust the robotic vehicle’s speed and/or direction of travel based upon objects that may have entered the space while the robotic vehicle was in transit. For this reason, Robot Navigation can handle the complex movements of robotic vehicles in busy hallways, narrow aisles, and temporarily obstructed paths.

Given that Autonomous Mobile Robots (AMRs) operate in dynamic environments, navigation is critical because their operating conditions constantly change. Therefore, several AMRs use SLAM (Simultaneous Localization And Mapping), which enables rapid deployment and operation despite changes in the space layout, such as the movement of shelves or corridor reconfiguration.

Additionally, good Robot Navigation enables “Human-Aware” behavior in which robots will yield to traffic at intersections, slow down or stop when approaching individuals, maintain sufficient distance when passing individuals, and otherwise act in a manner consistent with common sense. As a result, the frequency of near misses and the perception that a robotic vehicle is unpredictable are reduced.

Fleet operations add an additional layer of complexity when multiple AMRs operate in the same geographic area. Robot Navigation must manage traffic flow, eliminate deadlocks, and optimize both speed and safety. This is done through fleet software that directs each AMR (or assigns tasks), establishes one-way zones, and redirects the robot around congested areas. Each AMR still does its own navigation and obstacle avoidance.

In hospital settings, Robot Navigation would include, but not be limited to, integrating with elevators, controlling doors, and establishing access restrictions in areas the hospital wants to limit. In warehouse settings,

Robot Navigation would direct the fastest route to a pick face and, at the same time, avoid forklifts and staging zones. As sensor technology advances and algorithms become more refined and complex, Robot Navigation will continue to enhance the safety, smoothness, and utility of AMRs in their daily indoor work environments.

Mobile Robot Navigation: Navigation systems designed for moving robots in real spaces

Mobile Robot Navigation involves both the physical components (hardware) and the logical elements (software) to enable a mobile robot to navigate a real-world environment rather than a laboratory setting. Within warehouses, hospitals, and campus settings, Mobile Robot Navigation enables the robot to safely navigate from point “A” to point “B” while avoiding other entities, including people, doors, carts, and unanticipated obstacles. Strong Mobile Robot Navigation is the difference between an experimental pilot project and a reliable day-to-day operation for Autonomous Mobile Robots (AMRs).

The general stack of Mobile Robot Navigation begins with Perception. The various sensors used by the robot to perceive its environment, including LiDAR, depth cameras, stereo cameras, ultrasonic sensors, and wheel odometry, allow the robot to visually see the walls, shelves, and moving objects within its environment. Mapping and Localization are the next two levels of Mobile Robot Navigation.

Most AMRs use Simultaneous Localization And Mapping (SLAM) to build a map of their environment and concurrently determine their location within it. Once the robot accurately determines its location, the Mobile Robot Navigation system will plan and control the robot’s motion.

The global planning level determines the overall route to the destination, while the local planning level dynamically adjusts the robot’s speed, stops it as needed, and steers around moving obstacles. The ability of Mobile Robot Navigation systems to respond locally is one of the primary reasons AMRs can operate in active facilities alongside other entities, such as people, without requiring fixed paths or tracks. A good Mobile Robot Navigation system must also account for constraints such as turning radius, payload, floor conditions, and safe stopping distance.

Real-world implementations of mobile robots go beyond simply clearing an obstacle course. The navigation of a mobile robot often involves interacting with traffic patterns (one-way streets, right-of-way laws, speed limits, etc.), geofences that define restricted zones, and specific building features (e.g., elevators, auto-actuated doors). If many AMRs operate in the same space, coordinating their motion (fleet management) helps minimize bottlenecks and reduces the risk of two or more AMRs blocking each other while each unit continues to run its own local Mobile Robot Navigation.

While “smart” Mobile Robot Navigation is beneficial, the most effective Mobile Robot Navigation is predictable. Employees should be able to understand how the robot operates across different scenarios (intersections, turns, signaling intent) and interact with the robot appropriately during handoffs.

By providing consistent, reliable sensing, proper planner tuning, and well-defined operating rules, Mobile Robot Navigation enables AMRs to operate safely and efficiently in the real world every day.

Indoor Navigation: Indoor navigation allows robots to operate where GPS is unavailable

Indoor navigation enables robots to operate in environments such as warehouses, hospitals, and manufacturing plants where GPS service is unavailable or unreliable. The primary role of indoor navigation is to enable robots to determine their location and orientation and to detect obstacles and other hazards in their surroundings. For autonomous mobile robots (AMRs), indoor navigation underpins safe, repeatable transportation tasks in busy hallways and across changing floor layouts.

Most indoor navigation systems consist of both hardware (sensors) and software, rather than relying on a single data source. Cameras and LiDAR are used to detect walls, doors, shelving, and other objects or landmarks, while wheel encoders and inertial measurement units (IMUs) measure the robot’s motion between sensor readings.

Many AMRs use simultaneous localization and mapping (SLAM), which enables the robot to create or update a map of its environment and localize itself on that map simultaneously. The use of SLAM enables the robot to adapt to changing environments (e.g., a pallet temporarily obstructing an aisle or a hallway filled with people).

In addition to using sensors and SLAM, many indoor navigation systems can also use infrastructure-based aids when high precision or stability is required. Examples of these aids include placing QR codes or AprilTags at various locations throughout the facility; using reflective markers for LiDAR; measuring Wi-Fi round-trip time (RTT); using Bluetooth beacons; or using UWB anchors for precise distance measurements.

Indoor navigation may also interact with physical infrastructure in certain applications (e.g., hospital elevator control, door automation, and restricted-zone enforcement near patient areas). In warehouse settings, indoor navigation systems are commonly integrated with geofencing to define forklift travel routes, speed limits at intersections, and “no-go” zones in staging areas.

Smooth Indoor Navigation is as much about getting to a place without trouble from other people as it is about actually arriving at that place. The ability of an AMR to detect obstacles in its path and to develop plans for its route locally allows it to reduce speed, yield to pedestrians, stop, or even change its route on the fly. Additionally, coordinating multiple AMRs (i.e., fleet) can further mitigate congestion caused by multiple robots traveling the same paths and accessing the same charging stations.

In practice, Indoor Navigation is successful when maps remain up to date, routes have well-defined pickup/drop-off areas, and locations provide stable wireless connectivity where needed. When all these elements work in harmony, Indoor Navigation enables AMRs to consistently deliver safe indoor mobility without GPS, while also increasing AMR uptime and overall operational efficiency.

Beyond Human Eyes: How Do These Robots “See” the World Around Them?

AMRs see their environment using a technology that is probably unfamiliar to you: LiDAR. Think of a small, spinning lighthouse on top of the robot. It sends out thousands of harmless, invisible laser beams per second. The travel time of each laser as it hits walls, shelves, and people creates a three-dimensional model of the environment. The robot’s ability to navigate the environment using natural features enables it to move through a building without track tape or special floor markings.

LiDAR is very good at reading the shape and distance of objects in the environment, but has no ability to read a sign or recognize a particular object. It is here that a different technology comes into play: cameras. These are similar to the cameras on your phone. These cameras provide the high-resolution detail needed for the robot to read a barcode on a box, read the number on the floor next to an elevator, or determine whether a person is walking by or standing against a fixed pillar.

The unique aspect of these robots is the fusion of LiDAR and camera data. This is called sensor fusion, and it creates a more comprehensive and reliable view of reality than would be possible when each sensor is used individually (e.g., as you use both your eyes and ears to ensure your safety when crossing the street).

The robot combines high-resolution images from the cameras with an accurate 3-D model derived from LiDAR to achieve a nearly supernatural level of awareness. However, knowing its environment is only the first step. The robot must now use the collected data to create a persistent, map-based representation of the environment to enable navigation.

How Does a Robot Build a Map of a Place It’s Never Been?

The robot uses its LiDAR and camera systems to capture images of its surroundings. These images are just snapshots, and they don’t create a long-term map of the area. Therefore, this system must be able to capture all of those images in real time and generate a permanent, accurate map of the area, which is a very complex task. To accomplish this, the robot will use a technique called simultaneous localization and mapping (SLAM).

SLAM addresses two fundamental problems simultaneously. The first is mapping (creating a map), and the second is localization (determining the robot’s position relative to the map). Think about being in a dark, unfamiliar building. All you have is a flashlight and a blank piece of paper. If you were going to draw the walls and doorways as you walked through the building, you would have to perform two tasks at the same time.

The first task is to use your flashlight to draw the walls and doorways on your paper — that’s the mapping portion of the task. The second task would be to place yourself on the paper as you moved around the building — that’s the localization portion of the task.

In other words, as you drew the walls and doorways onto your paper (the mapping portion of the task) you also had to identify your location in relation to the walls and doorways (the localization portion of the task). The robot does the same thing continuously as it moves around the facility.

That is why the continuous mapping and self-localization cycle is a critical aspect of the robot’s autonomy. The brain takes raw data from LiDAR and cameras and creates a usable map of the facility. The robot doesn’t need a pre-made map or tape lines drawn on the floor to determine how to move from the pharmacy to the patient’s bed. Once the map is created, the robot can determine the optimal path between points within the facility.

AMR Navigation System: AMR navigation systems combine mapping, localization, and path planning

An AMR navigation system is the “brains” behind an autonomous mobile robot’s ability to operate safely and efficiently in a real facility. An AMR Navigation System combines mapping, localization, and route planning to enable the AMR to move from station to station, navigate around people, and adjust when the aisle or hallway is obstructed. Without a reliable AMR Navigation System, even the most well-designed AMRs will have difficulty delivering consistent results, ensuring safe operation, and meeting required throughput.

Mapping is the beginning. The AMR Navigation System develops or references a digital model of the physical space—walls, passageways, storage lanes, and important landmark locations. Many AMRs rely on SLAM (Simultaneous Localization and Mapping) to quickly create an environment map and continuously update it over time. In environments that are constantly changing, the map will contain static elements (e.g., walls), and rules about movement within the space (e.g., one-way, speed limits, etc.).

Localization is answering the question: “Where am I currently?” The AMR Navigation System will estimate its location and heading using sensor data from multiple sources, including LiDAR, cameras, wheel encoders, and inertial measurement units.

Robust localization enables AMRs to dock precisely, arrive at specific transfer points, and navigate tight passageways without drifting into shelving or equipment. In addition to these capabilities, many sites utilize additional aids for the AMR Navigation System to improve positioning accuracy in repetitive routes, such as markers, QR codes, and/or UWB anchors.

Path Planning determines which path is taken from the point of origin (start) to the destination (goal). Typically, a Global Planner determines the most efficient path; a Local Planner enables the robot to slow down, stop, and avoid new obstacles in real time. This is particularly important in hospital and warehouse environments, where staff, carts, and pallets constantly enter and exit.

A well-tuned AMR Navigation system can balance speed, comfort, and safety to ensure the robot’s predictable behavior that staff can rely on.

Additionally, when multiple robots operate in unison, the AMR Navigation system is typically connected to a Fleet Software system that assigns tasks, prevents collisions, and manages each robot’s charging schedule. This will help reduce congestion among AMRs and ensure timely product delivery.

In general, an AMR Navigation system is necessary to make AMRs viable in real-world operating conditions; it enables accurate robot positioning, safe navigation of the workspace, and reliable task completion as the environment changes over time.

Robot Pathfinding: Robot pathfinding finds the safest and fastest route in real time

Robot Pathfinding computes the most efficient and safe path in real time by converting a map, sensor data that changes with every movement, and operating guidelines into a path decision-making process.

Robot Pathfinding assists robots in warehouse and hospital environments by enabling them to navigate narrow aisles, crowded hallways, and intersecting paths while avoiding collisions and delays.

For Autonomous Mobile Robots (AMRs), a dependable Robot Pathfinding system is crucial because their operating environment is constantly changing. People will walk in unpredictable ways, carts will enter or leave, and the route will change during the trip.

Typically, Robot Pathfinding begins with creating a Global Plan. The robot selects a route from its current location to the destination using a map generated by Simultaneous Localization and Mapping (SLAM). This global plan prioritizes efficiency: short distances, low-congestion areas, and lower risk. For AMRs, in addition to these, Global Robot Pathfinding may also account for operational rules, such as one-way lanes, no-go zones, speed limits in nurse’s station areas, and preferred routes for carrying heavy loads.

Next is Local Planning. Even the best global plan will fail the moment a pallet is blocking an aisle, or someone has stopped in the hallway. Local Robot Pathfinding converts real-time sensory input to make adjustments: slow down, yield, reroute around obstacles, or stop if there is no safe path forward. It is this local level of planning that keeps AMRs safe in both human and robot environments, where “quick” cannot be prioritized at the expense of predictable behavior.

A robot’s pathfinding is intrinsically linked to its safety. The robot will always maintain a safety perimeter; it will never get closer than the braking distance; and it will always choose a maneuver that reduces risk. (For example, it will not make a sharp turn while traveling fast; it will never pass by a person.)

In healthcare environments, the robot pathfinding can be programmed to take lower-traffic routes at night. In warehouse environments, the robot pathfinding can be programmed to optimize throughput while ensuring that forklifts and pedestrians have the right-of-way.

If multiple robots occupy the same environment, then the added layer of “fleet coordination” provides even greater functionality. Robot Pathfinding can receive signals from a Fleet Manager to manage traffic flow, eliminating deadlocks and congestion at chokepoints. This can help ensure that AMRs meet their schedules, minimize idle time, and avoid blocking critical travel paths.

Robot Pathfinding is highly measurable in practice: a robot that can find a path more quickly, travel smoothly, arrive on time, and interact safely with staff is a well-functioning robot. It is the real-time decision-making engine that enables AMRs to operate efficiently under changing conditions.

Not Just the Shortest Path: How Do AMRs Plan Routes Like Waze for Warehouses?

Using a map is one thing, but using it to navigate a busy environment is completely different. Anyone who has used a navigation app such as Google Maps or Waze understands how the concept works. An Autonomous Mobile Robot (AMR) does not simply look for the shortest path; it will find the most intelligent path available.

It takes into account factors such as digital traffic data from other robots, congested areas known to the AMR, and areas that may be temporarily closed or off-limits due to various conditions. Intelligent decision-making is essential to improving logistics with mobile robots, as it allows them to operate more effectively than creating a traffic jam.

The process of continuously calculating a path is called dynamic path planning. The word “dynamic” is very important as it means the plan is never set in stone. A hospital hallway that had been open a minute prior to the current time frame may currently be obstructed by a gurney, and a warehouse aisle may be blocked by a forklift. The AMR’s internal software operates like a live traffic reporter, providing continuous updates on its path. Real-time plan adjustment based on new sensor data and inputs from the central fleet management system is the primary function of autonomous robot warehouse routing.

Ultimately, the ability to think quickly and make decisions is what provides reliability to an AMR. When the robot encounters a blockage in its originally planned route, it does not stop but instead awaits assistance. Rather, the robot immediately computes a detour, selecting the best alternative to reach the destination.

Flexibility in adapting to unpredictable situations is critical to ensuring safe passage in human-populated environments. However, there is an additional question related to this issue: What would happen if the unforeseen barrier to the robot’s movement is not a box, but a human who steps directly in front of a 300-pound robot?

Autonomous Navigation: Autonomous navigation lets robots plan and adjust routes independently

Autonomous navigation is the ability of a robot to make its own decisions about which way it should go to accomplish a task, and how it will navigate around objects while doing this. Autonomous navigation allows the robot to avoid following a pre-programmed path with specific waypoints (e.g., a warehouse) or being controlled directly from a remote location (e.g., a car).

In places like warehouses, hospitals, and manufacturing facilities, the need for autonomous navigation is most apparent due to the presence of many people, carts, and moving parts (such as automatic sliding doors) that can constantly change the optimal path. For Autonomous Mobile Robots (AMRs), autonomous navigation is the critical capability that turns “moving” into “usable”.

A general autonomous navigation system consists of four main components: perception, localization, planning, and control. Perception refers to the sensors the robot uses to determine its surroundings and identify potential obstacles. These sensors include, but are not limited to, lidar, cameras, ultrasonic sensors, wheel encoders, and inertial measurement units (IMUs). Localization is the process of determining a robot’s position on a map of the area.

Many localization methods use Simultaneous Localization And Mapping (SLAM), enabling the robot to continuously update its map of the environment and maintain accurate positioning even as the environment changes. Once the robot’s position and surrounding obstacles are determined, the Autonomous Navigation system computes the optimal route to the destination and generates the necessary control inputs to execute it safely.

The true value of autonomous navigation is realized in situations where unexpected events occur. A common example is a robot slowing down, yielding to traffic, finding an alternative route, or waiting until the obstacle has moved before continuing. Autonomous navigation systems are particularly important in applications requiring AMRs to deliver high service levels to customers during periods of high usage (e.g., peak hours, shift changes), construction, or other unforeseen disruptions to normal operations.

Autonomous navigation systems can also enforce customer-specific rules (e.g., geofencing and speed limits) and optimize routing based on load characteristics (e.g., heavy loads prefer certain paths).

Autonomous Navigation collaborates with Fleet Management in Multi-Robot Systems. The Fleet Management Layer enables Task Assignment and reduces Congestion, while Local Decision Making (such as Passing, Merging, and Safe Stopping) is performed by each robot. The collaboration of these two layers enables the Avoidance of Deadlock in AMRs and improves overall throughput, but will not create an Overly Cautious or Overly Aggressive Individual Robot.

Conservative Braking Distances, Obstacle Classification, Emergency Stopping, and Predictable Behavior towards People enable Safety within Autonomous Navigation. Most AMRs utilize Audible/Visual Signals to indicate Intent and therefore provide Smoother Interactions with Staff.

Ultimately, Autonomous Navigation enables consistent Indoor Transportation: they can find a Route, react to real-world surprises, and Complete Missions Reliably — without Continuous Human Supervision.

What Happens When a Person Steps in Front of a 300-Pound Robot?

Fortunately, the answer is: not too much. The robot merely comes to a complete halt. Before the robot can come anywhere near your location, the robot’s many sensors (including the always-rotating LiDAR and 3D camera) will likely detect you.

The sensors form a protective bubble around the robot, which you cannot breach until the robot has completely stopped. Once you, as a person, or anything else, breaches that bubble, the AMR will automatically slow to a smooth stop using its primary safety protocols. In some respects, the emergency braking features in today’s vehicles are similar, but in a warehouse or hospital setting, the AMR is often far more sensitive.

However, the robot’s continuous obstacle scanning does more than merely prevent collisions. The robot’s “brain” can dynamically avoid obstacles. This means the robot is intelligent enough to distinguish between a stationary box and a person moving toward it. The robot’s “brain” will analyze the object’s approach speed and trajectory to determine whether it is a person and, if so, where the person is headed. Rather than simply stopping and obstructing the hallway, the robot typically recalculates a path around the person and moves aside to allow them to continue their journey.

In addition to being smart, these reflexes are a fundamental component of the robot’s design and are governed by numerous stringent medical and manufacturing safety regulations and guidelines. Layers upon layers of safety, from sophisticated software to actual emergency-stop buttons located on the robot itself, protect both humans and the robots themselves while working together in the same area. A nurse, for example, can easily walk by an AMR without giving it a second thought, knowing that the robot will not begin to move again until the nurse is no longer in its immediate vicinity.

The reliable one-on-one safety afforded to both humans and robots enables collaboration. However, how does this type of reliability scale? How does one prevent a robot traffic jam in a bustling warehouse?

How Do You Prevent a Robot Traffic Jam in a Busy Warehouse?

Fleet management software is essentially a “brain” that connects all of the robots on a warehouse floor, much like the air traffic control tower oversees the movement of airplanes across the country. The central platform tracks each robot’s location, remaining power, and the specific task to be completed. Thus, when a new task becomes available, such as picking up a specific product for an order, the software will determine which robot is in the correct position and has sufficient power to complete it (similar to how Uber matches drivers with passengers).

The software’s ultimate goal is to keep robots moving efficiently throughout the warehouse, ensuring orders are fulfilled quickly and effectively. Each robot operates independently, but fleet management software enables them to coordinate their actions to avoid congestion or bottlenecks in the warehouse. For example, while an individual robot may successfully avoid a person who suddenly enters its path, the fleet management software will prevent multiple robots from entering the same narrow aisle simultaneously. In addition, the software will plan each robot’s route, allowing some robots to temporarily stop to allow others to pass.

Thus, fleet management software enables high coordination among robots, much like traffic lights and road signs coordinate the flow of automobiles in urban areas. The need for such coordination is particularly important in busy warehouses, but it is also common in many other settings. For example, a hospital may require coordinating the activities of medical staff, patients, equipment, etc., to provide safe, effective, and timely care.

Warehouse Aisles vs. Hospital Hallways: Why Each Environment Is a Unique Challenge

While the fundamental technologies for sensing and locomotion are the same, the “personality” and behavior of an Autonomous Mobile Robot (AMR) can be drastically modified by its operating environment. For example, an AMR optimized for a large distribution center would likely be disastrous in a hospital setting, and vice versa. This is not a case of “one size fits all.” The software used to control the AMR must be customized to the unique rhythms and rules of its environment. It may be thought of as training a driver to navigate both a highway and a quiet school zone.

A warehouse environment is primarily concerned with maximizing speed and efficiency; such environments are typically large, well-structured, and designed for machine operation. In this environment, the AMR’s primary objectives are to quickly and efficiently locate and/or move goods along the long, predictable warehouse aisles.

The greatest obstacles to the operation of an AMR in this environment will be avoiding collisions with other mobile robots and equipment within the very large warehouse. The Fleet Manager functions as a highway traffic controller, determining the most efficient and safest path for each AMR at any given time, while maintaining high speeds to meet the warehouse’s very demanding logistics schedules.

On the other hand, a hospital hallway is the antithesis of a warehouse environment. It is a highly dynamic, unpredictable area populated by what is certainly more valuable than boxes – people. In addition to doctors, nurses, patients, and visitors being in constant motion, many times under pressure or in emergency/sensitive situations.

Therefore, in a hospital environment, the AMR’s top priority shifts dramatically from speed to safety and awareness of others. The AMR must be programmed to be extremely cautious, yielding to people and providing ample clearance to avoid collisions, much like a polite pedestrian navigating a crowded sidewalk.

It is also at this point that the ability to customize/modify the AMR navigation technology is demonstrated. As previously stated, the AMR’s programming is modified to enable it to develop a different personality/behavioral profile. For example, a hospital AMR will be able to achieve a significantly slower top speed, softer acceleration, and greater obstacle-detection sensitivity to ensure it never appears intimidating. Additionally, the AMR is programmed to prefer less-traveled paths (even if they require longer travel times) to minimize disruption.

Thus, one is a sprinter focused on crossing the finish line as quickly as possible; the other is a helpful assistant designed to assist without interfering with either the AMR or those traveling in the area.

The Future Is Here: AMRs Aren’t Just Carts, They’re Smart Teammates

“An AMR’s laser ‘eyes’ and camera ‘senses’ create a ‘map,’ while its digital ‘brain’ provides an intelligent pathway and quickly responds to obstacles through its fast reflexes. This formerly ‘black box’ has been transformed into a clearly defined process with three steps: sense, think, act.

This technology offers a window into what the workplace will look like in the years ahead. Videos of busy warehouse operations or stories about hospitals using this technology help you differentiate the new, intelligent machines from older, basic equipment. These machines do much more than move packages and medical supplies; they advance a vision of the workplace.

That vision is based on enabling nurses to deliver one-on-one patient care during hospital stays and ensuring that critical orders arrive on time. Ultimately, these machines will not be replacing people; they will help eliminate the boring, faraway, and difficult tasks so we can concentrate on the relationships that make a difference.”

Conclusion

Navigation by AMRs occurs through a process of continuous (1) sensing of their surroundings; (2) locating themselves within those surroundings; (3) planning their next course of action; and (4) adaptation to changing situations – all of which transform difficult-to-navigate indoor environments into reliable and safe paths for AMRs to follow.

Through LiDAR, camera, and sensor-fusion technologies, AMRs develop a detailed understanding of objects and people located near them – including but not limited to walls, shelves, equipment, etc. By using SLAM technology to determine both where they are located, and how the space around them is laid out at the same time – even as the conditions of the environment around them continue to evolve.

AMRs create a base upon which they can perform Dynamic Path Planning to find the most efficient route(s) through the facility and/or hospital at hand – and then instantly re-route if needed due to blockage of an aisle, crowding of a hallway, or a change in priorities of tasks assigned to the AMR.

In addition to the above capabilities, AMR Navigation Systems are specifically designed for the environments in which they operate. A multi-level safety approach is built into the systems and includes early warning, gentle braking, and obstacle avoidance, enabling the robots to operate safely in the confined spaces of human environments. The ability to manage fleets of robots is another benefit of the systems, as they enable coordinated traffic flow, prevent bottlenecks, and assign the appropriate robot to each required task.

The end result of these capabilities is practical autonomy for warehouse AMRs, leading to faster warehouse fulfillment, more consistent and predictable internal logistics, and, in hospitals, more time back for clinical personnel. As navigation software sophistication increases, AMRs will be viewed as increasingly capable team members in day-to-day operations.

FAQs

- How do AMRs “know” where they are inside a warehouse or hospital?

AMRs localize using SLAM techniques that fuse LiDAR and/or camera data with odometry and inertial sensor readings to determine their position at a given moment within a map. - What sensors do AMRs use to detect people and obstacles?

Almost all AMRs use LiDAR and 2D/3D cameras and often incorporate additional sensors, such as ultrasonic and bump sensors, to detect potential obstacles and maintain a safe stopping distance. - How do AMRs choose routes and avoid traffic jams?

Using dynamic path planning, these robots can adjust their route in real time when they encounter blockages, and, through fleet management software, multiple robots can be coordinated to avoid congestion and deadlocks. - Are AMRs safe to operate around staff, patients, and visitors?

Yes—AMRs are built with multi-layered safety features, including speed limits, obstacle avoidance, emergency stops, and rules of behavior (i.e., yielding in hallways) for each robot. - Why do AMRs behave differently in warehouses versus hospitals?

Warehouse environments prioritize speed and throughput, whereas hospital environments prioritize cautious, human-aware navigation—faster or slower speeds, larger clearance, and tighter zone restrictions.

Comments 3