Many small businesses are always looking for new ways to increase productivity while keeping costs down. Collaborative robots, or cobots, have become increasingly popular as safe, affordable tools that enable small businesses to create more efficient processes. This article explains how cobots for small businesses can improve efficiency, reduce employee workload, and drive growth.

Sick of the people calling in to miss their turn at doing the tedious, uninteresting thing on your assembly line? Before posting yet another boring job ad, you may have an alternative solution to this problem-one which never gets sick, gets bored, or quits after 6 months to go back to school and become a real engineer (or whatever).

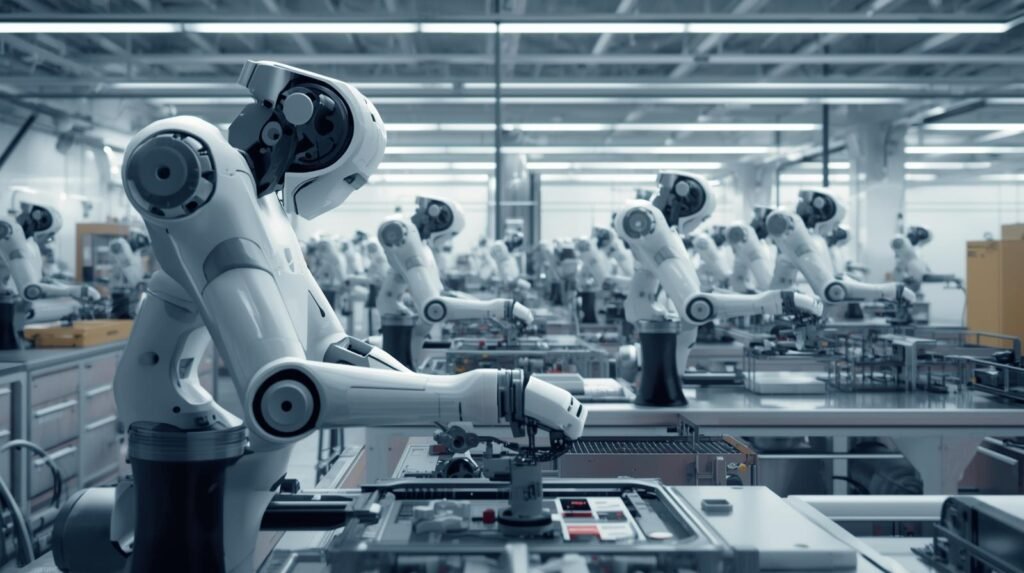

The history of automation has always been defined by large, spark-spewing machines located in large manufacturing facilities, and thus far beyond the reach of nearly all other companies. A new class of automation, however, is now allowing businesses to build their own future of the factory, but today, Collaborative Robots, or “Cobots”.

These cobot systems are being developed to meet the specific needs of small- and medium-sized businesses. They allow less interesting, monotonous tasks to be handled by cobots, freeing your talented employees to focus on more interesting, meaningful work. It is not about creating a factory of the future-it is about improving productivity in your business today.

Summary

“Cobots in Small Businesses: Powerful & Practical Why It Matters” shows that collaborative robots (cobots) provide a reasonable opportunity for small teams to automate without the costs associated with large industrial robots. Cobots have been designed to work alongside humans in an environment where humans make all decision-making, quality checking, and exception handling; and the cobot is used to do the heavy lifting on repetitive, accurate, and/or dangerous tasks such as labeling, packaging, pick-and-place, light assembly, machine tending, and low-level inspections. This article outlines several reasons why cobots are a valuable asset for small businesses facing labor shortages, volatile demand, and ongoing product changes.

These include maintaining stable cycle times, reducing error and rework, and moving them to the next area of need as your operation evolves. This article also addresses the business side of cost-effective automation and suggests a pilot-based first approach to implementing cobots, measuring return on investment through throughput, scrap, and downtime metrics, and lower integration needs when compared to caged robots.

Finally, this article ties cobots to other forms of efficiency tools including digital work instructions, inventory tracking and standardized workflows, showing that when you combine physical and process automation, small businesses will increase their ability to produce products, maintain profit margins, create better working conditions for employees, and compete with larger organizations with out having to hire staff at the same rate of growth.

This article suggests that the best way to begin to use cobots in your organization would be to start with a single task that has a consistent volume of production, involve your operators in the process, establish the basic safety and maintenance procedures, and then use the results from these initial projects as the basis for expanding automation in your organization on a project-by-project basis.

What’s a ‘Cobot’? Think Power Tool, Not a Caged Machine

Cobots are made to remove the barrier between people and robot assistance.

The design difference centers on safety. The sensor technology inside the cobot is designed to stop if a person makes accidental contact with the cobot (it will slow or stop its movement). Safety enclosures are no longer required because the cobot’s sensor technology enables safe integration into the same workstation as people.

Think of a cobot as an extremely flexible and versatile power tool; rather than replacing employees as new hires, they have the capability to allow existing employees to shift repetitive, laborious, or monotonous aspects of their jobs to the cobot, freeing time to concentrate on aspects of their job that utilize their skills, such as quality assurance or problem-solving. This has the potential to make your entire business more productive.

Cobots for Small Businesses: A collaborative robot assisting a small business worker in a shared workspace

Cobots for Small Businesses are collaborative robots designed to work alongside people and take on repetitive, precise, or physically demanding tasks. For many business owners, the most attractive aspect of Cobots for Small Businesses is their practical benefits: faster throughput, lower error rates, and consistent quality—without hiring large teams or rebuilding their entire workflows.

Unlike other industrial robots that require cage enclosures and extensive integration, Cobots for Small Businesses are generally easier to implement and reassign. Most units will have capabilities to package, place parts (pick-and-place), tend machines, assemble lightweight components, label products, and inspect items for defects. The versatility in function has significant value to small manufacturers who produce in low batch quantities, experience fluctuating seasonal demand, or create multiple product lines that may change rapidly. When a manufacturer experiences an operational constraint (bottleneck) it is much easier to transfer the Cobot to the constraint rather than design a new manufacturing process.

A final reason that Cobots for Small Businesses are attractive as a first step toward automation is the lower cost. Cobots for Small Businesses generally require less floor space, fewer safety barriers, and less setup time. Many businesses begin by deploying a single cobot on a single task and tracking cycle time savings and scrap reduction. If those metrics indicate a positive Return On Investment (ROI), the business expands its use of cobots. Using this incremental approach reduces risk and helps maintain cash flow—especially for smaller firms.

The Cobots for Small Business solutions also help address labor issues. If your business is struggling to find qualified candidates or retain staff for repetitive or physically demanding roles, a cobot may be able to take on less preferred duties, allowing employees to focus on delivering value through customer service, troubleshooting, product customization, and product quality. Through this method, Cobots for Small Businesses will increase employee satisfaction, protect output, and deliver products to customers on time.

To receive maximum benefit from Cobots for Small Businesses, limit your initial application to a single well-defined use case; i.e., consistent production parts, measurable metrics of success, and a continuous repetitive process. Also, provide employees with minimal training, plan for regular, simple equipment maintenance, and design the environment to ensure a safe work area. By taking a careful, deliberate approach to implementing Cobots for Small Businesses, they can become an efficient, cost-effective solution that enhances productivity and helps them remain competitive.

Small Business Automation: Automation helps small businesses scale without hiring more staff

Small Business Automation increases efficiency and consistency while giving the owner flexibility in adding staff. As Small Business Automation handles all routine operations through software and machines, employees are able to service their customers, create quality products, and solve problems rather than just completing repetitive steps. For many businesses, demand will grow at a much faster pace than it takes to recruit, train, and supervise new employees.

Using Cobots for Small Businesses is one of the best ways for small business owners to get started with automating routine, predictable physical tasks. Cobots for Small Businesses can complete tasks such as packing and labeling, machine tending, light assembly, kitting, and inspections – all in the same space as your employees. Adding Small Business Automation tools such as Digital Work Orders, Barcode Scanning, and Inventory Alerts will compound the gains made in improving the process flow from an Order to a Shipment: fewer handoffs, less rework, and improved flow.

As the advantages of scaling come from converting Tribal Knowledge into Repeatable Processes, Small Business Automation ensures that there is standardization in the generation of quotes, scheduling of jobs, and flagging of exceptions, so that no matter who the employee performing the task may be, the performance does not rely on that one “go to” person. The use of Cobots for Small Businesses helps to stabilize cycle time and reduce variability. Cobots do not call in sick and perform the same motion every time, which helps meet tight deadlines as volumes increase.

Another area where small business automation helps is cost control. Small Business Automation decreases “hidden” labor related to coordinating, status updates, duplicate entries, and other manual follow-up. Cobots for small businesses reduce waste from handling errors and fatigue. As the needs of your product line evolve, Cobots for Small Businesses can be assigned to different bottlenecks to minimize the loss of your initial investment while still allowing flexibility to grow your business.

Start by mapping one process that has a high number of delays and/or errors, and begin automating the smallest segment that will produce a measurable improvement. Train employees to oversee the automated process, identify issues, and make improvements as necessary. Using data will enable you to continually improve the efficiency of the automated process. If you select the correct first project for the use of either Small Business Automation or Cobots for Small Businesses, it will assist you in scaling capacity, protecting margins, and growing your business without hiring additional employees for each new customer.

Cobots Don’t Replace Your Best People—They Empower Them

The biggest concern for business owners is not cost; it is the impact of automation on the workforce. However, with the advent of cobots, the potential loss of value to employees is the opposite. A cobot should be viewed as a powerful tool capable of performing dull, dirty, and dangerous tasks that drive employee burnout and high turnover. Thus, using cobots for solving labor shortages, rather than replacing people, makes the jobs offered to your employees more appealing and sustainable.

When you enable cobots to perform tedious tasks typically required of employees, you create opportunities for employees to leverage their uniquely human skills, such as problem-solving, quality control, and adaptability to new situations. As a good example, the ability to use cobots in welding is apparent when you think about your best welder. If they spend all day doing thousands of repetitive tack welds, then why not let a cobot do those same repetitive welds with perfection? Now, your skilled welder can focus on assembling frames and finalizing products-the high-value processes that require the skill, expertise, and experience of your welder.

As a result of this shift in responsibility, employees can begin developing the skills to perform higher-level functions. The person who previously manually loaded parts into a machine can now be trained to be the cobot’s operator and educator. Once trained, they can assist with setting up new tasks, troubleshooting problems, and managing the efficiency of the cobot-based process. In this way, they can transition from manual labor to operating and maintaining automated systems and acquire valuable new skills that enhance their job satisfaction and security. Ultimately, this transformation of a stressful job into a technically challenging and fulfilling career path increases employee motivation and productivity.

Cobot Benefits: Cobots improve productivity while keeping humans in control

Cobot benefits are most apparent when an automated system increases production (output) without eliminating workers from the process. Many small business owners will find that cobots for small businesses represent a compromise on this point; they represent a “second pair of hands” (reliable) that perform the repetitive actions while the employee is responsible for decision-making, adjusting the process, etc., as well as evaluating the quality of the final product.

Two primary Cobot Benefits include increasing productivity without reducing flexibility. Cobots for small businesses operate in continuous cycles for tasks such as pick-and-place, packaging, labeling, and machine tending, while an employee oversees the multi-step task and intervenes only when necessary. This approach preserves employee control over priorities and exceptions, rather than automating the entire operation within a single, inflexible system.

A second area where Cobot Benefits emerge involves consistency. Cobots for small businesses consistently repeat the same motion, reducing the risk of defects from fatigue, rushed handling, and similar causes. As long as the employee has established the standards and is verifying the results, this approach provides consistent throughput while maintaining human judgment on what constitutes a “good” outcome.

Safety and ergonomics are also among the benefits of cobots. For example, Cobots for Small Businesses can perform an endless series of awkward lifts, extended reaches, and repetitive shoulder or wrist motions that cause worker fatigue. By having workers stay at their stations while moving into roles that carry lower injury risk (e.g., setup, inspection, replenishment, and process improvement), rather than performing physically demanding tasks all day, workers can focus on the value-added aspects of the production process.

In addition to safety and ergonomic Cobot benefits, there are also financial Cobot benefits. The nature of Cobots for Small Businesses lends itself to being a phased or staged investment. Start by implementing a Cobot for a single defined task that has a high amount of wasted time, material waste, or other inefficiencies; once you have captured the time savings and reduced the waste associated with this initial task, then implement additional tasks that also contribute to your bottom line.

Additionally, because Cobots for Small Businesses can be redeployed, the same unit can support multiple products or meet seasonal demand without requiring a redesign of the entire system. To take advantage of both the financial and physical safety and ergonomic Cobot benefits, select a stable first task, develop measurable criteria to evaluate its success (e.g., cycle time, defect rate, downtime), and teach your operators how to modify and update programs safely.

Using a similar approach to establishing a pilot program with clear ownership and focusing on a limited number of initial tasks and operations will allow your company to improve productivity through the use of Cobots for Small Businesses while still maintaining control over the production process. This represents the most practical benefit of using Cobots for Small Businesses.

Business Efficiency Tools: Cobots act as efficiency tools that streamline daily operations

Business efficiency tools help small businesses to accomplish more with fewer resources. As one of the best business efficiency tools, cobots are increasingly considered by small business owners. Many small business owners view Cobots for Small Businesses as flexible assistants that save time on time-consuming repetitive tasks; however, people remain in charge of decision-making, quality control, and customer satisfaction. When used properly, Business Efficiency Tools enable small businesses to operate more efficiently day-to-day without requiring a complete overhaul.

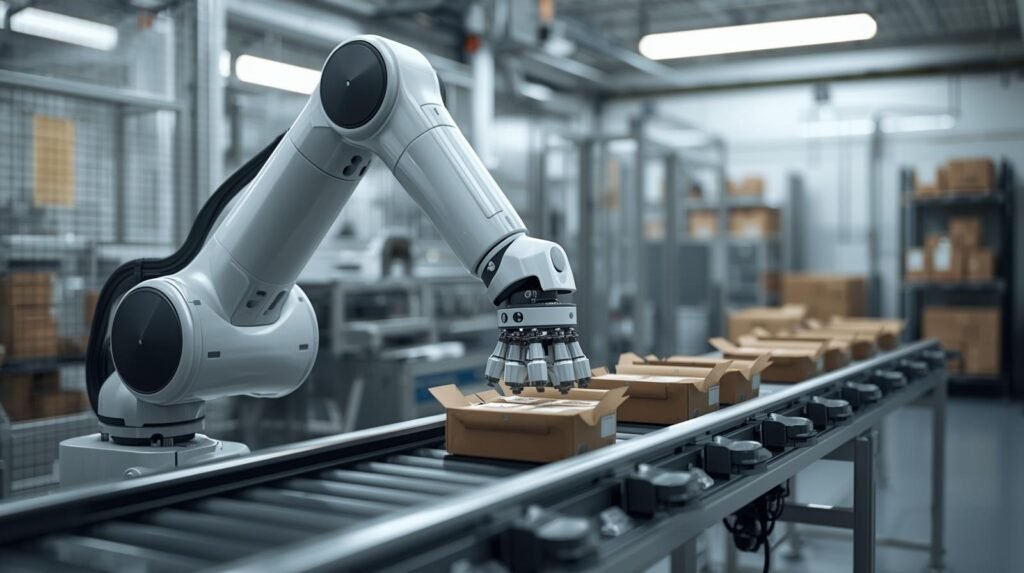

Cobots for small businesses can be used in production and fulfillment to automate routine tasks such as pick-and-place, packaging, labeling, kitting, and light inspection, providing stability and efficiency. These tasks are generally repeatable, making them ideal for use with Business Efficiency Tools that eliminate stop-and-go work and maintain consistent flow to maximize production. Consistently maintaining a steady production flow and minimizing bottlenecks and downtime from continuous task switching are the primary benefits of using Cobots for Small Businesses as Business Efficiency Tools.

Cobots’ ability to perform repetitive tasks consistently is also why they are viewed as effective Business Efficiency Tools. Since Cobots for Small Businesses perform all of their cycles in the exact same manner, it is possible to minimize errors that result from manual handling (i.e., mislabels and minor defects) and the subsequent rework required to correct those issues. By having an operator monitor for exceptions and verify results, Cobots for Small Businesses increase process reliability while keeping human judgment at the core. This combination is the key to converting automation into everyday Business Efficiency Tools rather than a rigid automated system.

Cobots provide labor efficiency. Cobots for Small Businesses can perform the most physically demanding or monotonous tasks, allowing employees to focus on higher-value work, such as setting up machines, troubleshooting, checking product quality, and communicating with customers. This allows businesses to become less reactive in their daily work, which is another key element of successful Business Efficiency tools.

The first step in implementing cobots as Business Efficiency tools is to select a stable task and define how it will be measured (e.g., cycle time, defects, downtime, on-time delivery). The pilot should precede training operators and refining handoffs; specifically, the way parts are presented to the cobot, the workstation layout, and the simple safety routines. Once you have built confidence with the use of the cobot for the first task, you may then redeploy the cobot to your second constraint and continue to add business efficiency tools and expand the reach of these tools over time.

Cobots for Small Businesses are effective at improving labor efficiency by streamlining repetitive process elements, protecting process consistency, and enabling small business teams to grow day-to-day execution capabilities—precisely what Business Efficiency tools are intended to do.

4 Everyday Tasks a Cobot Can Take Over in Your Business Today

How a cobot functions depends completely upon what task(s) you assign to it. When a cobot has a different end-effector (hand), it can perform many different types of jobs. That is why a single cobot can handle a wide variety of jobs that would otherwise be bottlenecks in a small operation. Here are four of the most common and most valuable uses for cobs in small business operations:

1. Packaging & Palletizing: The cobot will continuously pick up finished goods, place them into packages, and package those packages into shipping pallets. It is well-suited to repetitive tasks at the end of a production line that are difficult to staff.

2. Machine Tending: Machine tending involves the cobot loading raw materials into a machine (i.e., a CNC milling machine or injection molding machine) and unloading finished parts from that same machine. This will allow your expensive equipment to run continuously, even during employee breaks or off-hours.

3. Quality Control Inspection: Using either a camera or sensor attached to the cobot, it can inspect every product for defects, resulting in the guarantee that all defective products are never shipped to your customers.

4. Assembly & Dispensing: The cobot can apply precise torque to fasteners, dispense adhesive in the correct amount, or complete small assembly-type tasks requiring consistent, repetitive movement.

The reason cobs are so versatile is due to the interchangeable nature of the end-effector, also known as the EOAT (End-of-Arm Tooling). The EOAT is the “hand” of the cobot and is the part that is swapped out to complete a specific task. For example, if you want a cobot to pick up boxes, you could attach a simple two-finger gripper to the EOAT. If you wanted to use the cobot to lift flat sheets, you would attach a vacuum cup to the EOAT. If you wanted the cobot to assemble something using a screwdriver, you could attach a screwdriver to the EOAT.

Because the EOAT can be easily changed, a cobot is not a one-trick pony; rather, a cobot is an asset that can be adapted as your company expands and your requirements evolve. Additionally, you do not need an engineering degree to implement a cobot. In fact, training a cobot to perform a new task is typically much easier than expected.

Cobots in Industry: Cobots are transforming industries of all sizes, including small enterprises

The development of Cobots in Industry is changing how work is executed, making automation accessible to companies that need adaptability rather than those requiring mass-production capacity. Cobots in Industry are used in Electronics, Food and Beverage, Metalworking, Packaging, Logistics, and Niche Manufacturing, where product variation is high and batch sizes are too small to justify large-scale automation systems. The relevance of Cobots for Small Business Owners is clear. Cobots enable small business teams to achieve the same level of productivity without requiring a fully automated plant.

One of the major factors driving the growth of Cobots in Industry is their Collaborative Design. Cobots for Small Businesses can work collaboratively with individuals at the workstation to perform functions such as Pick-and-Place, Machine Tending, Light Assembly, Palletizing, and Basic Inspection. When Cobots for Small Businesses are used in this method, human team members continue to make critical decisions related to Setup Changes, Quality Checks, and Exception Handling, while the Cobots provide consistent, repeatable motion.

Cobots in Industry also help address labor constraints. Many small businesses face challenges hiring for the most undesirable and physically demanding tasks. Cobots for Small Businesses enable these small businesses to automate the most undesirable tasks, allowing employees to focus on higher-value work such as customization, customer communication, troubleshooting, and Process Improvement. In fact, Cobots in industry typically do not displace teams; they help maintain production pace.

Another benefit of Cobots in Industry is increased standardization, as Cobots for Small Businesses improve consistent performance and reduce variability from shift to shift, thereby lowering defect and rework rates. Consistent production increases competitiveness by enabling faster, higher-quality product delivery. In addition, Cobots in Industry are becoming an increasing expectation of customers who desire reliable delivery and traceability throughout their manufacturing process – both of which can be supported by Cobots in Industry.

Cobots in industry offer financial benefits because they can be implemented incrementally. Typically, Cobots for Small Businesses are used to perform a single defined task. Once a clear ROI is demonstrated through increased throughput, reduced scrap, and reduced delays, Cobots for Small Businesses can move to the next bottleneck. This allows the cobot’s cost to be amortized over many years.

In summary, Cobots in Industry are changing how all industries operate, and Cobots for Small Businesses are the most obvious example of practical automation that scales production capacity while maintaining human control.

Cost-Effective Automation: Cobots offer affordable automation without high upfront costs

Cobots for Small Businesses are expanding beyond large factory settings, thanks to their cost-effective automation capabilities. In terms of cost-effective automation, this means increasing production volume without significant capital investments, extended production shutdowns, or expensive custom-designed solutions. This is where Cobots for Small Business deliver as a viable solution for practical, phased automation, allowing businesses to expand automation only when the results warrant it.

One of the most valuable aspects of cost-effective Cobot automation for Small Businesses is the ability to start small. The first step for small businesses with cobots is to automate a repetitive process, such as packaging, labeling, pick-and-place, machine tending, or light assembly. Once a process is automated, the business can immediately measure the savings. If the business takes a phased approach to cost-effective automation, then the risks associated with implementing an automation system are greatly reduced. Instead of making a business-wide decision based on a full redesign of an operation, the business can implement automation solutions incrementally, reducing overall automation project costs.

Another important aspect of cost-effective Cobot automation for Small Businesses is the lower level of integration required compared to traditional industrial robots. Traditional industrial robots often require extensive guarding, safety equipment, and specialized programming. Additionally, traditional industrial robots often require a dedicated area for installation and use. As a result, Cobots for Small Businesses are generally simpler to install and reconfigure, reducing the time and resources required to get the robot operational and leading to faster ROI and less lost revenue when profit margins are tight.

Another advantage of cost-effective automation is the flexibility you retain throughout your automation investment. Cobots for Small Businesses can be moved around the shop as product lines are changed—from a packaging application in one quarter to a machine tending application in the next. Since the cobot can move within your workflow constraints, rather than sit idle and be used for an obsolete task, this redeployment creates a more resilient, Cost-Effective Automation solution.

The cost savings from Quality Improvements add to the Cost-Effective Automation argument. The consistent motion and repeated placement provided by Cobots for Small Businesses eliminate costly errors, reduce scrap and rework, and save employee time and labor. As employees continue to monitor quality and address any issues that arise, the steady flow of production from Cobots for Small Businesses will help them meet customer expectations and align processes accordingly. Therefore, using a human to control the cobot keeps the Cost-Effective Automation flexible rather than rigid.

To get the most out of your Cost-Effective Automation implementation, select a reliable process, establish well-defined metrics (cycle time, defects, downtime), and provide your operators with training on how to monitor and safely modify their use of the cobot. By establishing a defined pilot program, you will find that Cobots for Small Businesses will produce Cost-Effective Automation solutions that increase both your throughput and quality at no high upfront cost.

How Much Does a Collaborative Robot Cost? A Practical Budgeting Guide

It’s impossible to avoid this big question: What is the cost of a Collaborative Robot? A high-quality entry-level Cobot Arm from a well-established manufacturer will likely have a base price of $25,000 to $45,000. This is the core of what makes up the technology – the intelligent, safe, flexible and programmable arm that is the basis of your automated process.

This price point has made this technology accessible to far more than large corporations. However, there are other costs associated with purchasing a Cobot. In order to do something with a Cobot, you need to attach a “hand”, called an End Effector (such as a Gripper or Suction Cup) to the arm. Additionally, depending on the requirements of your specific application, you may also need a stand or some type of fixture to hold the arm in position.

When you factor in the cost of both the robot arm and all of the additional items needed to get the system up and running, the typical total investment for a relatively straightforward application will be between $35,000 to $60,000. This is the “all in” amount, which is the best estimate to use when initially planning your budget.

Although that may seem like a lot of money at first glance, the key is to view this from a business perspective. For many small businesses, the one-time purchase of this equipment is equivalent to the full-loaded annual cost of one employee. While an employee will eventually leave, take vacation days, etc., a Cobot is a fixed asset you own. It runs 24 hours per day, 7 days a week, takes no breaks, performs the same tasks with the same accuracy and reliability every single time, and never calls in sick. All of this reframes the investment and leads to the ultimate question: Is it Worth It?

Is It Worth It? How to Quickly Calculate Your Cobot’s Payback Period

Calculating the Payback Period — and thus determining whether the “Is It Worth It?” question has a positive answer — is based solely upon quantifying your Return on Investment (ROI) as a business owner. There is no better way to illustrate this than simply calculating the Payback Period, which is the amount of time it will take for your company to recover the entire cost of the cobot system (including all costs) via reduced expenses from labor (i.e., saved money).

This is a very simple process. Simply take the total cost of the cobot system and divide it by the total cost of labor per year for the specific task(s) being completed by the cobot. If the total cost of the cobot system was $45,000 and the total cost of labor per year for the task(s) being performed by the cobot was $30,000, then your Payback Period would be only 1.5 years ($45,000 / $30,000). Therefore, after 18 months, the cobot is producing pure profit for your business.

However, the simple calculation outlined above does not tell the whole story. The actual Return on Investment (ROI), and therefore the actual benefit of a cobot, includes more than just the cost savings of the labor you are saving.

The true ROI includes the increased revenue from the increased volume of products produced (due to a cobot operating around the clock at consistent levels); the reduction in material waste due to a cobot reducing the number of human errors; and other cost reductions that may occur as a result of using a cobot (e.g., fewer overtime hours). As such, when you calculate the ROI of a cobot and factor in the increased revenue and cost savings, the financial argument for purchasing a cobot becomes significantly more compelling.

As a result of including these additional benefits of a cobot in the ROI calculation, many small manufacturers, as well as those who produce low volumes, have a payback on their cobot within 12 to 18 months, providing one of the most immediate and impactful investments available today. However, the true value of using a cobot extends far beyond the financial impact on your business.

‘Easy to Program’ Isn’t a Gimmick: How You Can ‘Teach’ a Cobot in an Afternoon

The image most people have of “robot programming” is writing complex code in front of a blank computer screen. But programming for cobots works much differently. Most cobots are programmed using hand-guiding, where you press a button to release the robot arm’s brake and then manually guide it along the desired path. You essentially instruct the cobot how to perform a task by physically moving the arm to demonstrate where to pick up an object, how to transport it, and where to place it.

You pair this manual instruction with a simple hand-held control device called a teach pendant (think ruggedized version of an iPad). The teach pendant has a user-friendly interface on which you can input specific points, such as the location at which the robot is hovering above a box, and “save” that location by tapping a button. In addition to saving locations, you can program the cobot to perform simple actions, such as closing a gripper and waiting for a few seconds.

The combination of manually demonstrating a motion and a visually driven “tap-and-go” interface makes the cobot easy to program, and therefore suitable for users who may be inexperienced programmers.

The ease of programming these cobots significantly reduces implementation time in a small manufacturing facility or workshop. Cobots can be integrated into many applications within hours, whereas traditional automation systems may require months to fully integrate. For example, implementing a basic cobot to load parts into a shipping box typically takes no more than one day, enabling your new tool to begin generating revenue and improving your bottom line almost immediately. The rapid return on investment (ROI) means that you will realize a significant ROI in a very short period of time.

Is Your Business a Good Fit for a Cobot? A 5-Point Checklist

To help determine whether a Collaborative Robot (Cobot) is right for your application, use these five basic questions.

1. Do you have simple, repetitive tasks your employees do not like doing?

2. Are you experiencing labor shortages or excessive employee turnover on particular jobs?

3. Does manual error in boring, repetitive work cause loss of revenue due to errors and/or waste?

4. Would increasing your production rate be beneficial, but you do not have enough floor space available to accommodate more equipment?

5. Are your higher-skilled employees performing lower-skilled tasks?

If you answer “yes” to 2 or more of these questions, you’ve identified an area where a Cobot could create value. The next step is not to begin researching different types/models/prices of Cobots — it’s much easier than that. Simply choose one of those jobs and create a detailed, step-by-step process of how to complete the task: How long will this job take? What are all of the steps involved? That single piece of paper represents the initial, tangible actions you’ll take to implement a Cobot, turning a vague concept into something actionable.

Conclusion

Small businesses can compete in a fast-paced, consistent, and flexible marketplace with cobots that handle repetitive and dangerous tasks, allowing employees to focus on quality, troubleshooting, and decision-making in each process. For small business owners, the most valuable benefit of using cobots is the ability to decide how the job gets done. This allows production rates and error rates to increase without sacrificing the adaptability customers have come to expect from small businesses.

Cobots also enable companies to automate processes gradually. A company can introduce a single-task cobot and measure it against specific performance metrics before deciding whether to expand its use. In addition, cobots are generally easy to redeploy, so once a company has invested in a cobot, the equipment remains useful even if the company’s product mix or customer demand changes, helping automation keep pace with the bottleneck without requiring a complete redesign of the manufacturing floor.

In summary, cobots are effective and practical because they improve productivity, safety, and consistency, and fit the constraints of most small businesses (space, staff, budget). Therefore, start a focused pilot program, include the people who perform the work, and scale based on the results achieved. If implemented correctly, cobots will provide a sustained competitive advantage, enabling small businesses to grow without sacrificing what made them successful.

FAQs

- What is a cobot, and how is it different from a traditional industrial robot?

A collaborative robot, also referred to as a “cobot”, is engineered to operate next to humans, and therefore has many safety mechanisms built into the design. This allows cobots to have minimal guarding requirements compared with traditional robots. Industrial robots are generally better suited to handling heavy payloads and run faster than cobots; however, they are more difficult to integrate into a facility because they require large cages around the robot and more complex integration with existing systems and processes. - What are the best first tasks for cobots in small businesses (with high ROI)?

Repetitive, time-consuming, and stable tasks are good starting points for a cobot: Pick and Place, Packaging, Labeling, Machine Tending, Kitting, and Visual/Measurement Inspections. In general, the first “win” will be the process that creates the most bottlenecks and/or rework. - How much do cobots typically cost, and how quickly can a small business see ROI?

The cost of a cobot depends upon payload, reach, tools (end effectors/grippers), and integration into the specific application. While many small businesses measure Return On Investment (ROI) using labor-hour savings, throughput increases, and scrap reductions, these benefits can take anywhere from a few months to several years to realize, depending on how frequently the cobot operates and how well the specific task was defined. - Are cobots safe to use around employees, and what training is required?

While cobots can be very safe, safety is not an automatic feature. Many setups will still require a Risk Assessment and may require speed limiting, force limiting, sensors, and/or light guarding. Training will include Safe Operation, Basic Programming or Task Setup, and What to Do When the Cobots Stop Running or When Errors Occur. - How hard is it to integrate a cobot into an existing workflow (and can it be redeployed later)?

Many cobots can be easily integrated into an application when the task is consistent and input parameters are clearly defined (e.g., parts placed in a consistent tray, parts consistently oriented). However, relocating a cobot can be just as successful as integrating one, provided a new task definition, End-Of-Arm Tooling changes, and a new Safety Review are required.