How many of us have reached for a book on a top shelf, bent our elbow to take a drink, or twisted our wrist to open a door? Industrial robots are basically just an extension of that idea, with one major difference: they’re able to be built in a way that is significantly stronger, faster, and can accomplish the exact same motion over and over again (a million or more times) without ever getting tired. That’s really all there is to it. Those types of machines may seem like science fiction, but they are quietly changing the world around us.

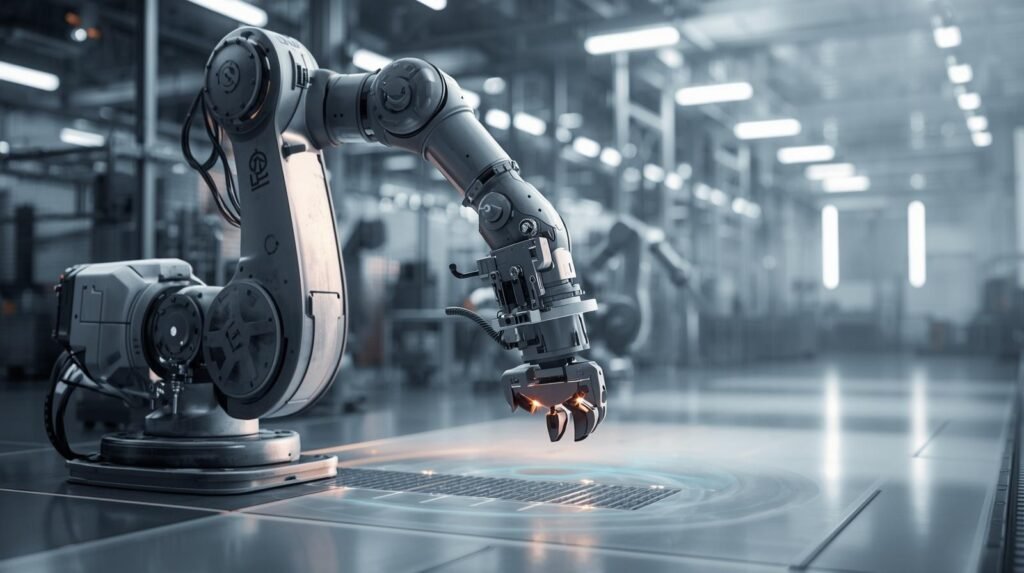

industrial robot arms: with articulated joints and a gripper performing automated tasks on a modern factory floor

Industrial robots on a factory floor today are much like employees who never get tired; they have a jointed mechanical body that reaches into cells to perform functions such as picking, placing, welding, or assembling various types of components. The ability of industrial robot arms to function effectively stems from their mechanically articulated design. An articulated design (i.e., an arrangement of several rotary joints) provides the necessary degrees of freedom to allow the arm to move about stationary objects in a cell; to reach parts at varying distances, orientations, and angles; and to repeatedly follow a predetermined path with high precision.

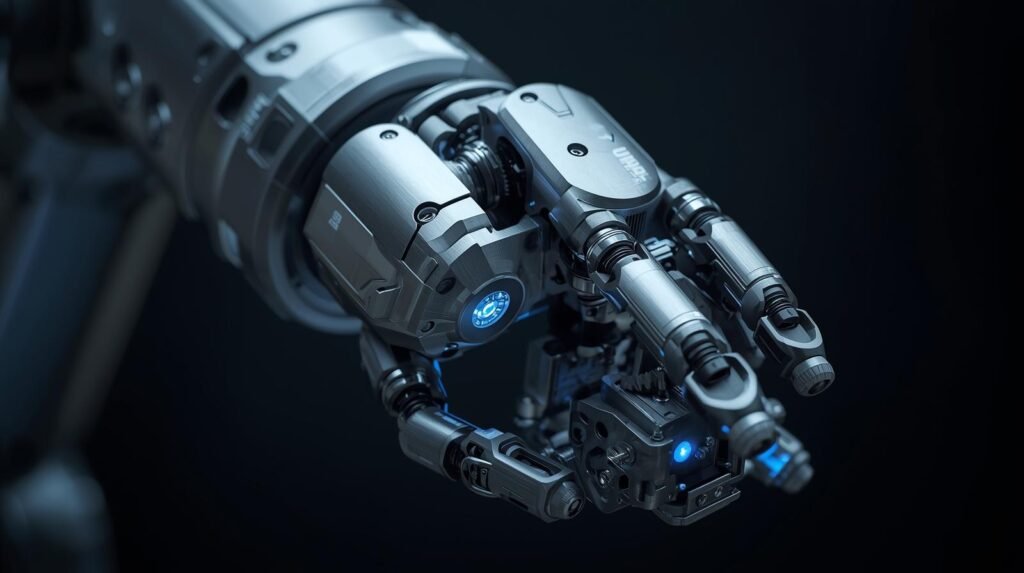

The “end” of the arm is typically referred to as the “hand.” In most cases, this hand consists of either a gripper or a specific tool. A parallel gripper is used to grasp a product component that is to be packaged, while a vacuum gripper is used to lift flat products (e.g., panels or cartons). For welding, painting, or screwdriving, the end effector is typically a torch, a spray gun, or a spindle. Therefore, industrial robot arms can quickly exchange end effectors and switch between tasks by changing tools, rather than replacing the entire robotic system.

To operate reliably, industrial robot arms integrate mechanical capabilities with sensing and control. Each joint contains encoders that measure its position and velocity. These measurements are provided to the controller, which uses them to maintain the arm on its planned trajectory. Additionally, force/torque sensors can be integrated into the robot to provide information about contact with the parts being inserted. Similarly, industrial robot arms may include vision systems to locate randomly oriented parts placed on a conveyor belt. All of these types of sensory information are fed into the robot’s control loop, enabling the robot’s motion to remain stable, smooth, and safe even as the load varies.

The “brain” of the operation resides in the controller cabinet; this is where the motion planner receives instructions and converts them into motion of the arm’s various parts. Industrial robot arms have traditionally been programmed using three methods: offline programming (teaching the robot without physical presence), hand-guiding (teaching the robot by manually guiding the end effector), or point-by-point teaching with a pendant. Once a routine has been successfully tested and proven reliable, the robotic system can be operated 24/7 with minimal cycle-to-cycle variability, significantly reducing the risk of defects caused by worker fatigue or process variability.

Safety in industrial robotics is becoming increasingly prevalent. Modern industrial robot arm deployments often include light curtains for guarding, allowing the robot to operate in areas adjacent to people. Collaborative systems also exist and reduce the speed and force of the robot’s actions when people are nearby. Risk assessments, emergency stops, and proper work-cell design all contribute to maintaining a safe, productive environment for employees and to production efficiency and predictability.

In everyday manufacturing operations, industrial robot arms are used for tasks that are repetitive, hazardous, or critical to the accuracy of the product – palletizing large heavy boxes, tending to CNC machines, providing uniform welds, and/or assembling smaller componentry. Due to their articulated nature and flexibility of their gripper(s), industrial robot arms provide a great deal of versatility, and their use of sensors and control software provides a great deal of intelligence. As manufacturers continue to seek higher production throughput and quality, industrial robot arms remain one of the best options for achieving automation at a scale commensurate with their production needs.

To the casual observer, industrial robot arms may appear to move with an almost surreal synchronicity. However, learning about how industrial robot arms work does not necessarily require an engineering degree. Rather than overwhelming readers with a mass of information, this guide breaks down the process of learning to work with industrial robot arms into seven easy-to-follow steps, from the robot’s physical body to its digital brain.

We will cover:

- The Body: The robot’s core structure.

- The Joints: How it achieves flexible movement.

- The Hand: The specialized tool at the end of the arm.

- The Brain: The computer that gives instructions.

- The Senses: How it sees and feels its environment.

- The Family: The different types of robots for different tasks.

- The Job: The real-world work they perform every day.

Summary

Industrial robotic arms are highly advanced versions of human arms designed to deliver high strength, speed, and precision. This guide explains how industrial robots function in 7 easy steps, beginning with the Manipulator (the rigid metal structure) that provides the strength, yet requires instructions to move. In Step 2 of this guide, the Joints and “Degrees of Freedom” will be explained, showing how the addition of more axes increases the flexibility of the arm, especially with common 6-axis articulated robots that can extend and orient tools in multiple directions.

In Step 3 of this guide, End-of-Arm Tooling (EOAT)—the swappable “Hand” portion of the robot that determines the task to be performed—will be discussed, including Grippers/Suction Cups, Welders, Screwdrivers, etc. Following that is the Controller (the “Brain”) of the robot, which stores Programs and may be instructed via a Handheld Teach Pendant to Record Movement.

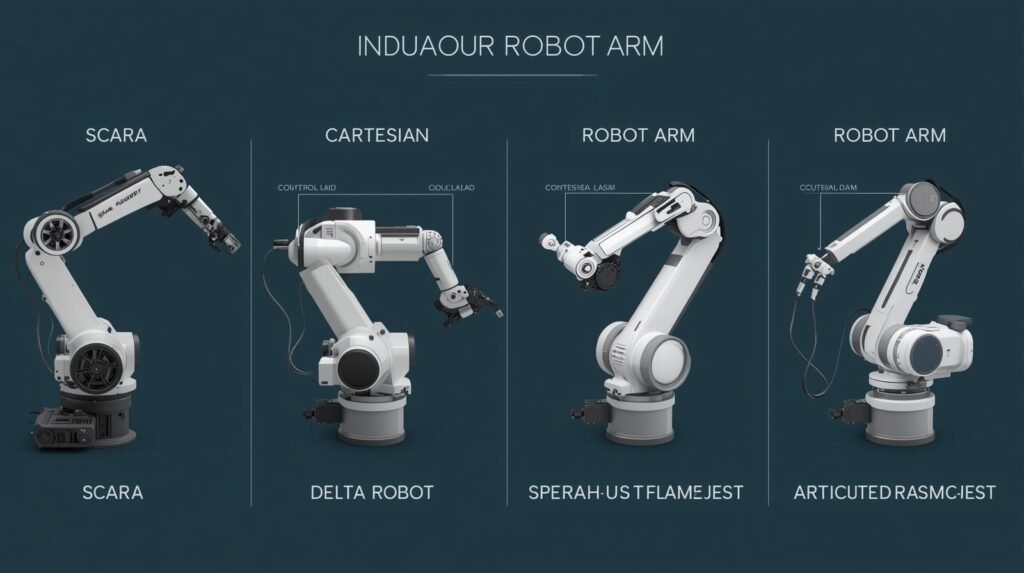

Robots use “Senses” such as Machine Vision and Force/Torque Sensors to enable the robot to visually determine Part Location, perform Quality Checks, and Apply a Gentle Touch (which also improves Safety). Step 5 of this guide discusses the Major Robot Families (Articulated Robots, SCARA Robots, and Collaborative Robots) and illustrates how each design type is suited to specific tasks. Steps 6-8 illustrate where industrial robots work every day and perform the “Dull, Dirty and Dangerous” jobs in numerous Industries; and discuss typical costs for purchasing an industrial robot and how the affordability of Cobots has expanded accessibility to the general public.

Industrial Robotics: Industrial robotics drives speed, accuracy, and reliability in manufacturing

Industrial Robotics is changing manufacturing by increasing the speed, accuracy, and reliability of processes, and doing so at scales that are difficult to achieve with human labor alone. In most plants, Industrial Robotics automates repetitive, dangerous, or precision-intensive tasks (e.g., welding, palletizing, machine tending, painting, inspection, and assembly). Most importantly, this enables manufacturers to maintain steady and consistent cycle times on an hour-to-hour basis. As a result, manufacturers experience increased throughput, reduced defect rates, and more stable production scheduling, particularly when demand varies.

Most automation cells use industrial robot arms that use rigid mechanical linkages and motion control to produce precise movements along programmed paths. The precision of industrial robot arms enables manufacturers to maintain tight tolerances, apply uniform weld beads, and place components in the exact same orientation each time. Additionally, Industrial Robotics significantly reduces process variability; for example, when industrial robot arms perform loading and unloading for CNC machines or presses, they eliminate minor timing variations that can contribute to tool wear, scrap, or bottlenecks.

While modern Industrial Robotics has become much more than just scripted motion, vision, force sensing, and sophisticated controllers enable industrial robot arms to adapt to real-world variables (e.g., parts arriving randomly oriented, slight positional drift on conveyor systems).

For example, by using advanced vision systems, force-sensing systems, and sophisticated controller systems, industrial robot arms can pick parts from bins, align components during insertion, and verify the presence/orientation of a part before moving to the next process step. Because of its flexibility, Industrial Robotics is viable not only for large-scale/high-volume production but also for mid-volume production with frequent changeovers and product variety.

Reliability is a second major benefit of Industrial Robotics. Unlike humans, Industrial Robot Arms do not get tired, so when performing repetitive sequences at consistent intervals, they provide consistent takt times and smoother downstream processes. Maintenance schedules, health checks, and diagnostic systems are additional methods to increase the availability of an Industrial Robot Arm for operation. Smart Work Cell Design enables the use of Industrial Robot Arms to enhance safety in areas where employees are exposed to heat, sharp objects, heavy items, or fumes, while allowing them to focus on inspection, quality control, and exception handling.

As manufacturers adopt lean manufacturing, improved product traceability and faster responses to evolving customer needs will drive continued growth in Industrial Robotics. From small cells to fully automated manufacturing lines, Industrial Robotics provides the core technologies needed to increase productivity, maintain higher quality standards, and remain competitive as a manufacturer. In many plants, this increased reliability is evident through the use of Industrial Robot Arms that operate with consistent accuracy and precision, enabling the timely completion of production runs.

Industrial Automation: Industrial automation reduces manual labor and boosts production efficiency

Industrial Automation increases production efficiency, consistency, and safety for manufacturing by reducing manual labor. It does this by combining equipment such as connected machines, sensors, control systems, and data feedback to maintain consistent production processes and minimize downtime. Maintaining a stable production process improves scheduling and planning, reduces rework, and ensures adherence to tighter delivery deadlines, regardless of changes in product demand.

Typically, on the shop floor, Industrial Automation combines Programmable Logic Controllers (PLCs), Drives, Conveyors, Vision Systems, and Robotics into Work Cells. One of the most important contributors to Work Cells is industrial robot arms. They are used for repetitive material handling functions such as Pick & Place, Palletizing, Packaging, and Machine Tending. For example, when an industrial robot arm loads a CNC machine or press on a fixed cycle, it eliminates small timing differences that typically cause bottlenecks, tool wear, and inconsistent product quality.829

In addition to producing products faster and cheaper, Industrial Automation also provides Quality Control Benefits. Inline Sensors and Cameras can measure product size, orientation, label information, and surface defects in real time, enabling defects to be identified prior to End-of-Line Inspection. In addition, if defects are found, the system can either reject defective products, notify personnel, or adjust process settings. On many Production Lines, industrial robot arms use Vision Guidance to accurately place materials for Assembly, Welding, Dispensing, or Inspection, improving Repeatability and reducing Scrap Rates.

Another benefit of Industrial Automation is that it enables safer job assignments. The heavy lifting, sharp edges, heat, fumes, and repetitive motions are removed from humans and placed in machines. When properly guarded, interlocked, and equipped with safety-rated controls, industrial robotic arms will continue to run 24/7, and human operators will continue to perform supervisory functions, replenish materials, and handle exceptions. This type of operation typically results in fewer accidents and addresses labor shortages without reducing production rates.

Industrial Automation also affects long-term equipment availability through diagnostic and predictive maintenance capabilities. Data collected by each machine (e.g., motor load, vibration, temperature, cycle count) may indicate early warning signs of failure, enabling maintenance personnel to plan part replacements before equipment failure. Whether your objective is to increase speed, consistency, and/or safety in your business operations, Industrial Automation offers a logical approach to upgrading your production process, using industrial robot arms as the most cost-effective and scalable component.

Robotic Arms: Robotic arms perform precise movements for repetitive industrial tasks

Robotic Arms are designed to perform precise, repeatable movements in industrial production environments. In terms of manufacturing, Robotic Arms provide benefits for tasks requiring consistent positioning, stable speeds, and predictable cycle time – especially when it is necessary to repeat the same motion thousands of times per shift. By performing repetitive operations, Robotic Arms reduce worker fatigue, lower variability, and enable consistent outputs.

Robotic Arms in manufacturing settings are commonly represented by articulated manipulators (joints) that are made up of shoulders, elbows, and wrists. These configurations enable movement from multiple directions to access parts relative to fixtures or obstacles within a work cell. Industrial Robot Arms are designed for stiffness, payload capacity, and repeatability, enabling proper programming to follow close paths (e.g., arc welds), dispense uniform paint or sealants onto surfaces, or position parts accurately during assembly.

The successful operation of robotic arms largely depends on their control systems. Real-time positional information from joint encoders enables smooth movement and accurate stopping. Industrial robot arms can also accommodate more complex step-by-step instructions, such as component placement on a conveyor or maintaining consistent insertion pressure, when equipped with additional sensors (e.g., cameras, force/torque) in addition to encoders. Because they can tolerate small deviations in component positioning, industrial robots are ideal for many applications where component placement varies slightly (e.g., automotive assembly lines).

Another important feature of robotic arms is end-of-arm tooling. There are several options available depending on the type of product being handled, e.g., grippers for picking and palletizing, vacuum cups for flat products, and specialized tools such as screwdrivers, polishers, and welders. Quick-change tool systems enable users to switch between jobs quickly, increasing the versatility of a single cell. This versatility is why industrial robot arms are widely used in automotive, electronics manufacturing, food packaging, and metal fabrication.

In addition to increased productivity, robotic arms can help improve safety and ergonomics. Heavy lifting, hot processes, handling sharp edges, or working in fume-producing environments can all be performed by industrial robots, with humans supervising operations, maintaining equipment, and managing any exceptions that arise. As manufacturers strive to improve quality and increase production rates, robotic arms remain a viable option for automating many repetitive, precision tasks at high volume.

Manufacturing Robots: Manufacturing robots handle welding, assembly, and material handling

Manufacturing Robots are integral to today’s manufacturing processes, performing welding, assembly, and material handling tasks more consistently and faster than their human counterparts.

High-volume production environments benefit greatly from the use of Manufacturing Robots, as they stabilize cycle time, improve product quality by reducing defects, and enable the production line to run continuously without interruption from variability associated with manual labor and worker fatigue.

Manufacturing Robots also enable higher production volume and improved delivery schedules by creating a stable production environment through automation.

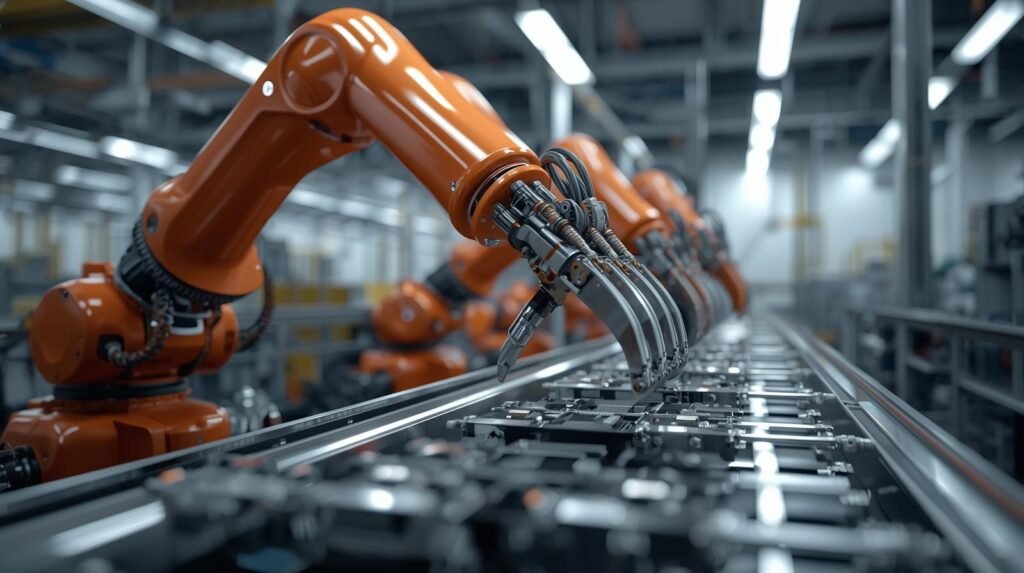

Welding applications using Manufacturing Robots improve weld quality by ensuring consistent torch angles, travel speeds, and paths. Thousands of welding cycles can be performed with consistent results. Industrial robot arm designs provide the stiffness and precision needed to maintain tight tolerances in challenging environments.

Assembly applications use manufacturing robots, along with vision and force feedback, to locate and assemble parts into a complete unit. Vision provides alignment of parts; force feedback provides the ability to install parts and apply screws with controlled torque. These assemblies are ideal for products with small parts or repetitive subassemblies. The industrial robot arms in these assembly cells can pick components from trays, position them accurately, and repeat the sequence with minimal variation, thereby improving product quality and traceability.

Material Handling is another application in which Manufacturing Robots excel. Palletizing, Depalletizing, Case Packing, Machine Tending, and pick-and-place applications (conveyor) are among the typical jobs that benefit from predictable timing and robust grip control. Industrial Robot Arms equipped with the correct End Effector (Parallel Gripper, Vacuum Tool, Magnetic Gripper, Custom Fixtures, etc.) can move heavy or difficult-to-manage loads quickly and effectively. Additionally, when Manufacturing Robots perform load/unload operations for CNC Machines and Presses, they can reduce downtime and increase Overall Equipment Effectiveness.

Depending on the Risk Assessment and Process Design, Manufacturing Robots may be integrated into a safe, well-contained workcell or positioned to provide closer interaction with people. In either scenario, Manufacturing Robots help move labor-intensive or hazardous processes away from employees, allowing them to monitor operations, perform quality inspections, and respond to exceptions. As manufacturers strive to implement leaner production systems and greater reliability, Manufacturing Robots continue to grow, and industrial robot arms remain at the forefront of this growth as primary tools for automated welding, assembly, and material transportation throughout the facility.

Robot Manipulators: Robot manipulators mimic human arm motion with high precision

Robot Manipulators have been engineered to replicate the dexterity of the human arm, but with the ability to repeat tasks with much greater precision and longevity than the human arm in industrial settings. For example, in manufacturing environments, Robot Manipulators can pick up parts, tools, and products and place them into specific positions along predetermined paths that can be repeatedly followed with minimal deviation. The widespread adoption of robot manipulators for tasks that require movement (e.g., a few millimeters or even a fraction of a millimeter) that will significantly impact overall process efficiency or lead to expensive rework is driven by their high repeatability.

The most common type of Robot Manipulator has a series of joints similar to those found on the human arm; i.e., shoulder, elbow, and wrist. These joints each provide a degree of freedom, giving the arm the flexibility to maneuver around various objects, reach parts from different angles, and position the tooling as needed.

As such, many manufacturers rely on industrial robot arms to perform this function in their plants, primarily due to their rigid design, motion stability at high speeds, and predictable performance under heavy loads. Because many manufacturing tasks are repetitive, when a specific task must be performed thousands of times in a row, industrial robot arms provide the accuracy and structural integrity required to meet specifications.

Control and sensory input enable Robot Manipulators to achieve high precision. Encoders provide real-time feedback on the position and speed of each joint, enabling the Robot Manipulator to smoothly coordinate motion across all axes. Additional sensor capabilities (e.g., force/torque measurements for delicate fits and/or camera-based vision systems for locating parts in non-repetitive positions) enable the Robot Manipulator to adapt to real-world variations while maintaining accurate positioning. In these applications, industrial robot arms can locate a part, properly align it, and then complete an insertion, welding, or dispensing action with consistent pressure and positioning.

End-of-arm tooling converts Robot Manipulators into customized workers. A gripper may be able to handle packaging and/or machine tending; a vacuum cup can pick flat objects; a custom tool can be designed for welding, painting, polishing, or screwdriving. With the ability to quickly swap out the end-of-arm tooling, the same Robot Manipulator can transition between tasks, which increases the versatility of the Robot Manipulator and decreases the time required for changeovers. The flexibility of Robot Manipulators makes them popular across industries such as assembly, automotive, electronics, metal fabrication, and general material handling.

Robot Manipulators enhance both worker safety and ergonomic efficiency by enabling heavy lifting, repetitive motion, and handling hazardous processes. With proper guarding, interlocks, and safety-rated controls, Robot Manipulators enable safe operation, allowing workers to focus on other critical aspects of the manufacturing process, such as supervising, performing quality checks, and managing exceptions. In today’s manufacturing environments, Robot Manipulators offer both human-like reach and dexterity, combined with repeatability and long-term durability, making industrial robot arms a vital component of automated manufacturing.

Step 1: Meet the Arm—It’s More Than Just a Metal Limb

An industrial robot’s manipulator is its physical body. The body consists of a mechanical arm with several joints and linkages. The manipulator is made of highly durable materials and is extremely stiff, enabling it to withstand the robot’s planned operations. A manipulator can be thought of as a very durable mechanical arm with the strength and durability of a human arm, but the ability to work without fatigue like humans do.

A manipulator has one main job – to repeat a physical process over and over again. For example, a manipulator could place thousands of electronic chips with precision on a circuit board. Another example is a manipulator used in a car plant to weld hundreds of car frames. Consistency is key to a manipulator’s success in manufacturing and to manufacturing’s success overall. Consistent performance is especially important when tasks are too physically demanding, too dangerous, or too boring for a person to complete.

The manipulator, however, cannot operate independently of a controller (the “brain” of the robot). It is simply the robot’s “arm,” waiting for a signal from the controller to act. The controller sends a precise signal to the arm telling it where to go and how to move to perform the next operation. However, the question remains: how does the controller send signals to the arm through its various movements (e.g., bends, twists)? The answer is simple: through the use of the robots’ joints.

Step 2: Unlocking Movement—What Are ‘Degrees of Freedom’?

Much like your arm, which is composed of a shoulder, elbow, and wrist, allowing it to move in many different ways, a robot arm has joints that allow it to bend and rotate. Each of these fundamental types of motion is referred to as a “degree of freedom” or an “axis”. The number of axes, therefore, is reflective of a robot’s overall flexibility. For example, a simple lever will typically only move in one direction (i.e., up and down) and thus would be considered to possess only one degree of freedom. Conversely, your arm is capable of reaching virtually any location due to its multiple axes of movement.

As such, a robot designed for relatively simple tasks, such as stacking boxes on a pallet, may utilize a relatively simple robot arm with only three or four axes. While the robot arm is highly efficient at performing such tasks on a single flat plane, it lacks the dexterity to handle more complex tasks, such as welding a curved car door or maneuvering through a small engine compartment. As a result, to accomplish these tasks, a robot must be able to twist and turn to achieve a higher level of dexterity. It is the increased reach and dexterity of a robot with additional axes (degrees of freedom) that enable it to perform more complex tasks.

Therefore, most industrial robots manufactured today are 6-axis articulated robots. Since the robot has six degrees of freedom, it can mimic the full range of motion of a human arm from the shoulder to the wrist. Therefore, it can position a tool at any orientation in the space surrounding the robot, thereby providing the dexterity required to assemble electronic components, paint complex surfaces, or handle fragile material. However, the robot arm’s ability to perform work depends on a tool being mounted at the end (i.e., at the wrist).

Step 3: The ‘Hand’ Swap—What is End-of-Arm Tooling (EOAT)?

A robot’s “hand” is actually a mounting point at which a variety of devices can be attached to perform tasks. These devices are called the End-of-Arm Tooling (EOAT) or end-effector; think of them as a robot’s “custom-built” swappable hand that performs one specific function. The EOAT transforms a robot from a simple moving entity into a specialized machine capable of performing a single function.

The best part about these tools is that they are interchangeable. The robot arm that welded a car chassis on Monday may be outfitted with a gripper on Tuesday to stack boxes. The ability to easily swap out the EOAT enables a wide variety of industrial robots to be used on the factory floor without each one looking significantly different. While the robot arm enables movement, the EOAT defines the robot’s purpose.

There are numerous options available when selecting an EOAT for your application:

- Grippers mimic the action of fingers or claws and enable the grasp and retention of objects.

- Suction cups utilize a vacuum to lift smooth, flat objects such as glass or cardboard.

- Welders join two pieces of metal using extreme heat.

- Screwdrivers automate fastening in electronics and automotive applications.

When choosing the correct EOAT, the type of task, the type of object the EOAT will interact with, and the payload of the robotic arm (the maximum weight the arm can safely support) should be taken into consideration.

Having the correct EOAT is only the first step toward success. The robot also needs to know whether to use its gripper gently to handle an egg or apply great force to grip a steel beam. The robot cannot receive instructions directly from the EOAT to determine the appropriate force to apply; therefore, the EOAT must include an instructional component. So, the question now is: How does the robot know exactly what to do with the EOAT?

Step 4: The ‘Brain’ in the Box—How Does a Robot Know What to Do?

The power behind this type of robotic arm is really a muscle without a brain, as the arm’s main control unit is a separate, very heavy-duty computer called the controller. The controller stores all the programs for the arm and tells it exactly which direction to move, at what speed, and when to start and stop. The controller can be thought of much like a video game console, and the arm is much like the characters in the game. The controller would run the game program and tell the character (arm) what to do and when.

The programming of the robotic arm is also a learning process rather than the development of a complex computer algorithm. In most cases, the user of the robotic arm will utilize a handheld device called a teach pendant. The teach pendant is a ruggedized, industrial-grade tablet with joysticks and buttons that allow the user to physically guide the robotic arm through the desired motion while simultaneously recording the arm’s position at each point. This type of programming is a significant component of any beginner-level robotic arm implementation guide, as it enables users to define a precise path for the arm to follow without requiring any programming.

Once the path is stored in the system, the robot executes it repeatedly and flawlessly, regardless of how many times it has been executed. It is this ability to remember a path and continue executing it perfectly over time that makes these types of machines so useful, not due to their ability to think, but rather because they are able to perform the same task every time, without tiring, even after millions of executions. This straightforward method of recording a path is a primary approach for programming a wide range of robots, including collaborative robots.

However, once a path has been developed and recorded by the robot, it remains valid only until something in the robot’s environment changes, such as a part being moved to a different location. To accommodate changing conditions, the robot must have some form of sensory input.

Step 5: Giving Robots ‘Senses’—How Do They See and Feel?

A perfectly good mindless robot can run the conveyor line fine until that oddball part shows up on the belt. When we can’t predict what will happen next, the robot will need some form of “sense.”

The most common sense used by robots is machine vision, which is essentially a form of perception.

Machine vision uses a fast camera and sophisticated software to help a robot find a product, find a defect on a product, and/or read the barcode on a product. Machine vision is the difference between a robot reaching for a cup’s location without knowing the cup is there and a robot locating the cup before reaching for it.

There are many jobs, however, that require a very delicate touch. If you were to try to put an egg into a carton using a machine designed to lift engine blocks, it would be nearly impossible. One way to solve this problem is to use advanced robots equipped with force/torque sensors (or force/torque sensing). Force/torque sensors are typically mounted at the robot’s wrist and measure force and torque (the resistance the robot exerts), allowing the robot to place a fragile item into a carton or stop its motion immediately if it encounters an unexpected object. In addition to being an important safety feature of modern robotic arm design, force/torque sensors enable robots to work safely near humans.

When used together, sight and feel enable a robot to be much more adaptable and capable than a purely mechanical device. Sight enables robots to handle delicate products and perform complex quality checks, while feel enables robots to operate more flexibly than before. With a brain, special hands, and new senses, the last piece of the puzzle is the mechanical design of the arm itself, and how that design changes based on the task the robot is required to complete.

Types of Industrial Robot Arms: Different robot arm types suit different industrial applications

Types of industrial robot arms vary widely in design and capabilities, since no single design can fit every manufacturing operation. The most important factors to consider when comparing an industrial robot’s capabilities are the payload, the reach, the speed, the repeatability, the footprint, and the necessary motion to accomplish the intended job; as such, selecting the right industrial robot for a given task is based on choosing the appropriate kinematics for the task at hand. In addition, understanding the types of industrial robot arms will help manufacturers select automated systems that deliver the greatest productivity and reliability for their unique applications.

The articulated robot is perhaps the most common type of industrial robot arm and generally has six degrees of freedom (axes). Because of their arm-like design, articulated robots are most commonly used for welding, painting, assembly, and machine tending, thanks to their ability to access parts from nearly any angle by reaching over fixtures. As such, articulated industrial robot arms are the preferred general-purpose, flexible option for many facilities where manufacturing operations may change frequently or where workpiece orientation is highly complex.

SCARA Robots fall into a category under the “Types of Industrial Robot Arms,” and are typically noted for their ability to perform quickly and accurately over a flat surface. These types of industrial robot arms are commonly used when high cycle volume is required in areas such as high-speed assembly, pick-and-place, and small-part handling. SCARA-type industrial robot arms can achieve rapid motion with high accuracy while operating within a relatively compact workspace.

The second category of “Types of Industrial Robot Arms” would be: Cartesian (Gantry) Systems. These systems move along the X, Y, and Z axes and are generally better suited for larger-envelope applications, heavier payloads, and simpler paths, such as palletizing, CNC load/unload, or conveying parts over long distances. The use of rails and/or overhead structures enables cost-effective deployment of Cartesian industrial robot arms for predictable motion.

The third category of “Types of Industrial Robot Arms” is Delta Robots, which are designed to deliver extremely rapid, lightweight pick-and-place capabilities and are often found in the food, beverage, and packaging industries. The use of a parallel link design allows for rapid acceleration and high throughput. The delta-type industrial robot arm has a limited payload and reach versus larger industrial robot arms.

The fourth category of “Types of Industrial Robot Arms” is Collaborative Robots (Cobots). Cobots are designed with safety features to operate in close proximity to humans. Cobots have become very popular in low- to medium-volume applications, where rapid redeployment is required, and both manual and automated processes are required simultaneously. Many end-users have seen success by utilizing multiple “Types of Industrial Robot Arms” on various stations throughout their facility to ensure that each process is utilizing the best industrial robot arms based on the speed, accuracy, and workload required for each specific application.

Step 6: Meet the Robot Family—Articulated vs. SCARA vs. Cobot

Just like how a sprinter’s body will be built for different reasons than a weightlifter, a robot arm will have a body design that fits the exact needs of what it’s being used for. The number of robotic arms in use for manufacturing is large and can generally be classified into several main categories. Once you identify the category of robot, you will find out nearly all of the information needed to understand its intended use based on its physical structure.

Articulated Robots are by far the most recognizable type of manufacturing robots. Because it has multiple joints that rotate, an articulated robot closely resembles the movement and appearance of a human arm, providing great flexibility. Due to this versatility, articulated robots are the most commonly found on production floors because they can reach over, under, and around obstacles. Because they can move through tight spaces and provide a wide range of motion, articulated robots are typically the preferred method for production tasks such as welding car frames, painting doors, and moving large parts between production lines.

On the other end of the spectrum is the SCARA Robot (Selective Compliance Assembly Robot Arm). A SCARA Robot is a speedy machine. It has two joints that allow it to move quickly back and forth on a flat surface, then extend a quill to the top and bottom of the surface. Although a SCARA Robot cannot move around obstacles as an articulated robot does, due to its design, a SCARA Robot is extremely fast and accurate for performing repetitive pick-and-place functions. This is why SCARA Robots are typically used for the assembly and packaging of small electronic devices and medical supplies.

A new member of the family of robots is beginning to impact the production floor: Collaborative Robots, or “Cobots.” Unlike traditional robots, which are confined to cages for safety, cobots are designed to operate alongside workers. Cobots also have advanced sensor systems that enable them to immediately stop operating upon contact with a person. This difference between the collaborative nature of cobots and the industrial nature of traditional robots enables humans and machines to work together in the same space, leveraging each other’s strengths: human problem-solving and robot endurance.

Step 7: The Real-World Job—Where Robots Are Hiding in Plain Sight

The image of a large, articulated robot welding a car frame is widely recognized; however, it represents only one aspect of the broader story of how robots have become increasingly prevalent in our workforce. The true story of the development of robotic automation has been developing in ways that may be less obvious. Robotic arms are the unnoticeable employees that ensure efficiency, safety, and consistency for many of the products we use every day, from the sterile environments where smartphone components are assembled and packaged to the food-processing plants where products such as our grocery items are processed and packaged.

So, why are robotic arms becoming visible throughout our lives? Generally, the reason is the “Three Ds “: Dull, Dirty, and Dangerous. These are the types of jobs that do not lend themselves well to human capabilities but are ideal for machines. A robot would make an ideal employee for performing repetitive tasks (e.g., putting thousands of identical caps on bottles, never losing concentration). Robots perform best with dirty jobs (i.e., spraying paint on furniture in a fume-filled booth), and lastly, and most importantly, they will take on jobs that are hazardous to human workers (i.e., lifting heavy objects or working with hazardous materials).

Therefore, this focus on the “Three D’s” brings the advantages of robotic automation in the manufacturing sector closer than many realize. Assembling circuit boards on a computer or the repetitive process of stacking boxes in a warehouse distribution center are both examples of robotic jobs. As technology becomes more accessible, a robotic arm for a small business is no longer considered science fiction. The importance of robotic arms is their ability to provide safe, affordable, and consistently produced products that have previously been available to consumers.

Your New ‘Robot Literacy’ and What Comes Next

You once thought of an industrial robot as one machine with many parts, and now you can see it as distinct parts working together – the physical “body” of the arm, the “hand” or tool used for the task, and the computer “brain” that directs every action it takes. You have transformed a mysterious machine into a system you can understand and a powerful extension of human intent.

This practical question naturally follows this discovery: how much does a robotic arm cost? Prices for these systems vary widely based on size, power, and speed. Complete systems for small businesses could range from about $25,000 for a small, collaborative model to over $200,000 for large arms designed to lift heavy car parts.

That lower price point is changing the game for robotic arms in small businesses. The rise in more affordable “cobots” (collaborative robots) has made it realistic for small business owners to purchase a robotic arm. Instead of seeing only a robot in a video or through a factory window, you will see much more than just a machine. You will be viewing an instrument that is designed to do those tedious, dirty, and dangerous jobs so that your human partner can concentrate on creative solutions and problems. Those arms are not here to replace the value we bring; they are here to enhance it in a collaborative future.

Conclusion

Industrial robot arms are not enigmatic devices — they are clearly defined, and functionally based systems which consist of a robust structure, flexible connections, an end-effector that is specific to a particular task, and a controller that converts commands into repeatable motions. When you understand degrees of freedom, end-of-arm tooling, and how robots are both taught and programmed, you will see why their value lies in them — they are able to generate predictable results at high speeds, over a long period of time, with no loss of performance due to fatigue.

Adding advanced “percepts” such as vision and force sensing to industrial robot arms enables them to extend their capabilities beyond repetitive motion to more intelligent, adaptable automation that can handle variability, protect product quality, and enhance safety. The design options available for industrial robot arms enable companies to select the correct type of robot for each unique application — articulated robots for high complexity reach applications; SCARA robots for rapid, planar movement; and collaborative robots (cobots) for safe and efficient human-robot interaction — rather than using a generic “one size fits all” approach.

Overall, the main message is that industrial robot arms excel at performing tasks that are either dull, dirty, or dangerous, and that limit production and pose hazards to personnel. As the cost of industrial robot arms continues to decrease, and as the process of deploying them continues to become easier, they are being made more accessible to more small to medium-sized businesses, which should enable teams to increase productivity, enhance the level of quality, and direct human resources toward supervision, troubleshooting, and innovation.

FAQs

- What is an industrial robot arm (manipulator)?

A robotic arm is composed of links and jointed elements and provides force and repeatability; however, it requires a controller (a computer) to determine how far and in which direction it should move. - What do “degrees of freedom” (axes) mean, and why does a 6-axis matter?

Degrees of freedom are a way for the robot to move (pivot and/or slide); therefore, additional degrees of freedom provide greater versatility. For this reason, a six-axis articulated robot can position a tool in multiple orientations; as such, these robots are commonly used in welding, painting, and complex assembly processes. - What is EOAT, and why is it so important?

End-of-Arm Tooling (EOAT) refers to the interchangeable “hands” on a robot, such as grippers, vacuum cups, welders, and screwdrivers. While the arm provides motion, the EOAT defines which task(s) the robot can accomplish. - How are industrial robot arms programmed?

Most are trained using a teach pendant; during training, an operator guides the arm to define the robot’s movement at key points and records the sequence. Once complete, the controller will store the robot’s path and enable it to repeatedly perform the same task at the same locations. In addition to teaching via a teach pendant, more advanced systems will utilize Offline Programming (OLP). - How do robots “see” or “feel” to handle real-world variation safely?

Machine Vision enables a robot to identify parts, recognize orientation, and examine quality. Force/Torque Sensors enable a robot to feel what it is doing by providing a sense of touch for delicate insertion into a part, controlled contact with a part, and safety when the robot encounters unexpected conditions.